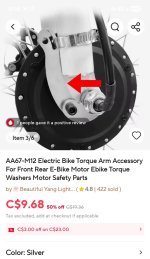

By the way I feel like I should use a torque arm as well? Or do you guys not use torque arms on such small motors? Since it is a front motor I feel like my face might thank me

You are probably fine with the torque washers that are (probably) already on your motor.

I've got the same (crappy) torque washers on both my ebikes, and the one is a 750 Watt motor that gets over 1300 watts at times,..

The torque washers are sloppy and allow my axles to rotate enough to bite into the aluminum dropouts, but they didn't spin or completely wreck my dropouts.

I think your torque washers are adequate, and adding torque arms can just add a new point of potential failure in a bad place?

You don't want anything getting stuck in your brake rotor if something goes wrong.

The big thing is keeping your wheel securely attached and trying to make sure that nothing jams or seizes and throws you over the handlebars.

(The motor failing could possibly seize the motor.)

Having your front wheel fall off is even more dangerous.

I think if you just mount your motor the way it is (with the torque tabs right side up), it would be your safest and easiest approach.

(Your forks do have "laywer lips" so if your axle bolts loosen up you should hear and feel something before the wheel falls off.)

(Keep in mind that (as far as I know) front hub motors don't play nicely with suspension forks or aluminum forks, and you can break the dropouts clean off the forks and lose your wheel. I think that's for high power motors though? You might be ok with your motor, but you are going to be super-charging it.)