Electricmover

Member

- Region

- Europe

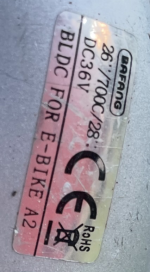

I have a 250 watt nominal front hub motor. I have a 48 volt battery and the controller that seems to work best with the wires is a 18max current controller that I have. Would this work or would it fry the motor in a winter barbecue?

I am thinking short bursts it could probably be fine now in winter right? If careful it won't fry, if gearing down in up-slopes ? Or is this a stupid idea. Maybe I should lower to max current controller of 15a?

Motor and controller is in these images.

I am thinking short bursts it could probably be fine now in winter right? If careful it won't fry, if gearing down in up-slopes ? Or is this a stupid idea. Maybe I should lower to max current controller of 15a?

Motor and controller is in these images.