mikeschn

Well-Known Member

- Region

- USA

- City

- SE Michigan

My brackets are custom designed to fit the tube. I am going to be doing a new bracket to fit the triangle shape of the cypress down tube. I would think you could machine any shape you want out of delrin.Language barrier here, sorry - what is box fan shell?

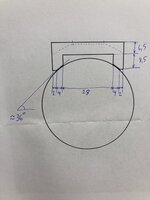

The tube is >2" diameter and thin walled, so I want any type of fixture to squeeze as uniformly around the tube as possible. Today's idea is fixing a mounting rail using 4-5 regular hose clamps, I imagine that will be pretty gentle to the tube. Unfortunately the tube is not entirely round so the type of clamps that @mikeschn suggested will not fit well (unless they are machined to the exact profile of the tube).

As for dimensions, I would have a hard time locating a 13/32" drill or a #10-32 screw.Anything in this size range is millimeters here, as you say.

But I have never heard of restrictions on consumers buying machine screws. Anyone can buy any type of screws they like, as long as you find a supplier who will sell small enough quantities.

Another option is to machine a delrin rail and secure it to the downtube using hose clamps, or cable ties... something like this maybe...

The shape of my down tube! ha!

Last edited: