Thinner rotors being preferable for instance. That set me off as patently ridiculous and a clear sign of no actual experience backing up the words.

Here's a quote that just touches on this:

And again that's you seemingly not understanding a blasted word I'm saying, and making garbage nonsense about what heat sinks are even for.

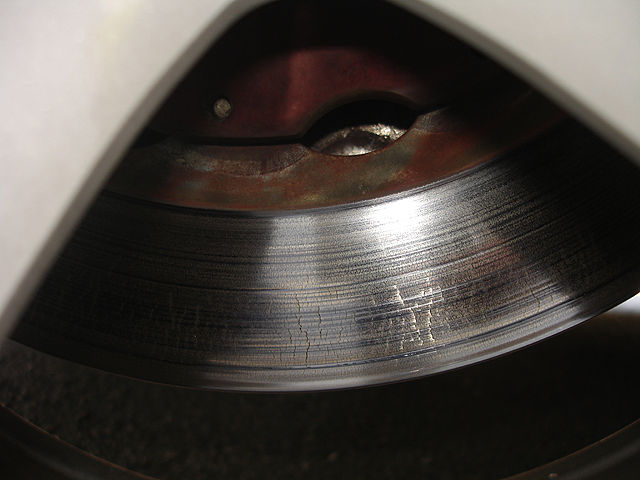

The rotor

surfaces would be thinner, I think you're thinking the overall thickness between the two contact surfaces, not the two discs on each side of the porting.

That's what it's called when manufacturing them by the way. Those "vents" into the open space and/or internal fins (also to increase surface area) are called "porting". Much akin to what you can do to the barrel of a gun to add integral kick suppression.

And that's another point of contention, you have racing experience, I have manufacturing and engineering experience. We likely wouldn't agree on terminology, much less physics.

ASCII art time.

Code:

###-----###

###-----###

### ###

###-----###

### ###

### ###

###-----###

### ###

### ###

###-----###

### ###

###-----###

###-----###

A C D B

I was talking A to C / D to B, you're talking A to B. Which means we actually kind of agree. In both cases were' talking about reducing the mass to surface ratio for better cooling. Making C to D bigger does give more surface area for better cooling in terms of porting and internal fins/pinning. But so does reducing A to B and D to C. You get better heat dissipation qualities making the two disks on each side thinner, irregardless of the total rotor width!

Though yes, total width is better when you have porting and/or internal fin stacks.

The point across the board being to get RID of heat, not blindly let the thing soak it up. More mass without increasing the surface area isn't going to provide that! It is not about more mass to store it,

it's about more surface area to get rid of it! ANYONE telling you otherwise is packing your fudge!

In the case of a bike rotor, we only have a single sheet, thus thinner is BETTER if you want to keep them cool and not have them overheat in the first place... the only limitation of that being how thin can you go before it fails structurally

And yeah, those Shimano's are expensive, but there are some aluminum sink ones in the sub $40 range. I mean FFS it's aluminum, just because crApple can charge a premium for using one of the cheapest metals doesn't make it fancy or expensive.

YBEKI sounds pretty sketchy as company names, but this is stuff any modern light machine shop could do from scratch easy-peasy.

Oh... my... God... YBEKI? Look at its rotor. It's so .... big.

Your tale of taking a 2 ton car to the track made me laugh. Reminded me of a neighbor who put Z badges on his crappy iron duke bitchin'c', then was pissed off when my even crappier el-cheapo little 1.6 liter four banger turbo slushbox Dodge Colt (a glorified Hyundai Excel) smoked him consistently the first half mile getting on the highway at exit 3 route 3 in Manomet, MA. Almost as if it was a three fifths his curb weight or something...

NOT that we ever illegally raced down the highway at 100+ in the '80's with no safety gear.

He was like a noughties kid slapping v-tec badges on stock model Civic's. The sticker makes it go faster.