indianajo

Well-Known Member

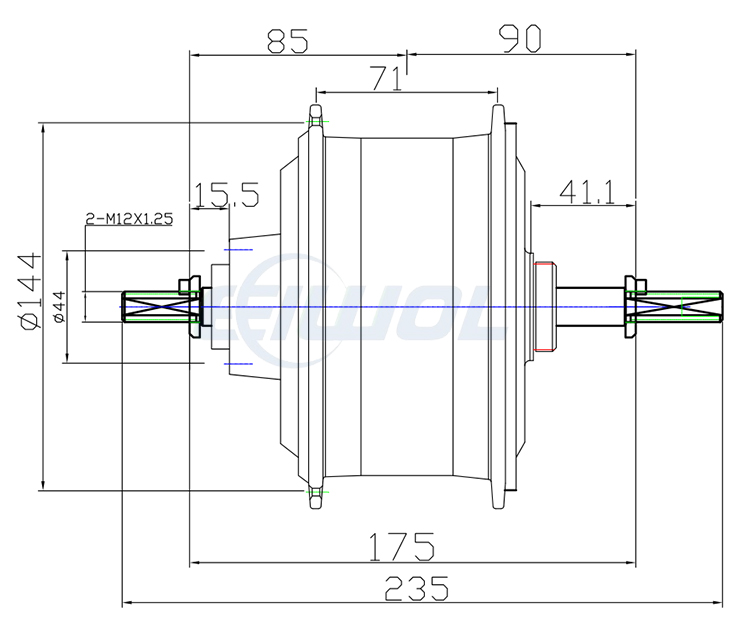

I see eiwol didn't bother to provide you with a spoke hole diameter, nor the number of spokes. Nice drawing with dimensions that don't matter. Since you have one, you will have to take a caliper and measure the spoke diameter, then count the number of spokes. the axle is in the way of a dial or digital caliper, you'll also need a transfer caliper or divider www.starrett.com/category/precision-measuring-tools/calipers,-dividers--trammels/1113 to take the measurement. With those numbers, and the offset which they did give, you can put the numbers in a spoke calculator and get a nice big lie. I tried various spoke calculators, and the # of crosses is important. I miss counted that, got the wrong length spokes. I shortened and those were too short. The 3rd batch was about right, but some installed longer than others and I had to use the extra long 12 mm spoke nipples to take up the slack. Bike shops have spoke threading machines. My LBS charges $200 to lace a wheel. Which is why I did it myself when I bought an IGH. If you can get a pre laced wheel, it will be a *****y double layer one which requires extra long stems on tubes available in my town only over the internet. Plus the prelaced wheels come with *****y imitation steel spokes, which require adjustment sometimes. The wheel I built I used DTswiss spokes, which were not a maintenance problem since I don't jump curbs.5. If I upgrade my hub motor do you normally just restring your spokes or get a bike shop to install it or do you have to get it pre-strung on a rim?

7. How do I make sure I don't over run the hub motor and burn it out? I am looking at a 1000w sustained motor with peak about 1500w

Hub motors burn out if run at full throttle up a grade or through high snow or powder sand for too long. So possibility depends on your terrain. Mac motor quotes 25 minutes at max throttle, 25 amps. My $221 ebikeling 1300 W geared hubmotor + controller + display would put out 30 amps, but the torque was not that much more at 30 than at 20 amps. So when ebikeling motor wore out the gears, I bought a Mac12 with a controller that only puts out 500 W. It will start on 15% grades at 330 lb gross even so. I ride up >77 hills on my 30 mile commute to summer property. Since they are rolling hills with many downgrades, the motor doesn't burn up on a 3.5 hour trip.

I deleted the *****y ebikeling display, it was inaccurate, shut off coasting down hills which is 40% of the time on my route, and fogged over from the rain. I have red-yellow-green LED's in the throttle to show battery voltage.

Second ahicks motion, buy motor-controller-display from same source to insure compatibiity. If display-controller only, you have to match the motor connector by looking at those tiny pictures on the alibaba/ebay/amazon ad. Might work, might not. The white rectangular 6 pin connector was the same between by ebikeling kit and a DD 1000 w power wheel kit I bought , so I used the ebikeling motor and the throttle/controller from the DD kit. Displays are much more finicky, even a software revision may make a controller & display incompatible.

Last edited: