Ann M.

Well-Known Member

Do you hear an annoying grinding or clicking noise coming from the rear wheel of your bike or you can't shift into all of the gears? You need a simple rear derailleur adjustment. Besides having a quieter ride, your chain, derailleur and rear sprockets will last longer saving money by avoiding more expensive repairs. You only need a few tools: a Phillip's or flat head screwdriver, some small metric wrenches (3-6 mm) or an adjustable wrench and a 5mm hex wrench to adjust a derailleur.

What causes the derailleur to go out of adjustment? With a new bike or cable, there's some “stretch” or slack of the shifter cable that develops over time resulting in poor shifting. With an older or dry, oxidized cable, friction inside the cable housing can make each shift feel difficult so the cable may need lubrication or replacement. Also check for a frayed cable or broken housing or a broken jockey roller; these will need to be replaced. An unfortunate impact could smack the derailleur hard enough to bend it or the derailleur mount (the hanger), possibly even bending a rear dropout on the frame in towards the rear wheel. More often it's the hanger made with a lighter material that's the culprit and bends. No amount of adjustments will help unless the derailleur is hanging straight.

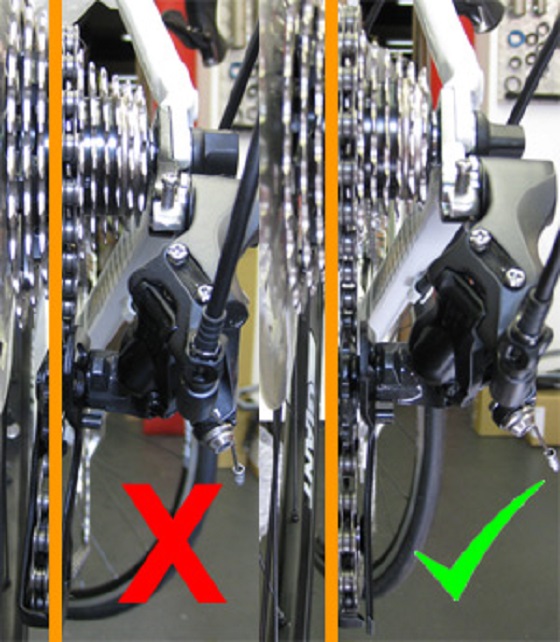

Take a quick look from behind the bike at wheel level to check the vertical alignment of the two pulleys or jockey rollers inside the cage to verify that the derailleur is hanging straight. The lower pulley should be directly underneath the upper one positioned just below the sprockets or the chain will not track properly. If this checks out, then you're ready to begin the adjustments. (Note: some derailleurs with a longer cage designed to accommodate a wide gear range may have the lower roller offset outwards just a bit.)

If the derailleur or hanger is bent, a bike shop mechanic will use a special derailleur alignment tool to straighten it. In the case of a bent hanger that is not part of the derailleur but bolted onto the frame, it may be better and less expensive to replace it rather than bend it. However, at home or on the road you can readily remove the derailleur and carefully bend the tab on the hanger with a set of pliers or an adjustable wrench for a temporary fix. Don't try to straighten the derailleur by bending the pulley cage; you're more likely to damage the cage or misalign the pulleys.

Begin the derailleur adjustment by loosening the gear cable at the derailleur clamp bolt, then reset the barrel adjusters at the derailleur and/or shifter body by screwing them all the way down (clockwise), then screw them out (counter-clockwise) one full turn. This gives you room to do fine adjustments of the cable tension when needed. Leave the cable loose while you adjust the limiter screws for a more accurate adjustment.

Shift into the highest gear (the smallest sprocket) by turning the cranks. If the chain doesn't seat on this sprocket smoothly or looks like it will jump off into the gap between the frame and the sprocket, then you need to adjust the set screws. Look for the pair of small screws on the derailleur body and find the one marked with an “H.” Turn this screw clockwise to limit the motion of the derailleur outwards if the chain tries to jump into the frame and counter-clockwise if the chain won't land firmly on the outer sprocket. The upper pulley or jockey roller should now be directly underneath the smallest sprocket when you check it from behind.

Next, press in on the derailleur to help shift into the lowest gear, your largest sprocket. If the chain won't shift onto that sprocket or tries to shift into the spokes adjust the other set screw marked “L” so that the upper pulley is centered directly below the largest sprocket. Check this alignment by looking from behind the bike; it's critical to ensure the derailleur can't push the chain off the sprocket and into the spokes. That could result in a bent derailleur or hanger if you're lucky or broken spokes and a good case of road rash if you're not. In some cases these set screws are not labeled so you'll need to look at the points where these screws press against the derailleur to determine which is the high or low screw.

Now you're ready to re-tension the gear cable. Pull the gear cable snug, not too tight, just using your fingers and tighten down the clamp bolt. Beware of over-tightening this bolt, it's easy to strip threads or break off the bolt head.

After you're comfortable that the adjustments for the smallest and largest sprockets are set then shift up one gear from the smallest sprocket and turn the pedals. You should hear one clear click from the index shifter followed by a clean gear change onto the next sprocket. If not, then the cable tension needs adjusting. If it won't shift up onto the adjacent larger sprocket or shifts slowly the cable needs to be tighter. Twist the barrel or index adjuster located on either end of the gear cable counter-clockwise in quarter turn increments until the chain seats smoothly and quietly into the next gear. If the chain shifts but wants to skip onto the next larger sprocket, twist the barrel adjuster clockwise in quarter turn increments to improve the alignment. If you have a problem shifting down to a smaller sprocket, loosen the cable a bit by turning the adjuster clockwise. Should you still have difficulty with shifting then release the cable at the clamp bolt again and tighten it just a bit if there's a problem shifting up into a larger sprocket and loosen it if it won't shift down into a smaller sprocket. FYI, many bikes have two barrel adjusters, the one next to the shifter will be handy for a quick adjustment while riding.

Now you can cleanly shift up and down, 1 gear at a time; a nice clear click and shift. If you still hear a slight sound or the shift seems to be too slow then it's time to adjust the “B-tension” screw, a solo screw on many derailleurs that lets you fine tune the angle of the cage so that it clears all of the sprockets. The goal is to have a similar tension on the upper “b” and lower “a” springs that take up chain slack as you shift. Loosening this screw will bring the upper jockey pulley in closer to the sprockets for better shifting. Be sure to check this alignment in the bike's lowest gear (the smallest front chainring and the largest sprocket in the rear set); if this screw is too loose, the pulley could rub on the largest sprocket.

Note that Campanolo rear derailleurs have an “A-tension” screw instead of a “B” screw that adjusts the lower spring instead. In this case, tighten the “A” screw to achieve the proper tension and alignment of the upper jockey roller under the sprockets.

Don't forget to lube the chain after all the adjustments are done and do a test ride. You may find that there's just a little tweaking needing to be done once the weight of the rider is on the bike so take your tools along.

Remember to examine the chain and sprockets, too. A dry or rusty chain can cause poor shifting as can an older or heavily used chain that has stretched. A worn chain or set of sprockets with worn teeth may cause skipping as you pedal, so you might need to replace one or both. In general if you replace the cassette or freewheel, it's a good idea to also install a new chain. Then the two will wear together with better shifting and longer life for both components. Check for a stiff or damaged link if the chain has a regular jump or sticky point as you pedal. Watch as the chain feeds through the pulleys as you backpedal and the problem link should be easy to spot. This is simple to fix with an inexpensive chain tool that spreads the outer plates of the tight link just a bit so they will flex more easily at the pins that connect the links. If you notice this while your on the road without a full set of tools, find the tight link and gently twist the links around it from side to side which should free up the sticky link.

This video by Sweetsbench summarizes these basic derailleur adjustments:

What causes the derailleur to go out of adjustment? With a new bike or cable, there's some “stretch” or slack of the shifter cable that develops over time resulting in poor shifting. With an older or dry, oxidized cable, friction inside the cable housing can make each shift feel difficult so the cable may need lubrication or replacement. Also check for a frayed cable or broken housing or a broken jockey roller; these will need to be replaced. An unfortunate impact could smack the derailleur hard enough to bend it or the derailleur mount (the hanger), possibly even bending a rear dropout on the frame in towards the rear wheel. More often it's the hanger made with a lighter material that's the culprit and bends. No amount of adjustments will help unless the derailleur is hanging straight.

Take a quick look from behind the bike at wheel level to check the vertical alignment of the two pulleys or jockey rollers inside the cage to verify that the derailleur is hanging straight. The lower pulley should be directly underneath the upper one positioned just below the sprockets or the chain will not track properly. If this checks out, then you're ready to begin the adjustments. (Note: some derailleurs with a longer cage designed to accommodate a wide gear range may have the lower roller offset outwards just a bit.)

If the derailleur or hanger is bent, a bike shop mechanic will use a special derailleur alignment tool to straighten it. In the case of a bent hanger that is not part of the derailleur but bolted onto the frame, it may be better and less expensive to replace it rather than bend it. However, at home or on the road you can readily remove the derailleur and carefully bend the tab on the hanger with a set of pliers or an adjustable wrench for a temporary fix. Don't try to straighten the derailleur by bending the pulley cage; you're more likely to damage the cage or misalign the pulleys.

Begin the derailleur adjustment by loosening the gear cable at the derailleur clamp bolt, then reset the barrel adjusters at the derailleur and/or shifter body by screwing them all the way down (clockwise), then screw them out (counter-clockwise) one full turn. This gives you room to do fine adjustments of the cable tension when needed. Leave the cable loose while you adjust the limiter screws for a more accurate adjustment.

Shift into the highest gear (the smallest sprocket) by turning the cranks. If the chain doesn't seat on this sprocket smoothly or looks like it will jump off into the gap between the frame and the sprocket, then you need to adjust the set screws. Look for the pair of small screws on the derailleur body and find the one marked with an “H.” Turn this screw clockwise to limit the motion of the derailleur outwards if the chain tries to jump into the frame and counter-clockwise if the chain won't land firmly on the outer sprocket. The upper pulley or jockey roller should now be directly underneath the smallest sprocket when you check it from behind.

Next, press in on the derailleur to help shift into the lowest gear, your largest sprocket. If the chain won't shift onto that sprocket or tries to shift into the spokes adjust the other set screw marked “L” so that the upper pulley is centered directly below the largest sprocket. Check this alignment by looking from behind the bike; it's critical to ensure the derailleur can't push the chain off the sprocket and into the spokes. That could result in a bent derailleur or hanger if you're lucky or broken spokes and a good case of road rash if you're not. In some cases these set screws are not labeled so you'll need to look at the points where these screws press against the derailleur to determine which is the high or low screw.

Now you're ready to re-tension the gear cable. Pull the gear cable snug, not too tight, just using your fingers and tighten down the clamp bolt. Beware of over-tightening this bolt, it's easy to strip threads or break off the bolt head.

After you're comfortable that the adjustments for the smallest and largest sprockets are set then shift up one gear from the smallest sprocket and turn the pedals. You should hear one clear click from the index shifter followed by a clean gear change onto the next sprocket. If not, then the cable tension needs adjusting. If it won't shift up onto the adjacent larger sprocket or shifts slowly the cable needs to be tighter. Twist the barrel or index adjuster located on either end of the gear cable counter-clockwise in quarter turn increments until the chain seats smoothly and quietly into the next gear. If the chain shifts but wants to skip onto the next larger sprocket, twist the barrel adjuster clockwise in quarter turn increments to improve the alignment. If you have a problem shifting down to a smaller sprocket, loosen the cable a bit by turning the adjuster clockwise. Should you still have difficulty with shifting then release the cable at the clamp bolt again and tighten it just a bit if there's a problem shifting up into a larger sprocket and loosen it if it won't shift down into a smaller sprocket. FYI, many bikes have two barrel adjusters, the one next to the shifter will be handy for a quick adjustment while riding.

Now you can cleanly shift up and down, 1 gear at a time; a nice clear click and shift. If you still hear a slight sound or the shift seems to be too slow then it's time to adjust the “B-tension” screw, a solo screw on many derailleurs that lets you fine tune the angle of the cage so that it clears all of the sprockets. The goal is to have a similar tension on the upper “b” and lower “a” springs that take up chain slack as you shift. Loosening this screw will bring the upper jockey pulley in closer to the sprockets for better shifting. Be sure to check this alignment in the bike's lowest gear (the smallest front chainring and the largest sprocket in the rear set); if this screw is too loose, the pulley could rub on the largest sprocket.

Note that Campanolo rear derailleurs have an “A-tension” screw instead of a “B” screw that adjusts the lower spring instead. In this case, tighten the “A” screw to achieve the proper tension and alignment of the upper jockey roller under the sprockets.

Don't forget to lube the chain after all the adjustments are done and do a test ride. You may find that there's just a little tweaking needing to be done once the weight of the rider is on the bike so take your tools along.

Remember to examine the chain and sprockets, too. A dry or rusty chain can cause poor shifting as can an older or heavily used chain that has stretched. A worn chain or set of sprockets with worn teeth may cause skipping as you pedal, so you might need to replace one or both. In general if you replace the cassette or freewheel, it's a good idea to also install a new chain. Then the two will wear together with better shifting and longer life for both components. Check for a stiff or damaged link if the chain has a regular jump or sticky point as you pedal. Watch as the chain feeds through the pulleys as you backpedal and the problem link should be easy to spot. This is simple to fix with an inexpensive chain tool that spreads the outer plates of the tight link just a bit so they will flex more easily at the pins that connect the links. If you notice this while your on the road without a full set of tools, find the tight link and gently twist the links around it from side to side which should free up the sticky link.

This video by Sweetsbench summarizes these basic derailleur adjustments:

Last edited: