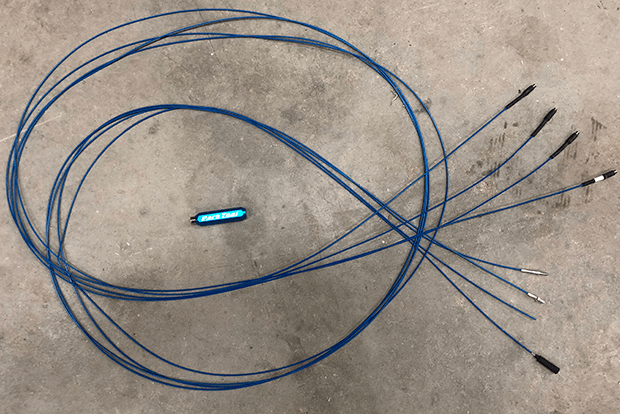

So, I replaced all the brake line hoses, shifter cable, and housing with all OEM items (Jagwire - Universal 1x Pro Shift Kit |for Road, MTN, and Gravel Bike | SRAM and Shimano Shifter Compatible, Polished Stainless Cable), (Shimano BH90-SB 2000mm Disc Brake Hose Kit Black for XT M8000/785 and SLX for the rear. 1000mm for the front.). Of course, this is to accommodate the SATORI Heads up 4 Alloy Riser Adapter Fork Bike Stem 28.6x117mm Extension. With the Kinekt Suspension Stem, I needed the extra length as things were maximum stretched out, and unsafe. I tackled the job with a bit of hesitation at first, simply because I could not accept the professed capabilities of 2 different local bike shops who acted like "yea, we've routed cables in the frames of e-bikes before"....not! They even gave me the wrong part numbers.

So I researched the daylights out of all things needed and got the parts and bit the bullet. It was a challenge, some tricks, things you probably would know if you were a

Specialized mechanic, but nonetheless, I feel 100% confident that I can handle my own repairs fully without having the stress of 14-year-old kids or other unqualified bike shop mechanics. I trust nobody. No need to share the war stories, but those who know where I'm coming from will clearly "get it".

Yes, I had to buy that Park Tool IR-1.2 Internal Cable Routing Kit for Bicycle Frames and it is pretty slick!

So, with 3500 miles in 11 months and ready for my 3rd chain, I figured heck, might as well, why not....so new cassette, new rotors, new brake pads, and it's just like new....except me, my skills are not what they should be for adjusting the derailleur, so I had the "expert/seasoned" LBS dude do it, 1,000 % flawless job.

So at the end of the day, I did maybe 50 miles and it's much more enjoyable to ride, rides and shift well, no issues from that project (which, BTW took me 8 hours, a went real, real sloooow and took my time.

The cables run under the motor cover and in the battery cavity under a plastic "raceway" and out the front headtube. The hardest cable housing was running through the frame on the side of the motor and a quick in and out where it exits at the derailleur.

Oh, and just as a side note I finally got a human at Rider Care, expressed my concerns about the level of competency of the LBS's mechanics, and was told, "Each and every shop is a private entity for which we have no control over and blah, blah, blah...", ya know just like the Ford Focus Electric I had to sue Ford for (Lemon Law), the Ford Mother Ship said basically the same words, we have no control of each dealer, but if we get complaints, they may have an effect on them carrying our franchise/product.....

I have zero issues paying a LBS QUALIFIED tech a few hundred dollars if I know he could be 100% trusted to have the same work ethic as I do. But other than the referral of previous relationships, how will one know?

So, I'm happy, I did it myself, it's great, I love it and I think I good for another 3-5,000 miles.

Oh, one last note. 2 weeks ago I took the bike to the selling LBS to check the motor bolts for proper torque.....after his efforts, things were slightly better but still came back from time to time. So, when running the derailleur cable housing I had to loosen the motor bolts (which he said he 'greased' NOT! all he do was super tighten them, nada, no grease.

So I put that grease that is used on carbon fiber posts so they don't slip, BINGO, all noises are non-existent.

Quick question...bleeding the brakes, that miserable hose they give you in the kit that falls off the bleed screw and the syringe after a few uses......ANYONE KNOW what exact size that will stay put or another solution?

Here are a few photos.