BMWzenRider

Active Member

Tech Warning: This post has numbers and spreadsheets involved!

I am going to be changing the primary gear reduction of my Gates belt drive, and need to know if my proposed changes will require any changes to the programming of the Bosch software/firmware?

I bought the standard Class-1 version of the 2021 Homage to get the Performance Line CX motor with the excellent adaptive eMTB mode which works spectacularly well with my bad knees.

Additionally, I went with the Rohloff gear hub option with Gates Carbon Drive belt for a wider gear range and less maintenance.

First, let me say, that overall I am still in love with this bike!

The suspension, the assist, the range, and the ease of getting on/off are all worlds ahead of any other model I have owned or tried.

But no bike designed to fit the widest range of owners is going to be perfect in every way.

And I would like to change mine to be a bit more perfect for ME!

For instance, I have swapped out the optional 70mm dropper post for a 100mm drop, and now I can get both feet flat on the ground at a stop without having to slide off of the saddle!!!

---------------------

Crank Length:

---------------------

I have a fairly short inseam for my height, and the aforementioned bad knees, so I have already installed shorter 160mm cranks to help keep my knees happy.

So far I am very much enjoying that change.

The shorter cranks allow me to maintain my spin much more comfortably from the smaller circle the pedals rotate around, and noticeably reduces the total flexure of my knees and hips, which also helps.

The shorter crank arms also allow me to pedal while leaned farther over into a turn/curve without striking the ground, which is also a good thing.

I also have an even shorter set of 155mm cranks which I intend to try as well to see how they feel.

My understanding is that there is a setting in the dealer software which can be toggled for different crank lengths.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

- Does anybody know if there are pre-sets for 160mm or 155mm cranks?

- How does this setting affect the assist level? (would I get more or less assist from the motor for a given crank torque with the shorter cranks programed in?)

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------

The Current Issue:

---------------------

To provide less strain on my knees, I try to maintain a pedal cadence of 80-90rpm.

What this means in practice with the stock primary belt drive gearing on the Rohloff equipped Homage is that I am spinning out of my Assistance Cut-Off Limit of 20mph in 10th gear.

This leaves the upper 4 gears of the Rohloff hub basically useless to me.

I am a recreational rider, and do not intent to be pedaling furiously downhill to maximize my top speed, and I will never again have the leg strength to push a bicycle past 20mph without power assist, even with a stiff tailwind.

This area is fairly hilly, not mountainous, but the Kettle Moraine Forest around here was formed by the glaciers pushing up mounds of dirt, and deep holes where buried chunks of ice melted. It results in frequent changes in slope, some quite steep.

Even with Turbo mode and 340% assist, I have rather often found myself wanting a shorter low gear, and am never shifting above 10th, because I am coasting to recover on the descents.

Which brought up the idea of changing the cogs on the belt drive to shift the overall gear range lower for my needs.

------------------------------------------------------------------------------------

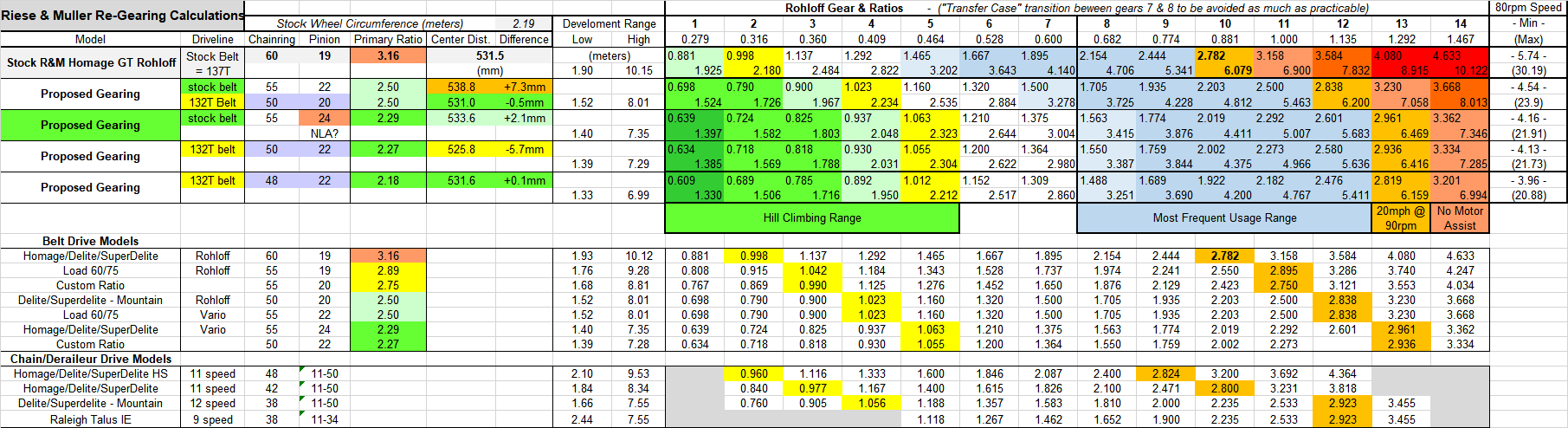

Below is the spreadsheet that I cooked up to help with the decision making.

------------------------------------------------------------------------------------

The upper block shows the current stock Homage/Rohloff/Gates gearing and the resulting gear rations and development for each gear of the Rohloff hub.

Just below the stock bicycle setup numbers are the alternate gearing ratios I am looking at.

The upper left number in the resulting gearing cells is the overall gear ratio for the belt & hub gearing, and the lower right number is the development per pedal revolution in meters.

The column at the far right in the upper block shows the speed that each gearing combination would deliver in both 1st & 14th gear when pedaling at 80rpm.

For each alternate gearing I have shown the difference in the theoretical center-line distance between the pulleys according to the Gates online calculators, and the difference from the stock setup.

I have measured that the rear dropouts have approximately +5mm to -8mm of adjustment space available.

The lower blocks in the spreadsheet show various gearing combinations for other R&M Full-Suspension models, including all three of the primary drive options (Rohloff, Nuvinci, & chain), a few custom ratios using cogs R&M uses across the modesls, as well as my previous E-bike's drivetrain thrown in for me to be able to compare them against another bike that I am familiar with.

The color-coding of the developed gearing cells to the right side is as follows:

- Green = Granny gears (less than 1 wheel revolution for each turn at the cranks)

- Yellow = Direct-Drive (approx.) 1:1 wheel to crank revolution

- Blue = most frequently used gears in level or slightly rolling terrain

- Orange = 20mph motor assist cut-off when pedaling at 80-90rpm

- Red & Pink = No motor assist at normal pedal cadence.

One thing that becomes very obvious when looking at the chain drive versions is that R&M DOES change the gearing on those models between the HS and standard Class-1 bikes, and goes even lower for the "Mountain" versions by changing the size of the chainrings for each.

So, with all the other belt drive gear ratios that R&M is currently using across the various Full-Suspension models, why do they not offer different gear ratios for the HS vs. Class-1 versions???

My aim is to fix that oversight.

And it is clear that there are several options for doing so with parts that R&M is already using on other models.

-----------------------

Hub Considerations:

-----------------------

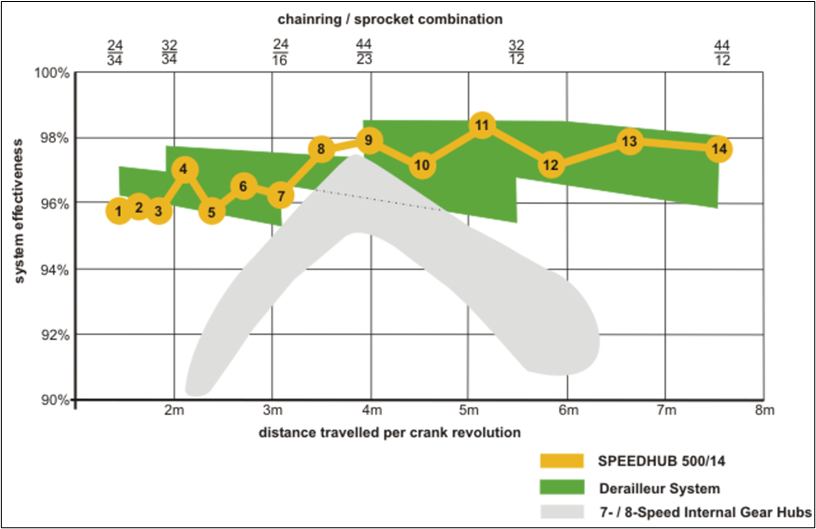

Another factor to take into account when using the Rohloff hub is that it is more efficient in the upper 7 gears,

AND, that the shift between 7th & 8th gear is a bit more clunky and takes longer than other transitions because the Rohloff is basically a 7-speed hub with a 2-speed transfer case.

The transfer case under-drives the seven gears for the low-range 1-thru-7 gears, which causes them to spin faster.

That is what causes the additional losses in the hub in the lower range gears.

To change between 7th-to-8th (or 8th-to-7th) the hub does two separate shift operations in sequence, going from low-to-high on the transfer gears, as well as 7th-to-1st in the main geartrain.

You can see the definitive change of the internal hub efficiency in this graph from the Rohloff website.

SO, ideally, I want to also pick a primary gear reduction which lets me stay in the upper range of the hub as much as possible.

Since I have already proven to myself that pretty much any final gearing above 2.80-2.90 is not usable for my physical condition,

Adding in the hub considerations puts me looking most intently at the 2.29 or 2.27 primary belt drive ratios most closely,

My preferred solution is to go with the 55/24 combination which will allow me to use the stock belt length, since I already bought a spare to get me home if disaster strikes.

And if I do decide that is too low, I can swap the 24T rear cog for a 22T while still using the same belts.

(and keeping the sprockets as large as possible reduces hysteresis losses from less belt bending)

Yes, I know that the 24T Gates sprocket for Rohloff was only made for the older threaded fitting and is technically discontinued, but I do have a source for one and the required threaded adapter ring.

---------------------

My question are:

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

- Does the programing for the Bosch system need to be changed if the overall gear range of the drive belt/hub combination is changed?

- IF SO, can the dealer do that themselves in their accessible settings, or does it need to come down from higher up?

- IF it needs to come from higher up, is that from Bosch, or R&M?

- AND, if it needs to come from higher up, is it better for me to contact those people, or to leave it to the LBS?

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Thanks in advance for any/all who can help me get this sorted out.

Karl

I am going to be changing the primary gear reduction of my Gates belt drive, and need to know if my proposed changes will require any changes to the programming of the Bosch software/firmware?

I bought the standard Class-1 version of the 2021 Homage to get the Performance Line CX motor with the excellent adaptive eMTB mode which works spectacularly well with my bad knees.

Additionally, I went with the Rohloff gear hub option with Gates Carbon Drive belt for a wider gear range and less maintenance.

First, let me say, that overall I am still in love with this bike!

The suspension, the assist, the range, and the ease of getting on/off are all worlds ahead of any other model I have owned or tried.

But no bike designed to fit the widest range of owners is going to be perfect in every way.

And I would like to change mine to be a bit more perfect for ME!

For instance, I have swapped out the optional 70mm dropper post for a 100mm drop, and now I can get both feet flat on the ground at a stop without having to slide off of the saddle!!!

---------------------

Crank Length:

---------------------

I have a fairly short inseam for my height, and the aforementioned bad knees, so I have already installed shorter 160mm cranks to help keep my knees happy.

So far I am very much enjoying that change.

The shorter cranks allow me to maintain my spin much more comfortably from the smaller circle the pedals rotate around, and noticeably reduces the total flexure of my knees and hips, which also helps.

The shorter crank arms also allow me to pedal while leaned farther over into a turn/curve without striking the ground, which is also a good thing.

I also have an even shorter set of 155mm cranks which I intend to try as well to see how they feel.

My understanding is that there is a setting in the dealer software which can be toggled for different crank lengths.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

- Does anybody know if there are pre-sets for 160mm or 155mm cranks?

- How does this setting affect the assist level? (would I get more or less assist from the motor for a given crank torque with the shorter cranks programed in?)

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------

The Current Issue:

---------------------

To provide less strain on my knees, I try to maintain a pedal cadence of 80-90rpm.

What this means in practice with the stock primary belt drive gearing on the Rohloff equipped Homage is that I am spinning out of my Assistance Cut-Off Limit of 20mph in 10th gear.

This leaves the upper 4 gears of the Rohloff hub basically useless to me.

I am a recreational rider, and do not intent to be pedaling furiously downhill to maximize my top speed, and I will never again have the leg strength to push a bicycle past 20mph without power assist, even with a stiff tailwind.

This area is fairly hilly, not mountainous, but the Kettle Moraine Forest around here was formed by the glaciers pushing up mounds of dirt, and deep holes where buried chunks of ice melted. It results in frequent changes in slope, some quite steep.

Even with Turbo mode and 340% assist, I have rather often found myself wanting a shorter low gear, and am never shifting above 10th, because I am coasting to recover on the descents.

Which brought up the idea of changing the cogs on the belt drive to shift the overall gear range lower for my needs.

------------------------------------------------------------------------------------

Below is the spreadsheet that I cooked up to help with the decision making.

------------------------------------------------------------------------------------

The upper block shows the current stock Homage/Rohloff/Gates gearing and the resulting gear rations and development for each gear of the Rohloff hub.

Just below the stock bicycle setup numbers are the alternate gearing ratios I am looking at.

The upper left number in the resulting gearing cells is the overall gear ratio for the belt & hub gearing, and the lower right number is the development per pedal revolution in meters.

The column at the far right in the upper block shows the speed that each gearing combination would deliver in both 1st & 14th gear when pedaling at 80rpm.

For each alternate gearing I have shown the difference in the theoretical center-line distance between the pulleys according to the Gates online calculators, and the difference from the stock setup.

I have measured that the rear dropouts have approximately +5mm to -8mm of adjustment space available.

The lower blocks in the spreadsheet show various gearing combinations for other R&M Full-Suspension models, including all three of the primary drive options (Rohloff, Nuvinci, & chain), a few custom ratios using cogs R&M uses across the modesls, as well as my previous E-bike's drivetrain thrown in for me to be able to compare them against another bike that I am familiar with.

The color-coding of the developed gearing cells to the right side is as follows:

- Green = Granny gears (less than 1 wheel revolution for each turn at the cranks)

- Yellow = Direct-Drive (approx.) 1:1 wheel to crank revolution

- Blue = most frequently used gears in level or slightly rolling terrain

- Orange = 20mph motor assist cut-off when pedaling at 80-90rpm

- Red & Pink = No motor assist at normal pedal cadence.

One thing that becomes very obvious when looking at the chain drive versions is that R&M DOES change the gearing on those models between the HS and standard Class-1 bikes, and goes even lower for the "Mountain" versions by changing the size of the chainrings for each.

So, with all the other belt drive gear ratios that R&M is currently using across the various Full-Suspension models, why do they not offer different gear ratios for the HS vs. Class-1 versions???

My aim is to fix that oversight.

And it is clear that there are several options for doing so with parts that R&M is already using on other models.

-----------------------

Hub Considerations:

-----------------------

Another factor to take into account when using the Rohloff hub is that it is more efficient in the upper 7 gears,

AND, that the shift between 7th & 8th gear is a bit more clunky and takes longer than other transitions because the Rohloff is basically a 7-speed hub with a 2-speed transfer case.

The transfer case under-drives the seven gears for the low-range 1-thru-7 gears, which causes them to spin faster.

That is what causes the additional losses in the hub in the lower range gears.

To change between 7th-to-8th (or 8th-to-7th) the hub does two separate shift operations in sequence, going from low-to-high on the transfer gears, as well as 7th-to-1st in the main geartrain.

You can see the definitive change of the internal hub efficiency in this graph from the Rohloff website.

SO, ideally, I want to also pick a primary gear reduction which lets me stay in the upper range of the hub as much as possible.

Since I have already proven to myself that pretty much any final gearing above 2.80-2.90 is not usable for my physical condition,

Adding in the hub considerations puts me looking most intently at the 2.29 or 2.27 primary belt drive ratios most closely,

My preferred solution is to go with the 55/24 combination which will allow me to use the stock belt length, since I already bought a spare to get me home if disaster strikes.

And if I do decide that is too low, I can swap the 24T rear cog for a 22T while still using the same belts.

(and keeping the sprockets as large as possible reduces hysteresis losses from less belt bending)

Yes, I know that the 24T Gates sprocket for Rohloff was only made for the older threaded fitting and is technically discontinued, but I do have a source for one and the required threaded adapter ring.

---------------------

My question are:

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

- Does the programing for the Bosch system need to be changed if the overall gear range of the drive belt/hub combination is changed?

- IF SO, can the dealer do that themselves in their accessible settings, or does it need to come down from higher up?

- IF it needs to come from higher up, is that from Bosch, or R&M?

- AND, if it needs to come from higher up, is it better for me to contact those people, or to leave it to the LBS?

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Thanks in advance for any/all who can help me get this sorted out.

Karl

Last edited: