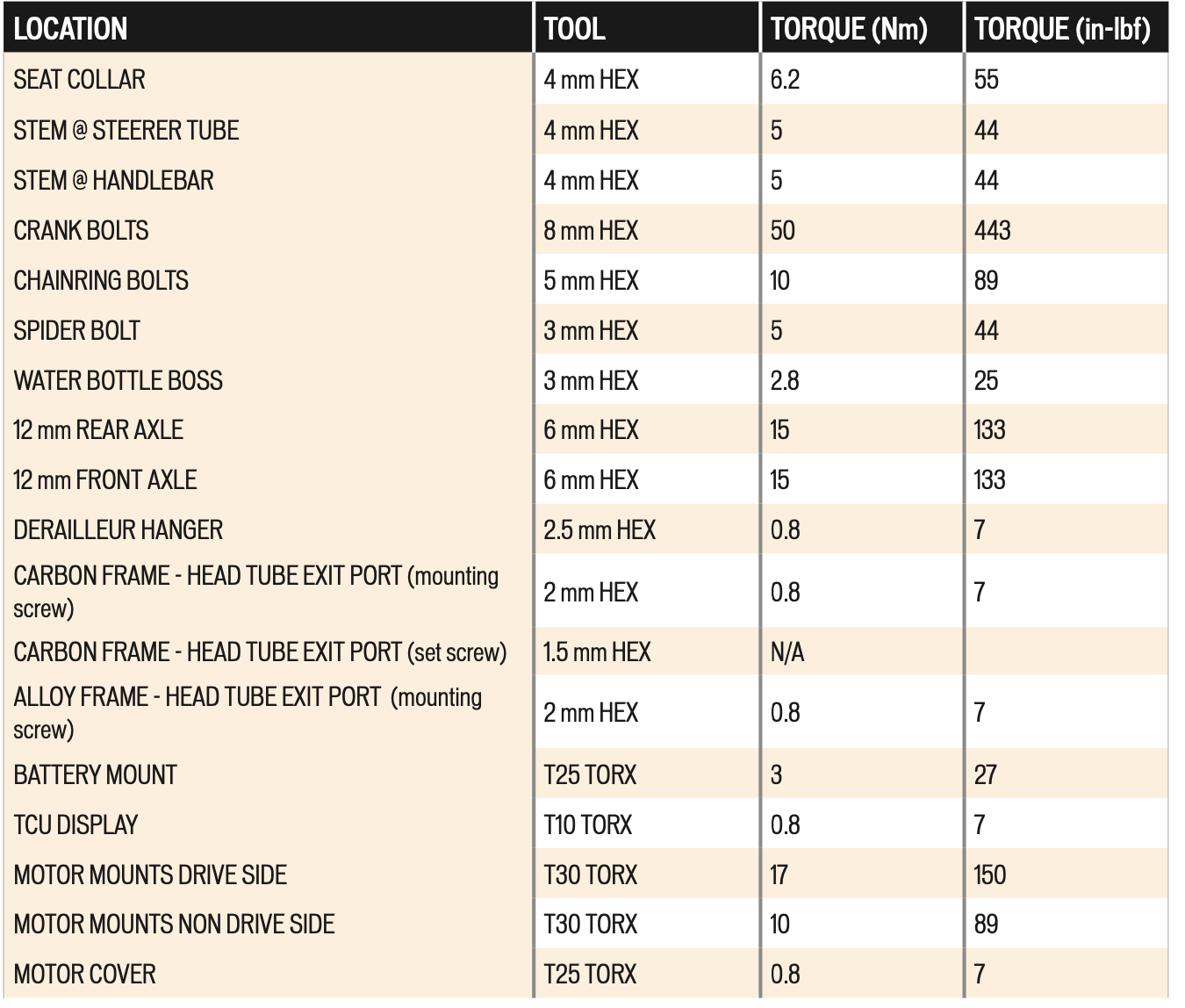

I am in the process of checking the torque on all of the bolts on this bike. The manual shows the axle hex size as 6 mm. The hex size with both the front and rear wheels on my bike are 5 mm instead of 6 mm. Should this be torqued at 133 inch lbs.? The reason I am asking is the torque as it was assembled is about 90 inch lbs. To determine the present torque value, I gradually increased the torque setting on the torque wrench incrementally starting at about 50 till I got up to 90 inch lbs. where I could feel a slight turning till the wrench clicked. Also, the manual that came with the bike also appears to be an older manual since it shows the older TCU. The online manual also appears to be an older manual. The bike has about 250 miles at this time with no problems with the wheels. There is a knocking noise when in Sport or Turbo while climbing a steep grade(>6 percent) that the bike shop cannot duplicate. Everything has been torqued(including the single chain ring bolt, spider bolt?) except for the axles. The motor cover is inserted properly and torqued. I have two Inch lb. torque wrenches to verify accuracy.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2022 Creo Axle Torque

- Thread starter mmwada

- Start date

Stefan Mikes

Well-Known Member

- Region

- Europe

- City

- Mazovia, Poland

10-12 Nm (90-100 lb-in) is all what you need.

mschwett

Well-Known Member

- Region

- USA

I am in the process of checking the torque on all of the bolts on this bike. The manual shows the axle hex size as 6 mm. The hex size with both the front and rear wheels on my bike are 5 mm instead of 6 mm. Should this be torqued at 133 inch lbs.? The reason I am asking is the torque as it was assembled is about 90 inch lbs. To determine the present torque value, I gradually increased the torque setting on the torque wrench incrementally starting at about 50 till I got up to 90 inch lbs. where I could feel a slight turning till the wrench clicked. Also, the manual that came with the bike also appears to be an older manual since it shows the older TCU. The online manual also appears to be an older manual. The bike has about 250 miles at this time with no problems with the wheels. There is a knocking noise when in Sport or Turbo while climbing a steep grade(>6 percent) that the bike shop cannot duplicate. Everything has been torqued(including the single chain ring bolt, spider bolt?) except for the axles. The motor cover is inserted properly and torqued. I have two Inch lb. torque wrenches to verify accuracy.

View attachment 151930

i believe there are a couple different through axles used on creos, so the 5mm is probably normal, although the part specified definitely says 6. are you sure it’s 5mm? which creo and which through axle?

i see several other specialized bikes with a 5mm hex in the TA, and every carbon specialized through axle road/gravel bike seems to list 15nm/133 inch lbs. i can think of no reason not to follow the spec, and consistent torque at the through axles will also result in consistent rotor alignment.

kahn

Well-Known Member

- Region

- USA

- City

- northWET washington

I believe that I wrote about this in another thread. But I got a flat (rear, of course, although it probably does not matter) and could not loose the faux quick release lever on my Creo. It was so damn tight. I tried pounding it with my bike shoe. I was in a marina and finally I found someone with a hammer and that did it.

Dazmanturbo

Well-Known Member

I had the Creo Carbon comp that I put on a diet when I purchased it and the first thing I swapped was the axles. The axles with the levers are weighty, so I swapped over the the allen key version and less than half the weight. The rear 148 x 12 was easy to get with 6mm bolt. The front was impossible to find at the time being 110 x 12, so I ended up making my own from cut down 142 x 12 and cutting extra thread. 3 years on, still works 100% and has a 5 mm bolt. I always nip them on allen key just as they bite. If they do work lose, believe me you will feel it. Never had one come lose which I have tightened, just one which I forget to tighten, so that was on me...

I've pondered how I’d handle a similar scenario.I believe that I wrote about this in another thread. But I got a flat (rear, of course, although it probably does not matter) and could not loose the faux quick release lever on my Creo. It was so damn tight. I tried pounding it with my bike shoe. I was in a marina and finally I found someone with a hammer and that did it.

On my Domane the lever insert is held magnetically so it’s easy to orient its hex key to be able to step on it with my heel to start loosening the axle.

It dawned on me the lever is on a hex bolt - allowing similar reorientation.

Still good to periodically make sure it can be removed in the field without a hammer.

The bike model is SL Comp Carbon. I am not positive that it is 5 mm but the socket does fit securely. What I am positive about is. it isn't a 6 mm. Both front and rear axles have the 5 mm hex size.i believe there are a couple different through axles used on creos, so the 5mm is probably normal, although the part specified definitely says 6. are you sure it’s 5mm? which creo and which through axle?

View attachment 152164

i see several other specialized bikes with a 5mm hex in the TA, and every carbon specialized through axle road/gravel bike seems to list 15nm/133 inch lbs. i can think of no reason not to follow the spec, and consistent torque at the through axles will also result in consistent rotor alignment.

I did contact Specialized support and they did verify the torque spec. At the same time, I also questioned the 5mm hex bolt size but that concern wasn't addressed.

I guess the concern now is the smaller hex size with a torque spec that is higher than most thru axles. Given that the 5 mm hex size would have less hex socket surface versus 6 mm and the axle bolt is an aluminum alloy, is there an even greater chance of the axle bolt hex rounding off? I guess it is a good thing that the lever to remove the bolt is there?

mschwett

Well-Known Member

- Region

- USA

The bike model is SL Comp Carbon. I am not positive that it is 5 mm but the socket does fit securely. What I am positive about is. it isn't a 6 mm. Both front and rear axles have the 5 mm hex size.

View attachment 152262

I did contact Specialized support and they did verify the torque spec. At the same time, I also questioned the 5mm hex bolt size but that concern wasn't addressed.

I guess the concern now is the smaller hex size with a torque spec that is higher than most thru axles. Given that the 5 mm hex size would have less hex socket surface versus 6 mm and the axle bolt is an aluminum alloy, is there an even greater chance of the axle bolt hex rounding off? I guess it is a good thing that the lever to remove the bolt is there?

probably a result of the lever design. many of the carbon bikes don’t have the lever, and the axle design has plenty of room for a 6mm hex. I personally replaced those bulky levers with a Robert Axle Project through axle, much sleeker and lighter. 61g of weight savings and way better looking. of course, the torque spec is 12nm leading to an existential crisis, do you use the spec from the frame, or the fastener?

replacement axles on my creo

OEM axles on my other specialized carbon bike

probably a result of the lever design. many of the carbon bikes don’t have the lever, and the axle design has plenty of room for a 6mm hex. I personally replaced those bulky levers with a Robert Axle Project through axle, much sleeker and lighter. 61g of weight savings and way better looking. of course, the torque spec is 12nm leading to an existential crisis, do you use the spec from the frame, or the fastener?depending on the material, 15nm is actually pretty high for a 5mm hex cap, but not for a 6mm, which also makes me feel better about the replacement ones…

Yeah, I suspect one isn't supposed to apply that torque to the 5mm hex, but instead remove the lever and apply the torque to the underlying hex head with a socket driver or crowfoot wrench.

I prefer the Bontrager Switch thru axle idea where the lever is a 6mm hex key and is held magnetically in the thru axle. Keep one on the bike if you don't care about the weight, or remove it if you do.

mschwett

Well-Known Member

- Region

- USA

Yeah, I suspect one isn't supposed to apply that torque to the 5mm hex, but instead remove the lever and apply the torque to the underlying hex head with a socket driver or crowfoot wrench.

I prefer the Bontrager Switch thru axle idea where the lever is a 6mm hex key and is held magnetically in the thru axle. Keep one on the bike if you don't care about the weight, or remove it if you do.

ahhh, there’s a 6mm head under there?!? i thought it was one piece.

mschwett

Well-Known Member

- Region

- USA

ahhh i see what you mean. that would be a little inconvenient on-bike since most mini tool kits or multitools don’t have a 12mm socket lol.More like 12mm.

kahn

Well-Known Member

- Region

- USA

- City

- northWET washington

I will have to look it over and see how the hip bone is connected to the leg bone!Strictly speaking, the lever itself is a 12mm socket.

Being a two-piece design, if necessary you can reposition the lever to be able to (carefully) press down on it with your foot to start loosening the thru axle.

Am I correct to assume that the 5 mm hex is a bolt that secures the lever to the axle? If it is, then when torquing the 5 mm hex we are torquing 2 bolts (lever and axle bolt)? Not to complicate things, but is this the reason for the higher torque value? If we were to torque only the 12 mm axle bolt with the 12 mm head, the torque spec would be around 100 instead of 133 inch lbs.? If this is correct, it still circles back to why does the manual say it is a 6 mm hex?Strictly speaking, the lever itself is a 12mm socket.

Being a two-piece design, if necessary you can reposition the lever to be able to (carefully) press down on it with your foot to start loosening the thru axle.

Yes, the screw securing the lever to the axle takes a 5mm hex.

I'd suggest the only assumption you make is that Specialized's technical writers aren't in sync with engineering/distribution.

My 2022 Vado 4.0 has the conventional style without the lever and accepts a 6mm hex key.

User manual torque value entry is identical; 15Nm / 133in-lb

I'd suggest the only assumption you make is that Specialized's technical writers aren't in sync with engineering/distribution.

My 2022 Vado 4.0 has the conventional style without the lever and accepts a 6mm hex key.

User manual torque value entry is identical; 15Nm / 133in-lb

Thanks, this is good to know. I just included a 5 mm Allen wrench in my saddle bag incase I have difficulties with the lever and have to reposition it.Yes, the screw securing the lever to the axle takes a 5mm hex.

I'd suggest the only assumption you make is that Specialized's technical writers aren't in sync with engineering/distribution.

My 2022 Vado 4.0 has the conventional style without the lever and accepts a 6mm hex key.

User manual torque value entry is identical; 15Nm / 133in-lb

Similar threads

- Replies

- 8

- Views

- 1K