Another update and another delay (once again due to improvements to the design):

Hello ShareRoller Indiegogo backer:

We've made a LOT of progress since our last Update, but unfortunately have also encountered a few unanticipated delays. We'll try to share as much color as we can below so you understand both our challenges and accomplishments.

So we're nearly ready to begin assembly of the first 150 unit batch of the new ShareRoller SR4. Our team of suppliers (we have 7 different suppliers!) has been manufacturing the first batch of SR4 subcomponents since early May, and first shipments (of subcomponents) should be going out any week (we've learned that 3-4 week production estimates seem to become 4-6 weeks+ as standard practice..)

Nevertheless, here's what's ready to ship from our suppliers imminently:

- Drive Motors: We've talked a lot about these before, so you know how amazing they are - we can't wait to have hundreds of them sitting on our assembly floor!

- Custom urethane Drive Belts: We've had to go through several iterations of molding to get the fit just right on these, fortunately it's a quick turn-around so they're fully sorted.

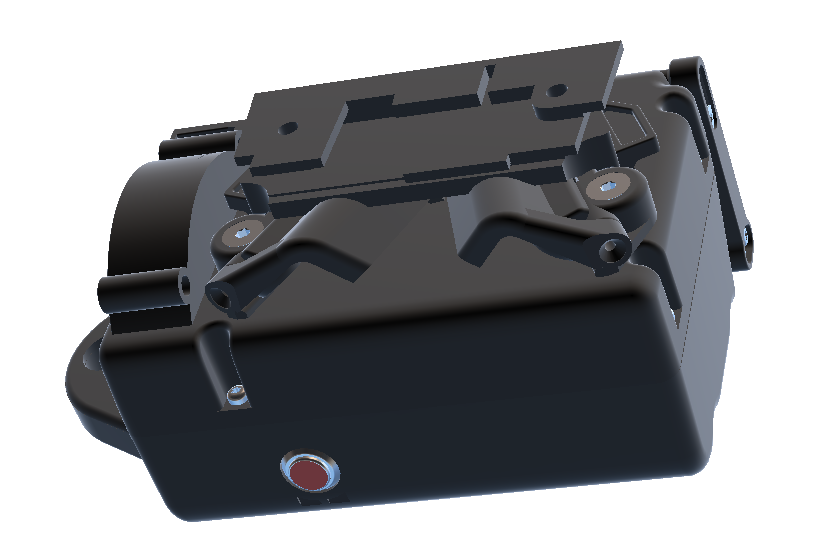

- Heatsinks: If you recall in our last email we talked about our solution to improve motor cooling, well here it is: Dual heatsink mounting plates for the motors. We had to build molds for diecast aluminum to make these cost-effectively, which takes a LONG time, but they're done now - and here's a picture of the first sample diecast parts:

- Gearmotors: We haven't talked much about these yet for IP reasons, though if you search our patent filings you'll find a reference to them... Custom ultra-small, ultra-high torque gearmotors to continually manage normal force for our Automatic Traction Control system (both under power and while braking), and to lift the motor clear off the tire when you don't need it. Our supplier has been making these for over 6 weeks now, and they're due to arrive in NYC any day.

- Wireless throttles: We've got a great custom design perfected now for our wireless custom throttles, with custom PCB production underway. Not only do they give you proportional control of both throttle and brake, but they also have secondary buttons for operating TailWind or PAS settings. Plus a rechargeable battery that seems to last days. And a really cool spring-clip mounting system with ball-joint pivot that allows you to mount the throttle almost anywhere on a bike or scooter and still find a comfortable position.

- Retracting battery cables: After our earlier quality issues were solved by upsizing the housing, our manufacturer is currently assembling our first production batch as quickly as they can. These required custom injection mold tooling, which means a 6-8 week leadtime, but they should be done in another two weeks.

Unfortunately, we have two components that are further behind schedule. Our custom PCB and our custom Battery Packs. These two components are a big piece of what makes the SR4 so special, which is a good thing given how much work they've required!

To be clear, we already had a first version production SR4 PCB several months ago and it worked well, with both the wireless throttle and phone app functionality we dreamed of. But we needed to add a few more pieces of critical functionality to it:

- Inrush current protection (aka 'Anti-Spark'): this is necessary to prolong the life of our magnetic battery connectors, especially at the higher voltages the SR4 uses.

- Onboard DC gearmotor control: we had been using a standalone board for this, but for reliability and ease of assembly it made sense to integrate it

Both of these circuits are relatively large, and since we had no more room to make the PCB any bigger, we needed to redesign it using surface-mount components (SMT) to shrink every section. This is a lot of work and has taken longer than expected, but we do expect to have production PCBs completed within 3-4 weeks, so this won't be the biggest holdup....

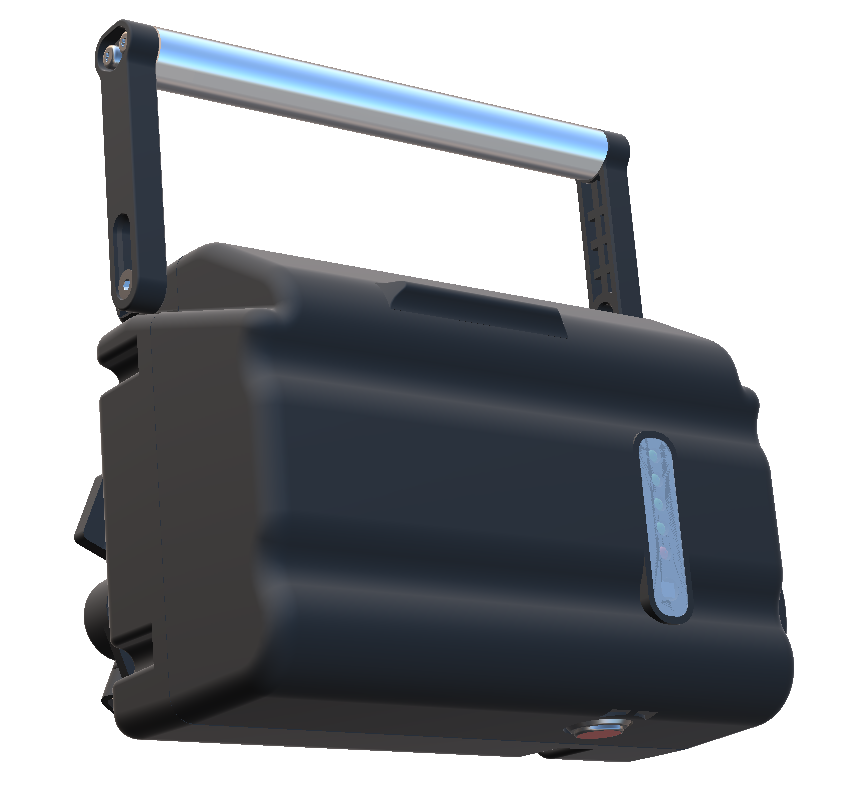

Which brings us to our custom battery packs, the most delayed of all our components: We can't begin to describe how involved the design and manufacturing process has been for these. With nearly a dozen different molded parts, a custom-designed Battery Management PCB, soft power switch, USB charge port, LED indicators, and the aforementioned retractable battery cable, this by itself is probably more complex than many hardware products in their entirety. But with ShareRoller's unique versatility and portability, an existing 'off-the-shelf' battery pack just wasn't an option.

Since we haven't shown the battery packs in detail yet, here's a teaser pic of our unique 'Multi-Mount' attachment system (on a 'Mini' pack) - believe it or not, both the mounting brackets needed for bike share use and personal bike/scooter use are contained in the folding, modular mount shown below:

The other completely unique part of ShareRoller's battery packs is our 'Versa-Handle,' which does double duty as both a carrying handle and as a locking mechanism for bikeshare use. Here's how it looks extended for transport (You can see our LED battery gauge here too, and yes that is brushed aluminum for the handle!):

We've had 'near-final' designs settled upon month-after-month for these packs, since as far back as March. And every time, it seems a new subtle tweak is needed to meet the complex demands of either our custom housing, electronics, mounting system, or unique multi-purpose handle.

The good news is that after 7 months of relentless back-and-forth CAD iterations with our supplier, we've finally resolved all design issues, signed a Molding Contract (in Chinese!) and wired a sizeable tooling deposit, so they are officially underway. Unfortunately, it will take 4 weeks to complete the molds, and another 2-3 weeks after that before packs are assembled. We also need to complete UN38.3 certification (required for air shipment), but the plan is to do that in parallel with volume assembly.

Given all of that, we don't expect to have production battery packs ready to ship before early-mid August. Fortunately, there's zero assembly required for the packs - they arrive turn-key. So we can assemble everything else in advance, and ship out complete ShareRoller SR4 boxes the moment the packs arrive.

We're deeply sorry for these continued delays and we really wish there was some way we could deliver sooner. We understand how frustrating it is to still be without ShareRoller power, especially as Summer unfolds. Unfortunately, many factors are outside our control here, so all we can do is just continue to push relentlessly to be sure the ShareRoller SR4 we finally deliver will perform beyond all expectations, and at least in hindsight make it all worth the wait.

Thank you so much for your patience and support.

Jeff Guida & The ShareRoller Team