small correction in the first sentence - 15 to 25 km (not 20)Mahle hube motor max torque is 40Nm, also they recommend to keep a 15 to 20 Km/h speed.

15Km/h using a 700 wheel ( 2,136 mts/ revolution) means 117 rpm of the rear wheel. Using a 21/34 gear cassette conbination is equivalent to keep 72 rpm pedal cadence.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Orbea Gain D50 ( User learning and experiences )

- Thread starter AntonioAlfaro

- Start date

Stefan Mikes

Gravel e-biker

- Region

- Europe

- City

- Mazovia, PL

It is precisely a torque sensor combined with the cadence sensor. The equation ngg has shown is reversed. The pedalling power is calculated as a product of rider's foot torque on the pedal and his cadence (RPM).you are correct stefan, that is measured with some devices that they sell and is placed on the cranks and rear hub

Therefore, the mid-drive motor works on this principle:

Let us assume the current Biker's Power is 100 W. The maximum assistance boost for this motor is 1.8x. The assistance level is 35% of 1.8x, or 0.63. The Motor Power would be 100 * 0.63 = 63 W. Now, if the rider's input is 50 W, the motor would respond with 31.5 W. If the rider pedals at 200 W leg power, the motor assistance would be 126 W. All these parameters are measured and are not any guess. The pedalling power depends both on the foot radial force on the pedal and on the cadence.

That is the fundamental principle of torque sensing, used in mid-drive motors.

It is not any marketing game. It is the technology. I'm sorry for you ngg your experience is limited to hub-drive motors only.

it's not reversed, but you read not carefullyIt is precisely a torque sensor combined with the cadence sensor. The equation ngg has shown is reversed. The pedalling power is calculated as a product of rider's foot torque on the pedal and his cadence (RPM).

Stefan Mikes

Gravel e-biker

- Region

- Europe

- City

- Mazovia, PL

No. It is that you do not understand.it's not reversed, but you read not carefully

Your claim the pedalling power is the motor power without resistance is simply ridiculous.

Your claim the pedalling torque is calculated from motor power is absurd.

AntonioAlfaro

Active Member

- Region

- Other

To have an idea what 40Nm torque means, lets use the ngg formula

Torque (Nm) = Power (watts) / (0.105 x Speed (RPM)

Suppose we keep 70 rpm cadence, 40 Nm is like to push the cranck ( when it is at 3pm position) with a power of 294 W. But, motor is at rear, motor is not 100% efficient, we can not always keep high cadence, road is not always flat. So 40Nm is just an indicator.

Have somebody gotten at least 250W from X35 system??? Would like to see examples.

Torque (Nm) = Power (watts) / (0.105 x Speed (RPM)

Suppose we keep 70 rpm cadence, 40 Nm is like to push the cranck ( when it is at 3pm position) with a power of 294 W. But, motor is at rear, motor is not 100% efficient, we can not always keep high cadence, road is not always flat. So 40Nm is just an indicator.

Have somebody gotten at least 250W from X35 system??? Would like to see examples.

Have somebody gotten at least 250W from X35 system??? Would like to see examples.

I got even more, but I don't know if I still have that record.

In fact, each charge of the battery goes up to 42 volts, and the motor pulls over 8 amps. So, some 330-340 watts should not be unattainable, of course in a shorter time

AntonioAlfaro

Active Member

- Region

- Other

The x35 system can deliver 250W during 1 hour. Should be interesting to test that condition.

AntonioAlfaro

Active Member

- Region

- Other

Setting and Riding with L3 at 100% means 250W of max system delivery power.

Stefan Mikes

Gravel e-biker

- Region

- Europe

- City

- Mazovia, PL

What about the human power (pedalling power), which is the same for the same cyclist on a traditional bike and on e-bike?

Let us say the cyclists inputs 150 W at cadence of 80 RPM:

Torque (Nm) = Power (watts) / (0.105 x Speed (RPM)

Torque (Nm) = 150 (W) / (0.105 * 80 rpm) = 17.9 Nm.

The same torque is exerted on pedals by the human even on an unpowered e-bike. And that's measured by the torque sensor of a mid-drive motor; then it is multiplied by the cadence (from the cadence sensor) and the constant of 0.105 to inform the controller the rider has provided 150 W of power into the cranks.

Pedalling Power = Torque at the cranks * 0.105 * Pedalling Cadence.

Who disagrees?

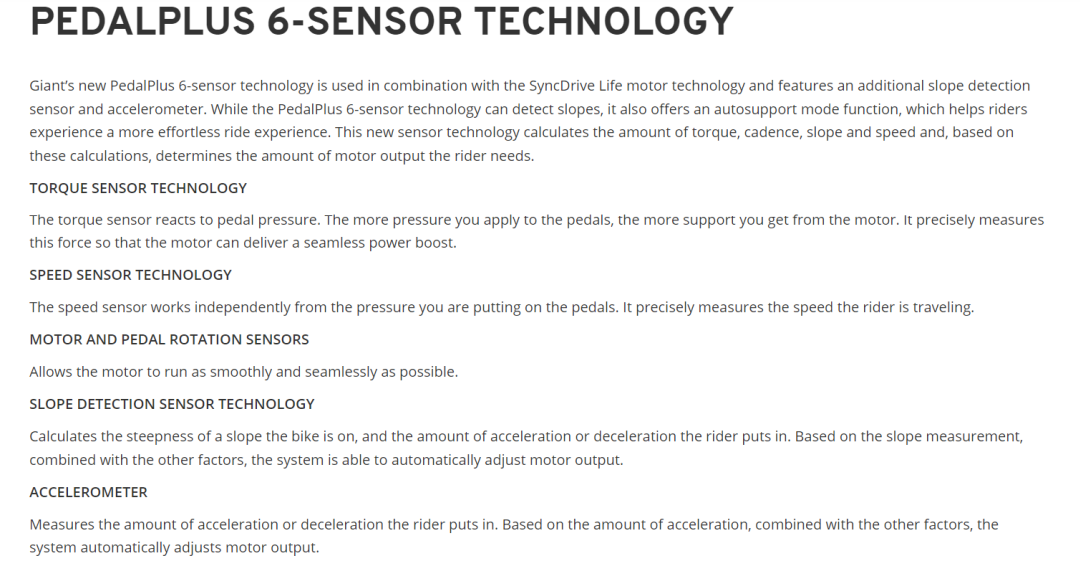

Giant uses as many as six sensors in their mid-drive e-bikes. Most of other systems are missing the slope sensor, still making them 5-sensor systems.

My question is: Is the x35 equipped with the pedalling torque sensor or not?

Let us say the cyclists inputs 150 W at cadence of 80 RPM:

Torque (Nm) = Power (watts) / (0.105 x Speed (RPM)

Torque (Nm) = 150 (W) / (0.105 * 80 rpm) = 17.9 Nm.

The same torque is exerted on pedals by the human even on an unpowered e-bike. And that's measured by the torque sensor of a mid-drive motor; then it is multiplied by the cadence (from the cadence sensor) and the constant of 0.105 to inform the controller the rider has provided 150 W of power into the cranks.

Pedalling Power = Torque at the cranks * 0.105 * Pedalling Cadence.

Who disagrees?

Giant uses as many as six sensors in their mid-drive e-bikes. Most of other systems are missing the slope sensor, still making them 5-sensor systems.

My question is: Is the x35 equipped with the pedalling torque sensor or not?

What about the human power (pedalling power), which is the same for the same cyclist on a traditional bike and on e-bike?

Let us say the cyclists inputs 150 W at cadence of 80 RPM:

Torque (Nm) = Power (watts) / (0.105 x Speed (RPM)

Torque (Nm) = 150 (W) / (0.105 * 80 rpm) = 17.9 Nm.

The same torque is exerted on pedals by the human even on an unpowered e-bike. And that's measured by the torque sensor of a mid-drive motor; then it is multiplied by the cadence (from the cadence sensor) and the constant of 0.105 to inform the controller the rider has provided 150 W of power into the cranks.

welcome to the right side

Giant uses as many as six sensors in their mid-drive e-bikes. Most of other systems are missing the slope sensor, still making them 5-sensor systems.

My question is: Is the x35 equipped with the pedalling torque sensor or not?

and what will all this do for you, when you can calculate or assume everything anyway. Everything is just a matter of a good algorithm.

AntonioAlfaro

Active Member

- Region

- Other

Answer : Negative.What about the human power (pedalling power), which is the same for the same cyclist on a traditional bike and on e-bike?

Let us say the cyclists inputs 150 W at cadence of 80 RPM:

Torque (Nm) = Power (watts) / (0.105 x Speed (RPM)

Torque (Nm) = 150 (W) / (0.105 * 80 rpm) = 17.9 Nm.

The same torque is exerted on pedals by the human even on an unpowered e-bike. And that's measured by the torque sensor of a mid-drive motor; then it is multiplied by the cadence (from the cadence sensor) and the constant of 0.105 to inform the controller the rider has provided 150 W of power into the cranks.

Pedalling Power = Torque at the cranks * 0.105 * Pedalling Cadence.

Who disagrees?

View attachment 115324

Giant uses as many as six sensors in their mid-drive e-bikes. Most of other systems are missing the slope sensor, still making them 5-sensor systems.

My question is: Is the x35 equipped with the pedalling torque sensor or not?

Stefan Mikes

Gravel e-biker

- Region

- Europe

- City

- Mazovia, PL

Not.Everything is just a matter of a good algorithm.

A torque/cadence system (a mid-drive motor) can measure the rider's leg input (power) and produce assistance proportional to that input. No algorithm can guess the missing information for the hub-drive system, which is the torque applied by the rider's feet.

If you downshift to the low gear on your Vibe and spin at cadence 80 rpm, x35 motor might guess you want to ride fast. Go to the top gear and pedal at 40 rpm. You can mash pedals as strongly as you want but x35 won't guess you are actually delivering the same power as before.

Torque = 18 Nm, cadence = 80 rpm, pedalling power = 151.2 W

Torque = 36 Nm, cadence = 40 rpm, pedalling power = 151.2 W

Torque = 18 Nm, cadence = 80 rpm, pedalling power = 151.2 W

Torque = 36 Nm, cadence = 40 rpm, pedalling power = 151.2 W

I think Mahle is optimized at 70 RPM. That has been written before. With this cadence, it is easiest to ride a bike.

Stefan Mikes

Gravel e-biker

- Region

- Europe

- City

- Mazovia, PL

The point is, a mid-drive motor will deliver the required motor power anytime, and at any RPM. The cost of decreased motor efficiency is the increased power draw from the battery.I think Mahle is optimized at 70 RPM. That has been written before. With this cadence, it is easiest to ride a bike.

I just want to re-iterate: the x35 motor is the right tool for its application. There are many applications.

ok, but some RPMs don't make sense, like 40. But let it go and pay attention to the message from @r1roman. The picture clearly shows that torque is expressed. And we are trying to find out how they come about.The point is, a mid-drive motor will deliver the required motor power anytime, and at any RPM. The cost of decreased motor efficiency is the increased power draw from the battery.

I just want to re-iterate: the x35 motor is the right tool for its application. There are many applications.

Stefan Mikes

Gravel e-biker

- Region

- Europe

- City

- Mazovia, PL

I do not deny the x35 has got the torque sensor. If it has, the motor makes a lot of sense.

I don't think that sensor is there.I do not deny the x35 has got the torque sensor. If it has, the motor makes a lot of sense.

AntonioAlfaro

Active Member

- Region

- Other

Hi friends, even if the system does not have a torque sensor, it is possible to calculate it basesd on motor operation current, voltage and rpm. Every motor has its own caracteristic electric parameters. I will attach an graph example. In such case of no torque sensor, motor controller has a smart software to protect motor from burning and to operate correctly.

Similar threads

- Replies

- 241

- Views

- 35K