The need for attention and presense of mind cannot be stressed enough.

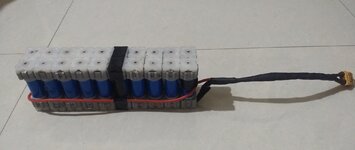

Some more goof-ups from me: I decided to build a 13s2p, 48 volts 4.4 ah battery made of same cell type (18650 Li-Ion, 3.6 volts, 2200 mah) and manufacturer. I contacted the manufacturer for the cell data sheet - didn't get one, however they mentioned the resistance is around 50 milli-Ohms per cell.

I was waiting for my SkyRC iMax B6AC version 2 to arrive (B6AC version 1 does not have the resistance meter), meanwhile I built the 13s2p, 48 volts 4.4 ah battery pack using the assembly kit, and decided to safely charge it to 54 volts using a generic 2 amp charger and a multimeter plugged in to monitor the voltage. Surprisingly, the 2 amp charger cut off when the multimeter read 53 volts.

Thankfully, I didn't use the battery pack, and once I received the balance charger, I had to remove the endcaps, busbars and strips to discharge the cells, since the openings on the endcaps are too tiny to fit in the banana plugs. I decided to discharge the cells to nominal voltage one at a time, strangely, a total of 8 cells out of the 26 were not detected by the balance charger discharge program, and when I checked the voltage with my multimeter, they read a shocking 4.4 volts.

Now I had to quickly find another way of discharging those cells. Initially I thought of ordering an smd led to discharge the cells, but later realised that I could use these cells as DC input to the same balance charger, so I hooked them up and let the balance charger discharge them to below 4.2 volts. And after all the 8 cells were discharged below 4.2 volts, now the balance charger discharge program detected those cells.

After having discharged all the 26 cells to nominal voltage of 3.7 volts (3.6 volts would be ideal, but I wanted to keep them at 3.7 as a safer option.), I measured the resistance of all the cells which range from 43 - 70 milli-Ohms, which I guess should be fine?

I figured that there were contact issues which caused the voltage disparity between the cells earlier, and after careful observation the root cause is the alignment of the strips and the cells. I need to make sure the strips are straight and make good contact with the bus bars. The spacers and the cells need to be aligned as well, and to avoid disorientation of the spacers, I have decided to shrink wrap the pack before laying the strips and bus bars, and cutout the top and bottom part of the wrap to expose the cells terminals, and then lay down the strips and busbars, hammer the endcaps, check the alignment with a leveler and once all the connections are done, shrink wrap the battery pack twice to offer extra stability, and that's not all, I will be using foam in my frame bag to cushion the riding impact.

Hope everything works out well, for all the time and effort.