I have actually done something similar recently on my Bike

Boxxbike Valkyrie : new 8kw mid drive with pedals and left hand motor drive .. customizable from 250w to 8000w up to 250Nm torque.. https://evnerds.com/ev-album/your-ebike/the-performance-e-bike/ facebook.com/boxxbike boxxbike.com

endless-sphere.com

A few things to check / clarify:

First check if your controller has an option for a torque sensor connection. If it does then that will be by far the easiest most effective way to do that, as you may even be able to connect both the torque output and the cadence info to the controller for the best possible Assist response.

If not

- Do you want to replace the throttle with the torque sensor, or have both of them in parallel (I did both in parallel)?

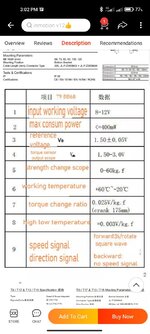

- Need to figure what is the voltage input of the throttle and what is the voltage input required for the torque sensor.

- If these are not the same, where will you source power for the Torque sensor?

- In order to be able to inject the torque sensor signal in the existing throttle connector, the Torque sensor will need to share the Ground connection with the throttle connector, so the torque sensor power source should have the same ground as the Throttle input.

- Need to figure out what is the actual output of your throttle. Easiest way to do that is to make a small harness to insert between the throttle connectors, so you can verify which wire is which and what is the voltage output of the throttle. Potentiometer throttle can have 0-5V, Hall throttle may have 0.8 - 4.3V

- Next is to install the Torque sensor bottom bracket, power it, and test its output range.

- The potential issue here is if the torque sensor output starts at a higher value than the throttle. like if the throttle starts at .8V, but the torque sensor starts at 1.2V. In that case you would need to have a way to recalibrate it so it does not always activate the motor. If the torque sensor replaces the throttle and the controller has programmable access to may be able to do that using the controller programming, if not or if you connect both in parallel, then you would need to either use electronics or use a programmable component like an Arduino to be able to calibrate the Torque sensor.

- If the torque sensor output can be made to match what is needed and you want to connect it in parallel with the throttle you will probably need to merge the two signals using a dual Schottky diode like I had to, to prevent back feed issues.

Now know that if you only have a torque sensor as your throttle signal, that will be great for MTB kind of situations, with uneven terrain and instant irregular assist need,

but it will not be great for cruising at regular speed.

When you cruise at regular speed, the pressure on the pedals is intermittent, and so the assist will be the same and therefore not very smooth or regular. This is why most pedal assist system use a combination of a torque sensor and a cadence sensor and use clever programming to blend them both depending on the circumstances.

That issue can be improved if you have a way to process the torque sensor signal, applying a Low pass filter to it, but that either require the controller to provide that, or the use of a programmable component like the Arduino.