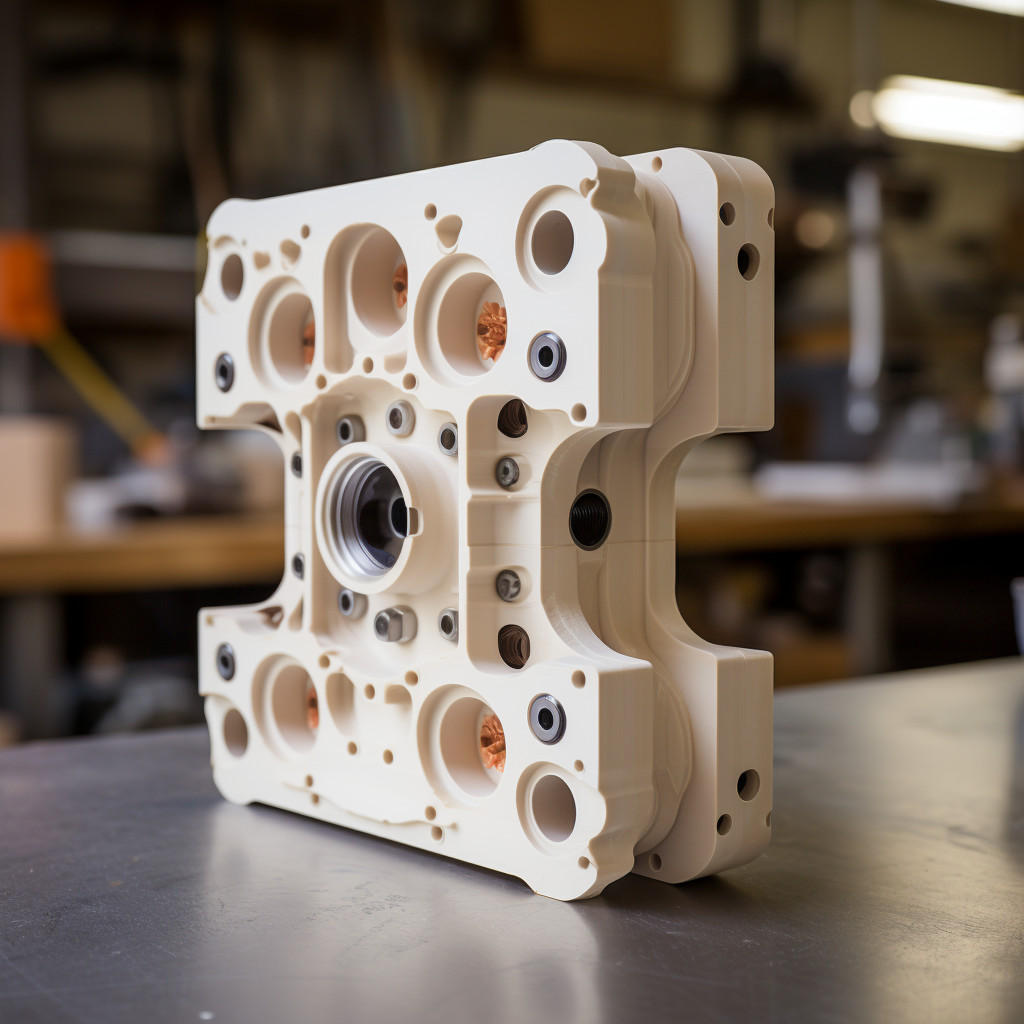

This is the gear size that is in the G062-1000W.

It is a little thinner but it would work. Any gears to this specification will fit.

The Modulus is 1.25 and 36 teeth.

Could defiantly make this one work.

Material: C45. Milled teeth. Tooth quality 8d25 DIN 3967. Pressure angle 20°.

maedlernorthamerica.com

Looks like were gonna be going steel though.

Unless we go here but it won't be cheap unless a bunch of us ordered them.

Custom machined PEEK products | Get a quote | Supplier & vendor for parts & components | Applications, properties, & material data.

www.piedmontcmg.com

This is the Design Criteria For the Gears.

Well we have all the data we need to manufacture a really really good gear.

I'm thinking to use this Peek Material. It's Carbon Filled.

HONYPLAS PEEK tube is a semi-crystalline,show high stiffness and hardness. and an unique high tensile strength and fatiue strength,Resistant to high-engery radiation.High abrasion and wear resistant.Good electrical insulator even at high voltages,and is characterised mainly by its very good mechanical properties and exceptional dimensional stability even continous operation at high temperatures of up to 250°C.

Item: Carbon Fiber Filled

PEEK tube CA30 PEEK

Material: PEEK, PEEK+GF, PEEK+CF, PEEK HPV

Working temperature: 260-340 degree

Color: natural, black, yellow rice

Density: 1.40g/cm3 (the actual density is subjected to the final confirm)

Tolerence: +/-0.1-0.5mm, according to different sizes

Sizes available:

Diameter: 5,6,8,10,12,15,16,18,20,25,30,40,50,75,80,90,100,120,140,150mm; special sizes can be cut as requirement.

Length: standard-1m, or some short pieces

Properties:

Working temperature: 260-340 centigrade

Flame retadant: V-0

Good toughness and rigidity,

high hardness,excellent wear resistance.

good insulation, anti-ydrolysis,radiation-resistant

It's gonna be a little work to machine them but its really the best way.