blozza77

New Member

- Region

- United Kingdom

I took my bike into a Orbea dealer today, they are going to sort it out for me. They suggested this is not a selfservice job because the freehub is part of the motor housing/cover and appears to be a sealed unit with no through axle, bit of a bummer becasue I've only had the bike 8 months and was enjoying riding it on trails in all sorts of conditions, might have to dial that back a bit if I can't get in there and clean/maintain it myself.I’m still waiting to hear , really gutted as have been told not to ride the bike, also a D31. I’m not sold on the fact that the whole motor has to be replaced if the freehub has gone. I also been riding in all conditions over the last few months. If there’s anyone out there with more information about replacing the freehub, I and many others would be really appreciative your help.

I can't find anything online of how to take apart the x35, perhaps there will be as they get older.

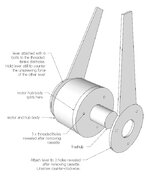

I did find a picture (below) of a Q128C motor cover which has a built in freehub, I suspect its something similar.

I'll report back once its been repaired.