Question for you both....

With the Rohloff having a rating of maximum input torque of 130 Nm... and the Ultra exceeding that by 23% rated at 160Nm output... Did you inquire if this may void any potential warranty claims?

I'm assuming that either way it wasn't enough to dissuade you... but any concerns?

Correct, all things being equal it would not have dissuaded me. So everything I say must be taken with a "grain of salt". I did some basic research using online torque calculators, watching videos (

like this), Reading Sheldon Brown's

Torque In The Drivetrain, understanding the Rohloff gear sizing chart, talking to the Rohloff dealer, and some Rohloff owners that are running the hub with 2.0-2.5KW systems for at least a year.

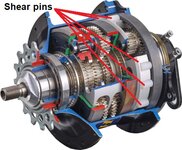

First off, the Rohloff hub utilizes 9 nylon Coupling Pins that will shear (shear pins) if you exceed some unknown torque value. The pins are replaceable. The hubs internal components are safe from damage as the hub will spin uselessly without spinning the tire. So no problem there. You will need to walk home and fix it, or send it off to get fixed. So what we are talking about here is always the amount of force needed to shear the nylon Coupling Pins, not break the hub.

In talking to Peter, owner of the Peter White Cycles, he indicated that he has never had to replace the pins. He also indicated that Rohloff does make steel Coupling Pins for Tandem Bike Hubs where the torque forces can be extremely high at the cranks. Two humans can easily exceed 160nm at the cranks. If Rohloff does makes steel pins, I would posit that the hub torque rating may be engineered for torque forces that are higher than the specs would indicate. Just a thought.

Peter is a wheel builder since 1969, and his web site claims that he along with Propel Bikes, are the "

the only authorized service centers for Rohloff in North America". In my search for a dealer that carried the Rohloff Measuring kit, I called many "distributors" and bike stores that carried Rohloff parts, none of them could get me the kit in a timely fashion. I finally contacted the Rohloff rep in Germany for US, GB, AUS, and he put me in touch with Peter White Cycles. Peter has a shipment coming from Rohloff Germany on a weekly basis. He apparently does a robust business with Rohloff.

Back to the torque forces. So the torque on the Ultra is purported to be peak 160nm at the crank (output torque). The torque force that you need to be concerned about is the torque that is mediated by the transmission, and delivered to the rear cog (hub input torque), which is not the same as the crank output torque. In most applications it will be less than the torque at the crank. The torque at the rear cog that is applied at a standstill is the most important consideration. That is where the rotational force of the hub is trying to overcome the dead weight of the bike and rider at a standstill, the most probable point of over-torque failure.

The final input torque forces at the rear cog can be calculated using various online calculators and formulas, and I did run a few scenarios. After reading and calculating, and talking to owners and the dealer, I figured that I would not be exceeding the Rohloff recommended input torque at the cog. If I applied maximum motor torque, and human power, from a standstill, maybe, but I don't see that happening. And, if I know my German Engineering, the hub is probably over engineered compared to the spec rating. The worse case scenario is that I might end up replacing coupling pins one day if I really over-torque the hub, but I won't damage the hub. While it would be a pain to replace pins, the first time around, I would consider it another part of the learning curve, and not likely to happen.

I followed the Rohloff guide to sizing the rear cog. "

To prevent overstraining the hub, a minimum sprocket ratio of 1.90 must be used" (a ratio of 2.5 for Tandems. see page 19 of manual). I have a 40T chainring. 40/1.9 = 21T Cog in the rear. I am using a 16T rear cog, so my ratio of 2.5 is well above the 1.9 ratio threshold. This combo seems to work for me. Anecdotally, after 400 miles I have never felt anything close to undue strain on the system. I know what excessive "strain" feels like as I've managed to snap four chains, and destroy the hub pawls twice while riding a Bafang BBSHD or my Bafang Ultra. Obviously there are other factors involved in those events such as chain wear/age, hub/pawl wear, being caught in the wrong gear on a hill in the wrong PAS level, faulty derailleur, and finally, my initial lack of experience with ebike riding/shifting in the beginning. With the Rohloff hub, I find I am never caught in the wrong gear, and I have never needed to use my throttle.

After reading all the theory, collecting anecdotal evidence, and riding the hub for 500+ miles, I am not overly concerned about shearing the coupling pins. I read on the board

here where Pushkar from WattWagons maxed out the Rohloff and the Kindernay hubs up to 250Nm on a 2,300 watt bike, from a dead stop, without shearing the pins, or damaging either hub.

I hope this rambling post helps, and I will do a 500 mile review shortly.

~Damn the torpedoes, full steam ahead!