@TDA78 can you comment about how differences in

motor torque levels feel or seem to work? The description from the Innotrace documentation leads me to believe it's... just the initial startup torque to get things rolling/peak throttled load (not under throttle, but a temporary peak load that is throttled back by the system after some condition is met)

After going through the thread gain,

sensitivity torque interpolated between torque/cadence inputs with 0 being pure torque and 1 being pure cadence, and then actual

output is determined by torque and assist level, but assist level

does not scale the throttle value at all?

The test you did confirms this, which in my opinion isn't ideal. Another test to confirm this is the case would be to try some math to assume this is just multiplied values and set your levels to aim for the same output given each assist level.

So something like

1 - torque 36%

2 - torque 18%

3 - torque 12%

4 - torque 9%

5 - torque 7% (unless it can run a float at 7.2%)

6 - torque 6%

7 - torque 5% (unless float @ 5.1%)

8 - torque 4% (unless float @ 4.5%)

9 - torque 4%

10 - torque 3% (unless float @ 3.6%)

There's also the possibility that each level's torque amount

adds onto the previous assist level's amount, if this were the case, simple test to verify is setting level 1 at 5A and all the others at 0A, and see if assist still increases with each level. This is the situation that makes it easiest for users to determine the actual current output limit they will get from settings without having to mess with any files and potentially break stuff, and honestly the one I'm hoping for.

If display shows your current/power draw then you maybe could try setting sensitivity torque higher to make it easy to hit the max current given my the torque setting, keep all torque levels the same, then see if your current & power draw scale up with each assist level. Only issue here is motor torque setting - looks like there's 10 or 11 levels instead of a percentage like the torque setting? Might make it hard to match that value and we don't really know what conditions determine 'starting' - is it a timer after rpm>0, is it a timer once torque is exceeded, or a cutoff above a certain rpm? I skimmed through

@BarnBoy 's thread and did see there was a text file which is a little more useful, but it looks like that file doesn't actually tell us what's being done beyond just what the controller sees as those input params for the actual operations. Does anyone have any screenshots of what files you have with the X1 tool and how much you can see or is that pretty much it?

I doubt Innotrace would grant any sort of access to that code since it's a little more uncopyable than the hardware itself (if protected properly). It may be possible to do a little work in the text file that has the input params to account for any sort of scaling by assist level done by the controller but if you don't know the exact operation it's a guessing game. If by some miracle there is a little more access into the code showing how these values are used then from there it shouldn't be difficult to get it to where the assist level is only an index to different groups of settings and has no affect on how any of those values are interpreted. Ideally in my situation I think I would want to know exactly what the constant output current limit (torque setting) for each assist level is, that way it's just easier to understand the actual assist amount between each level at a glance. No taking any unseen math into account. My only concern is early on in the thread I understood (hopefully misunderstood) that Pushkar said assist level itself is what blends the torque & cadence sensor? I need to rewatch the video too maybe that clears it up a bit...

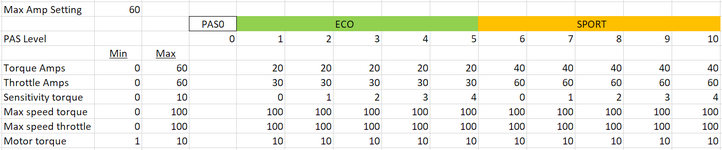

as per Innotrace doc

View attachment 124641