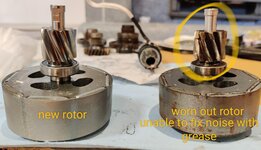

You should also clean the rotor gear as much as you can, and look if it seems to be worn out or not. It wears out from the middle section where other gear is touching it. So you should be able to very clearly see if it has started to wear out or not.

I have opened many of these motors that have been too noisy. If gears are only a little bit worn out, then greasing will help. But if there is too much damage, then greasing doesn't help anymore. Those motors that I have opened up, it has always been the rotor gear that has had the most damage, and secondly the gear that is touching rotor (third gear). If either one of these gears is clearly worn out, then I will always change both at the same time. By only changing the "third gear" + greasing it is possible to get motor to be silent. But, if worn out rotor is not changed, it will eat up the third gear faster. If your rotor is not worn out, you are lucky.

Changing the rotor gear can be tricky, and because I don't have tools to separate rotor gear from rotor, I always change whole rotor with gear. When changing the rotor or rotor gear, you should also buy calibration display to get motor running again. (If position of magnet at the end of rotor changes in relation to rotor itself, the motor will need a calibration with C961 calibration display. Calibration can be done manually also, but is painful and will need many trial and errors before made succesfully. Rotor is changed by opening the other cheek of the motor (3 screws). Pulling out the rotor needs some fiddling, because magnets keep it very tightly on its position. And when installing new rotor one should always check that rotor doesn't have any metallic parts sticking out. I have had a small metallic plate stick out of the rotor, and when rotor was rotating inside motor, that metallic part touched stator and caused horrific noise and caused electricity to go from rotor to stator via that small metallic piece (after opening motor again there were a small area that was "burnt" because of that. But motor was ok after I removed that broken piece, no damage to motor because I fixed it immediately after noticing.

So for me the minimum is greasing the motor, but if there is visible damage, then I will always change at least 2 gears (well, 1 gear and rotor). And when motor has been opened, it is good practise to also check if that small pawled clutch behind biggest gear is ok. Pawls shoud move with ease and have decent amount of spring tension in all of them. That is a cheap part and if it breaks up, you notice it by not being able to pedal the bike (with throttle it will still move).

Oh, if you later want to change the rotor too, it can be removed and installed back while motor is installed to your bike already. Actually it is easier to pull out while motor being on bike rather than motor being on you table.. And you better be prepared with C961 IF you want to do this.

I focused here to gears and greasing, but just to mention, if there is metallic pieces inside the motor, it is always possible that some bearing has broken. They should all rotate easily without any grinding sensation when rotated with hands. For me, any noise has always been caused by gears, but broken bearing is not rare either with other people I have talked to.