Gionnirocket

Well-Known Unidentified Member

- Region

- USA

- City

- Y. O.

Wow... the more you look into these bikes, the better they get!

There was a white pasty substance that looked like permatex teflon paste used to seal water pipe threads between the controller and mount,.. Another fella said it was used to transfer heat to the frame from controller.

Ah. That is what it was then. Thanks for the info! I wasn't aware there was such a thing. Looking at the thermal conductivity of that stuff is like .671-4.8 w/m-k. Copper is 385-397 w/m-k and aluminum is 205!It's most likely heatsink plaster,..

View attachment 199736

It's specifically designed to conduct heat but Not electricity.

Most things that transfer heat also conduct electricity.

The plaster is safe to use to remove heat without shorting out any wires or conductors.

They also have heat transfer tape and different colored heat transfer "grease".

I also ordered some silicone heatsink glue to glue things in place, but I was sent the same type of paste. It doesn't cure and harden up like I was expecting.

Ah. That is what it was then. Thanks for the info! I wasn't aware there was such a thing. Looking at the thermal conductivity of that stuff is like .671-4.8 w/m-k. Copper is 385-397 w/m-k and aluminum is 205!

Interesting, thanks for the info. Hadn't thought to google it. Just finished putting it all back together, the more times I do this the better I am at getting the wiring routed better and in the right places. I did use the copper paste, don't know if it is going to make a whole lot of difference, the bottom of the controller is anodized and it wasn't coming off with the effort I put in, but the inside of the box was bare aluminum.

I'm the controller on my bike and I'm often pot'd.... does that count?

Wonder how the balancer works for charging or is it just for depletion of the batteries.

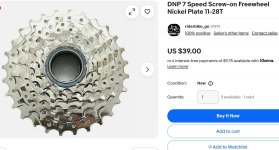

I'm not positive but I think that's a freewheel not a cassetteLooking for a tool to pull this cassette off. Think this is the ring that needs to be removed. It is 6 prong, can't find any. About 1.3" i.d. at the inner prong cutout.

View attachment 200406

The stock 203 brakes are pretty good. I installed 220 disc on the front and gonna put same on rear. Fixing some of the Chinese engineering at the moment. Took a file to the axle, it is soft, don’t think there is any hardening done to it. The threads into the frame are disappointing.I worked on a bike like this last month. Stopping distance from 20 mph was 120 feet. It was 98.4 pounds with mechanical brakes. One local shop quoted $740 to install four piston hydro. I did it for a lot less and that was the braking fix.