You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Charging to 80% without a Satiator

- Thread starter Justin Fischer

- Start date

Ravi Kempaiah

Well-Known Member

- Region

- Canada

- City

- Halifax

So Ion and Polymer are the same chemistry?

No they are not.

The difference in chemistry is the electrolyte used. 18650 Li-ion cell use liquid organic electrolyte which helps them provide long cyclelife (because of additives used).

Li-polymer cells use polymer gel-like electrolyte. They both have different + and - but 18650 cells clearly offer more cyclelife.

Electrolyte is the bath in which these Li-ions have to swim back n forth and separates the anode and the cathode within a battery.

Here is a good article that explains the difference.

https://scottiestech.info/2015/06/21/lithium-polymer-vs-lithium-ion-batteries-whats-the-deal/

https://scottiestech.info/2015/06/21/lithium-polymer-vs-lithium-ion-batteries-whats-the-deal/

The difference is in the casing.. Lipo being a pouch, Li-ion being a cylindrical metal jacket, the chemistries are the same. From the article Mark F just posted. "“lithium-polymer” batteries are almost exactly the same as lithium-ion batteries, but they are instead contained in a flexible polymer casing. It’s basically just a repackaged lithium-ion battery. "So Ion and Polymer are the same chemistry? If so why the different names, just curious from ignorance.

bikerjohn

Well-Known Member

Here are some useful links excerpted from "Battery University":

https://batteryuniversity.com/index.php/learn/article/how_to_prolong_lithium_based_batteries

Note:Tables 2, 3 and 4 indicate general aging trends of common cobalt-based Li-ion batteries on depth-of-discharge, temperature and charge levels, Table 6 further looks at capacity loss when operating within given and discharge bandwidths. The tables do not address ultra-fast charging and high load discharges that will shorten battery life. No all batteries behave the same.

Table 2 estimates the number of discharge/charge cycles Li-ion can deliver at various DoD levels before the battery capacity drops to 70 percent. DoD constitutes a full charge followed by a discharge to the indicated state-of-charge (SoC) level in the table.

depth of discharge.* A partial discharge reduces stress and prolongs battery life, so does a partial charge. Elevated temperature and high currents also affect cycle life.

Note: 100% DoD is a full cycle; 10% is very brief. Cycling in mid-state-of-charge would have best longevity.

100% DoD~300 / 60080% DoD~400 / 90060% DoD~600 / 1,50040% DoD~1,000 / 3,00020% DoD~2,000 / 9,00010% DoD~6,000 / 15,000

Lithium-ion suffers from stress when exposed to heat, so does keeping a cell at a high charge voltage. A battery dwelling above 30°C (86°F) is considered elevated temperature and for most Li-ion a voltage above 4.10V/cell is deemed as high voltage. Exposing the battery to high temperature and dwelling in a full state-of-charge for an extended time can be more stressful than cycling. Table 3 demonstrates capacity loss as a function of temperature and SoC.

0°C98% (after 1 year)94% (after 1 year)25°C96% (after 1 year)80% (after 1 year)40°C85% (after 1 year)65% (after 1 year)60°C75% (after 1 year)60%

(after 3 months)

Most Li-ions charge to 4.20V/cell, and every reduction in peak charge voltage of 0.10V/cell is said to double the cycle life. For example, a lithium-ion cell charged to 4.20V/cell typically delivers 300–500 cycles. If charged to only 4.10V/cell, the life can be prolonged to 600–1,000 cycles; 4.0V/cell should deliver 1,200–2,000 and 3.90V/cell should provide 2,400–4,000 cycles.

On the negative side, a lower peak charge voltage reduces the capacity the battery stores. As a simple guideline, every 70mV reduction in charge voltage lowers the overall capacity by 10 percent. Applying the peak charge voltage on a subsequent charge will restore the full capacity.

In terms of longevity, the optimal charge voltage is 3.92V/cell. Battery experts believe that this threshold eliminates all voltage-related stresses; going lower may not gain further benefits but induce other symptoms. (See BU-808b: What causes Li-ion to die?) Table 4 summarizes the capacity as a function of charge levels. (All values are estimated; Energy Cells with higher voltage thresholds may deviate.)

Guideline: Every 70mV drop in charge voltage lowers the usable capacity by about 10%.

Note: Partial charging negates the benefit of Li-ion in terms of high specific energy.

[4.30][150–250][110–115%]4.25200–350105–110%4.20300–500100%4.15400–70090–95%4.10600–1,00085–90%4.05850–1,50080–85%4.001,200–2,00070–75%3.902,400–4,00060–65%3.80See note35–40%3.70See note30% and less

Experiment: Chalmers University of Technology, Sweden, reports that using a reduced charge level of 50% SOC increases the lifetime expectancy of the vehicle Li-ion battery by 44–130%.

Most chargers for mobile phones, laptops, tablets and digital cameras charge Li-ion to 4.20V/cell. This allows maximum capacity, because the consumer wants nothing less than optimal runtime. Industry, on the other hand, is more concerned about longevity and may choose lower voltage thresholds. Satellites and electric vehicles are such examples.

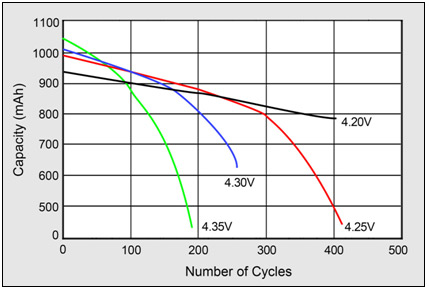

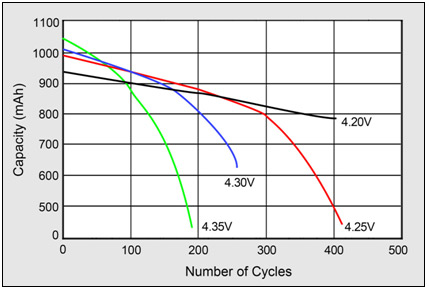

For safety reasons, many lithium-ions cannot exceed 4.20V/cell. (Some NMC are the exception.) While a higher voltage boosts capacity, exceeding the voltage shortens service life and compromises safety. Figure 5 demonstrates cycle count as a function of charge voltage. At 4.35V, the cycle count of a regular Li-ion is cut in half.

Figure 5: Effects on cycle life at elevated charge voltages. Higher charge voltages boost capacity but lowers cycle life and compromises safety.

Source: Choi et al. (2002)

Besides selecting the best-suited voltage thresholds for a given application, a regular Li-ion should not remain at the high-voltage ceiling of 4.20V/cell for an extended time. The Li-ion charger turns off the charge current and the battery voltage reverts to a more natural level. This is like relaxing the muscles after a strenuous exercise. (See BU-409: Charging Lithium-ion)

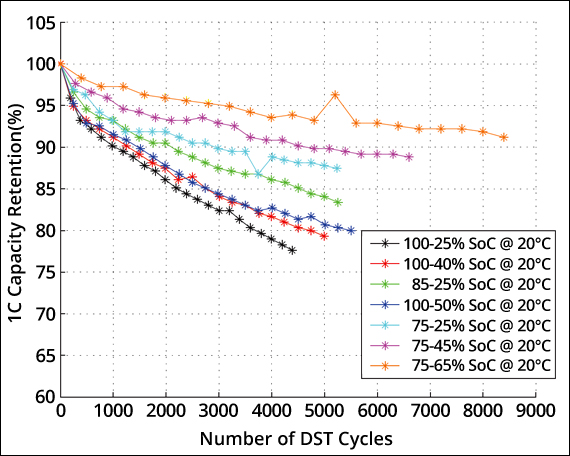

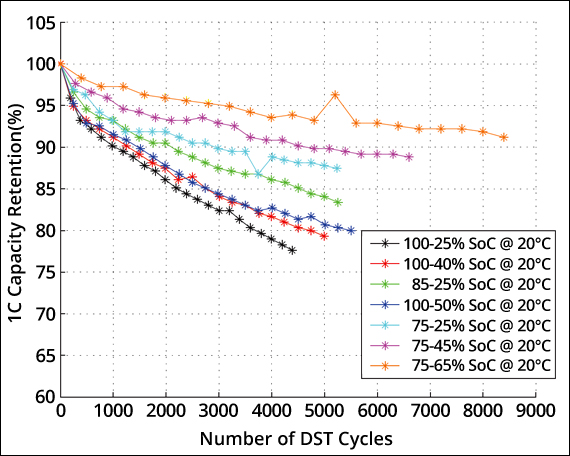

Figure 6 illustrates dynamic stress tests (DST) reflecting capacity loss when cycling Li-ion at various charge and discharge bandwidths. The largest capacity loss occurs when discharging a fully charged Li-ion to 25 percent SoC (black); the loss would be higher if fully discharged. Cycling between 85 and 25 percent (green) provides a longer service life than charging to 100 percent and discharging to 50 percent (dark blue). The smallest capacity loss is attained by charging Li-ion to 75 percent and discharging to 65 percent. This, however, does not fully utilize the battery. High voltages and exposure to elevated temperature is said to degrade the battery quicker than cycling under normal condition. (Nissan Leaf case)

Figure 6: Capacity loss as a function of charge and discharge bandwidth.*

Figure 6: Capacity loss as a function of charge and discharge bandwidth.*

Charging and discharging Li-ion only partially prolongs battery life but reduces utilization.

Case 1: 75–65% SoC offers longest cycle life but delivers only 90,000 energy units (EU). Utilizes 10% of battery.

Case 2: 75–25% SoC has 3,000 cycles (to 90% capacity) and delivers 150,000 EU. Utilizes 50% of battery. (EV battery, new.)

Case 3: 85–25% SoC has 2,000 cycles. Delivers 120,000 EU. Uses 60% of battery.

Case 4: 100–25% SoC; long runtime with 75% use of battery. Has short life. (Mobile phone, drone, etc.)

Courtesy: ResearchGate – Modeling of Lithium-Ion Battery Degradation for Cell Life Assessment.

https://www.researchgate.net/public..._Battery_Degradation_for_Cell_Life_Assessment

* Discrepancies exist between Table 2 and Figure 6 on cycle count. No clear explanations are available other than assuming differences in battery quality and test methods. Variances between low-cost consumer and durable industrial grades may also play a role. Capacity retention will decline more rapidly at elevated temperatures than at 20ºC.

Only a full cycle provides the specified energy of a battery. With a modern Energy Cell, this is 250Wh/kg, but the cycle life will be compromised. All being linear, the life-prolonging mid-range of 85-25 percent reduces the energy to 60 percent and this equates to moderating the specific energy density from 250Wh/kg to 150Wh/kg. Mobile phones are consumer goods that utilize the full energy of a battery. Industrial devices, such as the EV, typically limit the charge to 85% and discharge to 25% to prolong battery life. (See Why Mobile Phone Batteries do not last as long as an EV Battery)

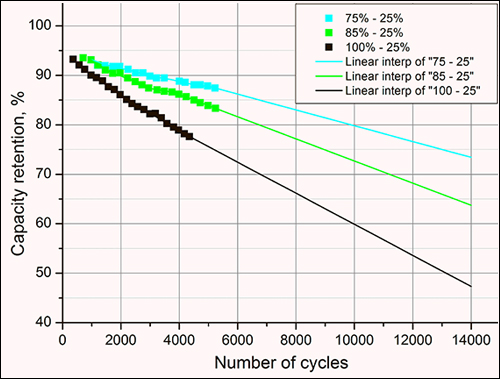

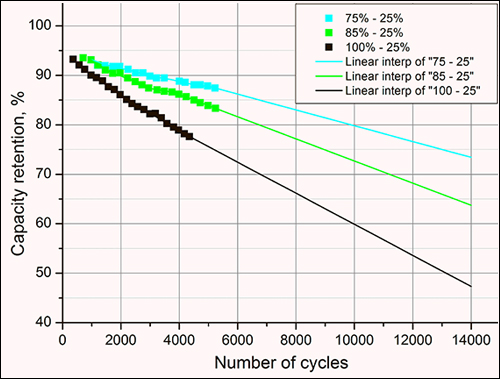

Figure 7 extrapolates the data from Figure 6 to expand the predicted cycle life of Li-ion by using an extrapolation program that assumes linear decay of battery capacity with progressive cycling. If this were true, then a Li-ion battery cycled within 75%–25% SoC (blue) would fade to 74% capacity after 14,000 cycles. If this battery were charged to 85% with same depth-of-discharge (green), the capacity would drop to 64% at 14,000 cycles, and with a 100% charge with same DoD (black), the capacity would drop to 48%. For unknown reasons, real-life expectancy tends to be lower than in simulated modeling. (See BU-208: Cycling Performance)

Figure 7: Predictive modeling of battery life by extrapolation.

Li-ion batteries are charged to three different SoC levels and the cycle life modelled. Limiting the charge range prolongs battery life but decreases energy delivered. This reflects in increased weight and higher initial cost.

With permission to use. Interpolation/extrapolation by OriginLab.

Battery manufacturers often specify the cycle life of a battery with an 80 DoD. This is practical because batteries should retain some reserve before charge under normal use. (See BU-501: Basics about Discharging, “What Constitutes a Discharge Cycle”) The cycle count on DST (dynamic stress test) differs with battery type, charge time, loading protocol and operating temperature. Lab tests often get numbers that are not attainable in the field.

https://batteryuniversity.com/index.php/learn/article/bu_808b_what_causes_li_ion_to_die

https://batteryuniversity.com/index.php/learn/article/how_to_prolong_lithium_based_batteries

Note:Tables 2, 3 and 4 indicate general aging trends of common cobalt-based Li-ion batteries on depth-of-discharge, temperature and charge levels, Table 6 further looks at capacity loss when operating within given and discharge bandwidths. The tables do not address ultra-fast charging and high load discharges that will shorten battery life. No all batteries behave the same.

Table 2 estimates the number of discharge/charge cycles Li-ion can deliver at various DoD levels before the battery capacity drops to 70 percent. DoD constitutes a full charge followed by a discharge to the indicated state-of-charge (SoC) level in the table.

Depth of discharge

Discharge cycles

(NMC / LiPO4)

Table 2: Cycle life as a function ofDischarge cycles

(NMC / LiPO4)

depth of discharge.* A partial discharge reduces stress and prolongs battery life, so does a partial charge. Elevated temperature and high currents also affect cycle life.

Note: 100% DoD is a full cycle; 10% is very brief. Cycling in mid-state-of-charge would have best longevity.

100% DoD~300 / 60080% DoD~400 / 90060% DoD~600 / 1,50040% DoD~1,000 / 3,00020% DoD~2,000 / 9,00010% DoD~6,000 / 15,000

Lithium-ion suffers from stress when exposed to heat, so does keeping a cell at a high charge voltage. A battery dwelling above 30°C (86°F) is considered elevated temperature and for most Li-ion a voltage above 4.10V/cell is deemed as high voltage. Exposing the battery to high temperature and dwelling in a full state-of-charge for an extended time can be more stressful than cycling. Table 3 demonstrates capacity loss as a function of temperature and SoC.

Temperature

40% charge

100% charge

Table 3: Estimated recoverable capacity when storing Li-ion for one year at various temperatures. Elevated temperature hastens permanent capacity loss. Not all Li-ion systems behave the same.40% charge

100% charge

0°C98% (after 1 year)94% (after 1 year)25°C96% (after 1 year)80% (after 1 year)40°C85% (after 1 year)65% (after 1 year)60°C75% (after 1 year)60%

(after 3 months)

Most Li-ions charge to 4.20V/cell, and every reduction in peak charge voltage of 0.10V/cell is said to double the cycle life. For example, a lithium-ion cell charged to 4.20V/cell typically delivers 300–500 cycles. If charged to only 4.10V/cell, the life can be prolonged to 600–1,000 cycles; 4.0V/cell should deliver 1,200–2,000 and 3.90V/cell should provide 2,400–4,000 cycles.

On the negative side, a lower peak charge voltage reduces the capacity the battery stores. As a simple guideline, every 70mV reduction in charge voltage lowers the overall capacity by 10 percent. Applying the peak charge voltage on a subsequent charge will restore the full capacity.

In terms of longevity, the optimal charge voltage is 3.92V/cell. Battery experts believe that this threshold eliminates all voltage-related stresses; going lower may not gain further benefits but induce other symptoms. (See BU-808b: What causes Li-ion to die?) Table 4 summarizes the capacity as a function of charge levels. (All values are estimated; Energy Cells with higher voltage thresholds may deviate.)

Charge level (V/cell)

Discharge cycles

Available stored energy

Table 4: Discharge cycles and capacity as a function of charge voltage limit. Every 0.10V drop below 4.20V/cell doubles the cycle but holds less capacity. Raising the voltage above 4.20V/cell would shorten the life. The readings reflect regular Li-ion charging to 4.20V/cell.Discharge cycles

Available stored energy

Guideline: Every 70mV drop in charge voltage lowers the usable capacity by about 10%.

Note: Partial charging negates the benefit of Li-ion in terms of high specific energy.

[4.30][150–250][110–115%]4.25200–350105–110%4.20300–500100%4.15400–70090–95%4.10600–1,00085–90%4.05850–1,50080–85%4.001,200–2,00070–75%3.902,400–4,00060–65%3.80See note35–40%3.70See note30% and less

Experiment: Chalmers University of Technology, Sweden, reports that using a reduced charge level of 50% SOC increases the lifetime expectancy of the vehicle Li-ion battery by 44–130%.

Most chargers for mobile phones, laptops, tablets and digital cameras charge Li-ion to 4.20V/cell. This allows maximum capacity, because the consumer wants nothing less than optimal runtime. Industry, on the other hand, is more concerned about longevity and may choose lower voltage thresholds. Satellites and electric vehicles are such examples.

For safety reasons, many lithium-ions cannot exceed 4.20V/cell. (Some NMC are the exception.) While a higher voltage boosts capacity, exceeding the voltage shortens service life and compromises safety. Figure 5 demonstrates cycle count as a function of charge voltage. At 4.35V, the cycle count of a regular Li-ion is cut in half.

Figure 5: Effects on cycle life at elevated charge voltages. Higher charge voltages boost capacity but lowers cycle life and compromises safety.

Source: Choi et al. (2002)

Besides selecting the best-suited voltage thresholds for a given application, a regular Li-ion should not remain at the high-voltage ceiling of 4.20V/cell for an extended time. The Li-ion charger turns off the charge current and the battery voltage reverts to a more natural level. This is like relaxing the muscles after a strenuous exercise. (See BU-409: Charging Lithium-ion)

Figure 6 illustrates dynamic stress tests (DST) reflecting capacity loss when cycling Li-ion at various charge and discharge bandwidths. The largest capacity loss occurs when discharging a fully charged Li-ion to 25 percent SoC (black); the loss would be higher if fully discharged. Cycling between 85 and 25 percent (green) provides a longer service life than charging to 100 percent and discharging to 50 percent (dark blue). The smallest capacity loss is attained by charging Li-ion to 75 percent and discharging to 65 percent. This, however, does not fully utilize the battery. High voltages and exposure to elevated temperature is said to degrade the battery quicker than cycling under normal condition. (Nissan Leaf case)

Charging and discharging Li-ion only partially prolongs battery life but reduces utilization.

Case 1: 75–65% SoC offers longest cycle life but delivers only 90,000 energy units (EU). Utilizes 10% of battery.

Case 2: 75–25% SoC has 3,000 cycles (to 90% capacity) and delivers 150,000 EU. Utilizes 50% of battery. (EV battery, new.)

Case 3: 85–25% SoC has 2,000 cycles. Delivers 120,000 EU. Uses 60% of battery.

Case 4: 100–25% SoC; long runtime with 75% use of battery. Has short life. (Mobile phone, drone, etc.)

Courtesy: ResearchGate – Modeling of Lithium-Ion Battery Degradation for Cell Life Assessment.

https://www.researchgate.net/public..._Battery_Degradation_for_Cell_Life_Assessment

* Discrepancies exist between Table 2 and Figure 6 on cycle count. No clear explanations are available other than assuming differences in battery quality and test methods. Variances between low-cost consumer and durable industrial grades may also play a role. Capacity retention will decline more rapidly at elevated temperatures than at 20ºC.

Only a full cycle provides the specified energy of a battery. With a modern Energy Cell, this is 250Wh/kg, but the cycle life will be compromised. All being linear, the life-prolonging mid-range of 85-25 percent reduces the energy to 60 percent and this equates to moderating the specific energy density from 250Wh/kg to 150Wh/kg. Mobile phones are consumer goods that utilize the full energy of a battery. Industrial devices, such as the EV, typically limit the charge to 85% and discharge to 25% to prolong battery life. (See Why Mobile Phone Batteries do not last as long as an EV Battery)

Figure 7 extrapolates the data from Figure 6 to expand the predicted cycle life of Li-ion by using an extrapolation program that assumes linear decay of battery capacity with progressive cycling. If this were true, then a Li-ion battery cycled within 75%–25% SoC (blue) would fade to 74% capacity after 14,000 cycles. If this battery were charged to 85% with same depth-of-discharge (green), the capacity would drop to 64% at 14,000 cycles, and with a 100% charge with same DoD (black), the capacity would drop to 48%. For unknown reasons, real-life expectancy tends to be lower than in simulated modeling. (See BU-208: Cycling Performance)

Figure 7: Predictive modeling of battery life by extrapolation.

Li-ion batteries are charged to three different SoC levels and the cycle life modelled. Limiting the charge range prolongs battery life but decreases energy delivered. This reflects in increased weight and higher initial cost.

With permission to use. Interpolation/extrapolation by OriginLab.

Battery manufacturers often specify the cycle life of a battery with an 80 DoD. This is practical because batteries should retain some reserve before charge under normal use. (See BU-501: Basics about Discharging, “What Constitutes a Discharge Cycle”) The cycle count on DST (dynamic stress test) differs with battery type, charge time, loading protocol and operating temperature. Lab tests often get numbers that are not attainable in the field.

https://batteryuniversity.com/index.php/learn/article/bu_808b_what_causes_li_ion_to_die

I would be a little weary of cycle claims. The way they cycle the battery is under a very low amp draw and in a relatively short period of time. So they will tend to get better results than in real world say ebikes do. There numbers are however right in that you get more cycles with less charge. But to what end would you go. If you only charge once or twice a month, then your battery might suffer reduced cycle life from age. Some of these articles talk about 18650 cells lasting 3 years before age kicks in. I don't know how much of that is true, I think our packs should be good for 4 or 5 years , but age is relative to usage so your results will vary. I am a casual ebiker and I charge my battery all the way before I ride. A charged battery last me 3 or 4 rides or 1 to 2 weeks before I get down to 1 bar and need to charge again. It's winter now so I am riding less. If I charged daily I would do things a little differently.

Justin Fischer

Active Member

I'm missing something. Juiced says for the 52V that 80% is 55V and 20% is 45V. The chart above says 80% is 56V and 20% is 52V. It also states that 0% on the 52V is around 46V. I think the stock setting for low voltage cutoff on the Juiced CCX is around 42V. I bumped it up to 45V for my needs. If the chart above is correct then the 45V threshold I set is actually below 0%. Something makes zero sense here.

How did you bump it up to 45v? I have the 52v pack and this happens in my settings:

I just realized this thread exploded. I'll update the original post once I catch up on the replies.

So...based on Mark's chart. I've been starting my ride with a 67% charge and finishing with a 3% charge. I thought I had been starting with an 75% charge and finishing with a 35% charge. My ride is 20 miles round trip with hills both ways. I have 48v 19ah battery pack and ride the CCS. I would typically start my rides with 50.7 volts and finish my ride with 44 volts.

Mark, is the below chart correct from your perspective?

View attachment 28604

If this is correct, why do we think the Satiator manufacturer's math, which they use to program the 80% rules into the charger, is wrong? The 80% value is the same, but the 20% value is way off.

Last edited:

bikerjohn

Well-Known Member

Setting the minimum voltage cut-off at a specific minimum voltage "under load" is a helpful factor for extending a Li-Ion batteries useful life.

The controversy seems to be over what is the 20% voltage specification. There is a variance between the different charts that have been brought forth.

My understanding is that part of the confusion has been a batteries voltage reading "in-use" -vs- "resting state". On a Juiced bike with the advanced matrix display one can see the voltage reading during their ride -vs- the voltage reading after they finish the ride. This variance seems to be a normal condition of the BMS re-balancing any variance in the battery cells.

Setting any minimum voltage is easy with the Juiced advanced matrix settings. The factory default cut-off setting for the 52 Volt battery was 44 Volts. Upping any minimum from there is adding useful "life cycles" for the battery. So, for my 52V 19.2Ah battery, I've set my minimum voltage cut-off "under load" to 45 volts.

The controversy seems to be over what is the 20% voltage specification. There is a variance between the different charts that have been brought forth.

My understanding is that part of the confusion has been a batteries voltage reading "in-use" -vs- "resting state". On a Juiced bike with the advanced matrix display one can see the voltage reading during their ride -vs- the voltage reading after they finish the ride. This variance seems to be a normal condition of the BMS re-balancing any variance in the battery cells.

Setting any minimum voltage is easy with the Juiced advanced matrix settings. The factory default cut-off setting for the 52 Volt battery was 44 Volts. Upping any minimum from there is adding useful "life cycles" for the battery. So, for my 52V 19.2Ah battery, I've set my minimum voltage cut-off "under load" to 45 volts.

bikerjohn

It makes me happy to see you now understand what I was trying to say. Your 45v cutoff is probably a good one but you know how to tell if it's good by checking your resting voltage. Once you figure out your LVC, you can forget about it and enjoy your bike.

One other thing that wasn't touched on is the need to do a full charge every so often for those of you doing the 80% thing. A full charge helps keep your cells balanced and lets the BMS know what a fully charged packs voltage is so it can be a little more accurate in the numbers it gives you. I'm sure some will have opinions on when you should do this but I think once in 10 charges should be fine.

It makes me happy to see you now understand what I was trying to say. Your 45v cutoff is probably a good one but you know how to tell if it's good by checking your resting voltage. Once you figure out your LVC, you can forget about it and enjoy your bike.

One other thing that wasn't touched on is the need to do a full charge every so often for those of you doing the 80% thing. A full charge helps keep your cells balanced and lets the BMS know what a fully charged packs voltage is so it can be a little more accurate in the numbers it gives you. I'm sure some will have opinions on when you should do this but I think once in 10 charges should be fine.

bikerjohn

Well-Known Member

On today's short ride I started out with 53.5 volts in the battery pack. It was chilly out at 36 degrees and a significant 13 mph Northerly wind.Setting the minimum voltage cut-off at a specific minimum voltage "under load" is a helpful factor for extending a Li-Ion batteries useful life.

The controversy seems to be over what is the 20% voltage specification. There is a variance between the different charts that have been brought forth.

My understanding is that part of the confusion has been a batteries voltage reading "in-use" -vs- "resting state". On a Juiced bike with the advanced matrix display one can see the voltage reading during their ride -vs- the voltage reading after they finish the ride. This variance seems to be a normal condition of the BMS re-balancing any variance in the battery cells.

Setting any minimum voltage is easy with the Juiced advanced matrix settings. The factory default cut-off setting for the 52 Volt battery was 44 Volts. Upping any minimum from there is adding useful "life cycles" for the battery. So, for my 52V 19.2Ah battery, I've set my minimum voltage cut-off "under load" to 45 volts.

The Erie Canal gets drained in the Winter around the Spencerport/Brockport area:

The Erie Canal gets drained in the Winter around the Spencerport/Brockport area:

When I finished the ride I photographed the displayed values:

15 minutes later the voltage had stabilized to 51.7 volts and the graph shows about 50% battery capacity remaining:

SirJonathan

Active Member

bikerjohn

It makes me happy to see you now understand what I was trying to say. Your 45v cutoff is probably a good one but you know how to tell if it's good by checking your resting voltage. Once you figure out your LVC, you can forget about it and enjoy your bike.

One other thing that wasn't touched on is the need to do a full charge every so often for those of you doing the 80% thing. A full charge helps keep your cells balanced and lets the BMS know what a fully charged packs voltage is so it can be a little more accurate in the numbers it gives you. I'm sure some will have opinions on when you should do this but I think once in 10 charges should be fine.

In Tesla-land this is recommended practice. When new, your 85kwH Tesla battery should provide a maximum of 265 miles of range. Often you'll see people posting about the fact that their full charge is only 256 or some other arbitrary number lower than 265. The recommendation is always to let your battery run very low (under 50 miles of range left) and then fully charge to 100%. After this rebalancing the user almost always immediately posts back that they can now see 260+ range miles. Sometimes it's even more drastic with the user "gaining" another 20 miles.

(I know it's Apples to Oranges but as an aside, with very little concern for my 7 year-old Tesla 85KwH battery I can charge to 263 range miles. Out of the maximum of 265 miles you'll note that I have lost about 1% of my original battery capacity in 7 years and over 80,000 miles. So much for the thousands of early detractors asking what we're all going to do with those batteries in 5 years when they are at 20% of their original capacity.)

bikerjohn

Well-Known Member

How did you bump it up to 45v? I have the 52v pack and this happens in my settings:

If I can take a guess, You need a software update on your CCS display.

Your display unit programming and read out information seem to be different from the CCX.

Perhaps you would benefit from a software update in light of the fact that you are using the 52V 19.2Ah battery.

My matrix display allows me to set a minimum voltage higher than 43 volts by pressing the "+" button when in the "Low Volts" window.

The CCX display also has 7 power modes 0, ECO, 1, 2, 3, S, R ; The CCX display also has a useful power consumption readout indicating "Wh/mile"

REPLY

Justin Fischer

Active Member

So Juiced actually published their own chart, which is way off what any of us came up with. Not exactly helping the confusion. https://support.juicedbikes.com/hc/...966591-My-52V-battery-is-always-shown-as-full

Attachments

PastorDave

New Member

Wow I had no idea just charging the battery would be this complicated. I am totally lost. I never was great at math. Perhaps e-biking is not for me.

Similar threads

- Replies

- 19

- Views

- 6K

- Replies

- 1

- Views

- 3K

- Replies

- 12

- Views

- 4K