Tom@WashDC

Well-Known Member

- Region

- USA

- City

- Loudoun County, VA.

A while back I decided I wanted to carry a 2nd OEM battery to swap when my primary ran low. A new battery costs about $415. I formed a battery cradle to fit at the bottom of the downtube made from solid rubber.

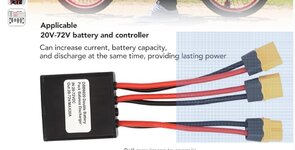

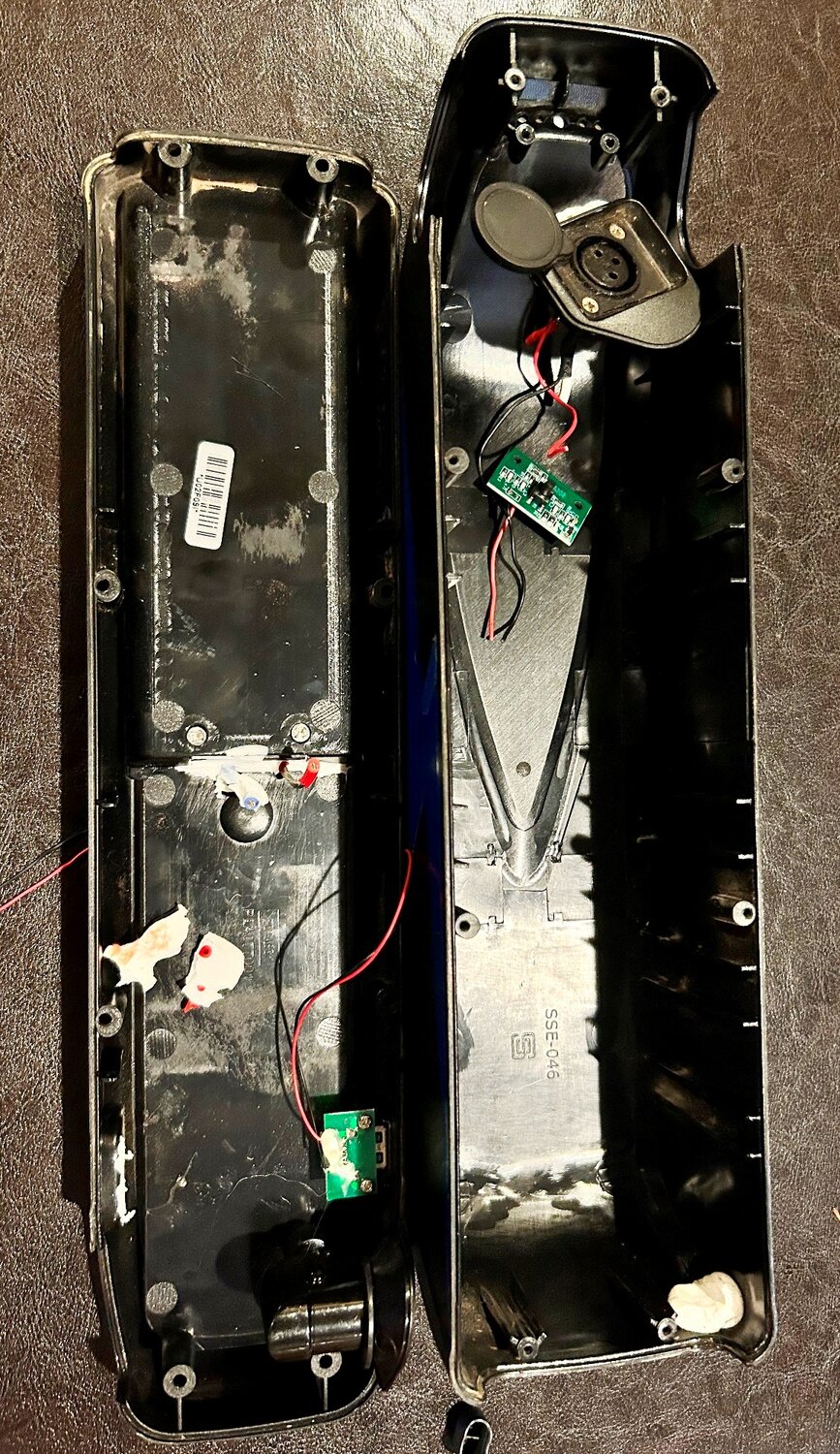

Then I figured that since I had a perfectly good Hailong battery lying around that I wasn't using, maybe I could use the battery pack instead of spending $425. I could install a Battery Balancer ($48) and run both batteries at the same time. So I removed the battery pack from the Hailong case, soldered in a different charging fitting, soldered an XT60 connector for the main power, and wrapped the pack in black Gorilla tape, with a layer of high density foam on the one side of the battery that will rest on the downtube.

Then I installed the Battery Balancer/Connector inside the frame in the motor cavity, running a connecting wire with an XT60 connector to connect the 2nd battery.

Secured the battery with rubberized velcro straps. It works like a charm. I actually have more available power on demand, and 35amp hours! Incredible range.

Then I figured that since I had a perfectly good Hailong battery lying around that I wasn't using, maybe I could use the battery pack instead of spending $425. I could install a Battery Balancer ($48) and run both batteries at the same time. So I removed the battery pack from the Hailong case, soldered in a different charging fitting, soldered an XT60 connector for the main power, and wrapped the pack in black Gorilla tape, with a layer of high density foam on the one side of the battery that will rest on the downtube.

Then I installed the Battery Balancer/Connector inside the frame in the motor cavity, running a connecting wire with an XT60 connector to connect the 2nd battery.

Secured the battery with rubberized velcro straps. It works like a charm. I actually have more available power on demand, and 35amp hours! Incredible range.