Another update from ShareRoller today with another delay, but also lots of new details about and images of the device:

Hello ShareRoller Indiegogo backer:

First off, our apologies for the long delay in getting out this Update - we have been absolutely scrambling over the past two months trying to get every component shipped to us before our China suppliers shut down for the Chinese New Year (CNY) holiday, which falls on Feb 16th this year. The Chinese New Year is a 3-week+ shutdown for ALL factories that we were trying our hardest to avoid...

Unfortunately, we didn't make it and now several suppliers will not be able to deliver components until after the break, namely our Battery Pack and Wireless Controller suppliers. This means it will be the end of February at the earliest before we can expect to receive these components, and more than likely will slip into March, given the slow start-up that is common after this holiday. This is an enormously frustrating scheduling impact for us, and we understand it is equally painful for our Backers as well. Please accept our apologies for this further delay and know that we are doing everything we can.

Several main issues pushed us past the CNY holiday shutdown:

Wireless Controller Waterproofing: During wet weather testing, we discovered that our wireless controller housing was not adequately protected from water ingress. Given the multitude of controls and ports on our remote (Single-axis joystick, two buttons, two switches, and a Micro-USB port), a standard rubber seal was not effective enough. So we had to go back to the drawing board and design a custom latex bladder to enclose all the electronics, and move to an IP67-rated Micro-USB port since that needs to be exposed.

Wireless Controller FCC Certification: We had understood that FCC certification was already completed by our wireless controller supplier, since the base wireless architecture is already in commercial use. Unfortunately, we've learned that Chinese suppliers often complete only CE certification for wireless, since the FCC process is so expensive and time-consuming. So we've had to pay for complete FCC certification on our own, and it's not just expensive but also time-consuming. Hence the delay.

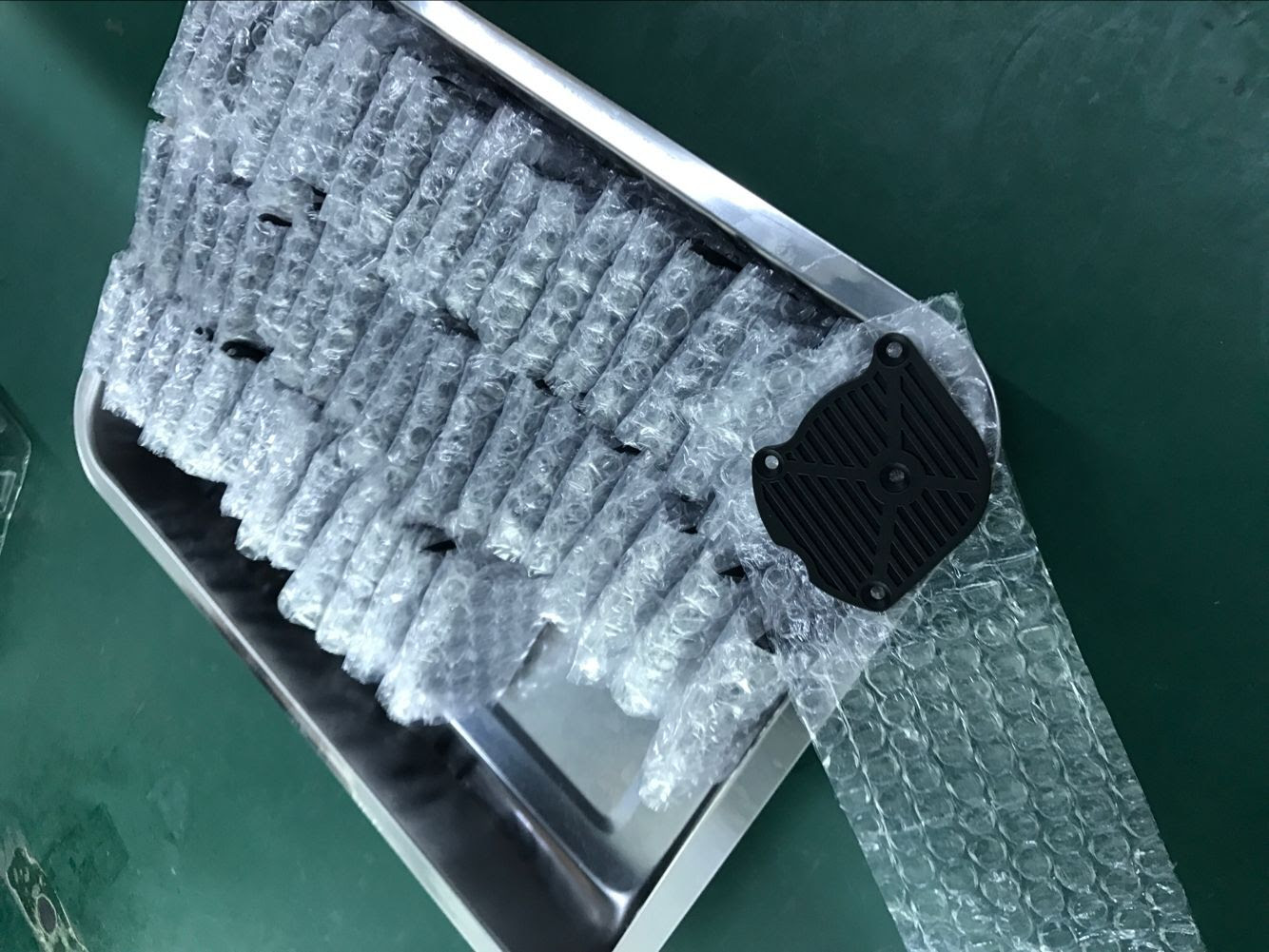

Battery Pack Mold Tooling : We've been unbelievably frustrated at how long it has taken to start the tooling for the battery pack molds. Believe it or not, we paid our deposit for these molds back in April 2017 (!), and we've expected the mold to start month after month after month since then. So we haven't been misleading you when we've said the tooling was about to begin, again and again. To our great frustration, there has been one change request after another from the molding engineers in China, and many of them have not been acceptable, so we've had to go through prolonged back and forth design iterations to find a workable solution. I can count nearly 500 emails this year alone between us and our battery supplier! BUT, at long last the design has passed final approval on both sides and the molds will start tooling this week. Our supplier is doing their best to expedite the lengthy tooling process (normally 6 weeks), so we're hoping to have it done by the end of February, and then Battery Pack assembly can begin (a much quicker process).

Given all of the delays with the Battery Packs, we've unfortunately had to postpone production of the Ultra size packs. However, with the advances in Lithium battery cell tech over the past two years, and the fact that we're using the highest-quality cells on the market (and most expensive!), our Standard packs now have 300 Watt-hours of capacity, nearly 40% more than we originally promised for the Standard pack, and 75% of the range of the original Ultra spec. Regardless, we will still offer partial refunds for all of our Ultra pack Backers, which of course could be applied to extra packs if you wish! And some good news for all the 'Mini' Backers out there too - the final capacity spec is 130 Watt-Hours for the Mini packs, almost 20% more range than originally promised!

Now that all the disappointing news is out of the way, at long last we can show you ALL the glorious details of the final design. We're very sorry to have kept you in the dark for so long on exactly what you would be getting (!), so we're thrilled to finally share all of the pics and details below. We are in the process of updating our website for Pre-Orders, but the photo and video shoots are taking much longer than expected. So in the meantime here is a sneak-preview of the all-new SR4 -apologies for the renders only, but we should have photos soon and will share them with you as soon as do.

First off, here's how the SR4 looks when assembled and carried: the Mini is shown below - it really is tiny:

And here is an annotated pictogram of the assembled SR4 package: Battery Pack + Motor Module + Wireless Remote (again, the Mini version is shown below)

And here is a close-up annotated pictogram of the SR4 Motor Module alone- the feature-packed heart and soul of ShareRoller:

And here are the key measurements of the Mini vs Standard combinations.

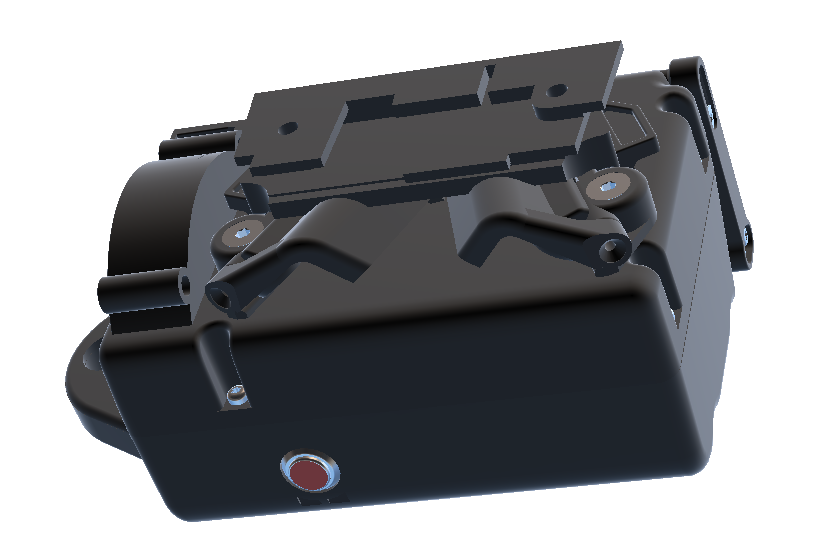

And since it's hard to see every detail with two pics, here's a rotating pictorial of the Motor Module so you can see it from every angle:

Now for some detail on SR4's groundbreaking new Automated Traction Control System (ATCS) with Motorized Normal Force Control. This Patent-Pending technology transforms the century-old technology of Friction Drive, making it finally competitive with more common E-Bike powertrains. We've described this to you previously, but here is a LOT more detail - hopefully this will make you appreciate the significance of this advance (and all the work it has entailed!):

Here's a small video animation to sum up how it all works:

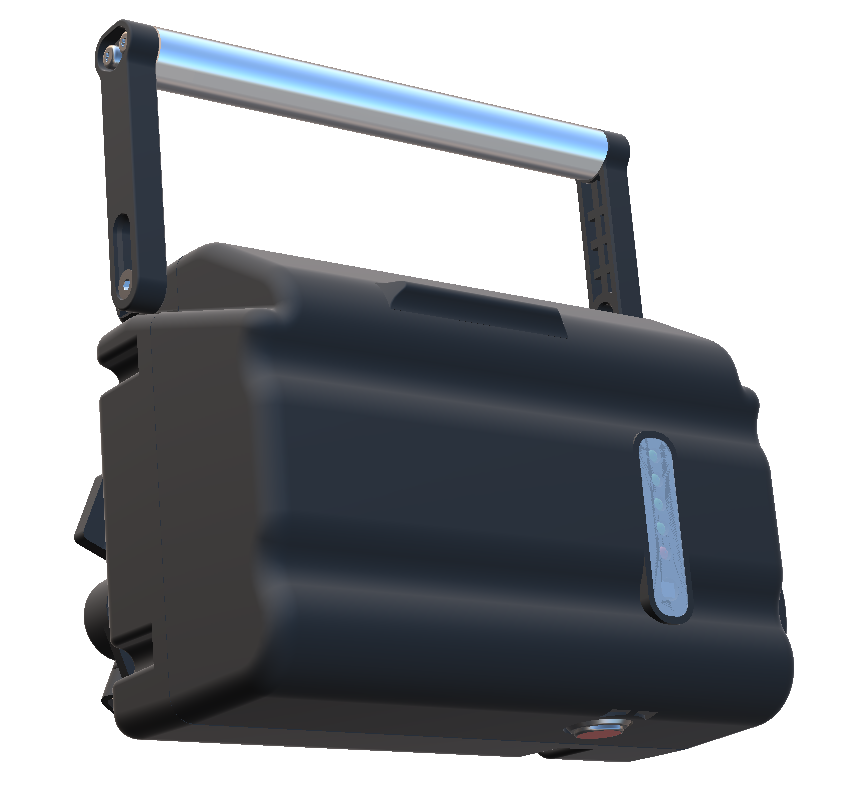

And now on to our completely custom wireless controller. We looked at all the available E-Bike and E-Skate throttle systems on the market, and none of them came close to what we wanted for a truly removable and portable system. And none had the feature-packed functionality we desired. So we designed our own implementation (using existing wireless tech), creating a completely unique form factor that gives vastly more versatility in mounting options, and significantly better control options than anything else on the market.

With a dual-direction infinitely variable 'joystick' controller for Throttle and Brake, a second 'Throttle Mode' switch, and two separate buttons, this controller offers way more 'control' than anything else out there. It also works in tandem with our optional PAS sensor (coming soon), so you can easily adjust assist levels on the fly, activate Regen Braking, and control Drive Motor engagement as well (for when you want to pedal without any motor assistance and eliminate drag).

With a built-in rechargeable battery and Micro-USB port plus two battery/signal LEDs, you'll find it incredibly convenient to use as well. And we've also figured out a clever way to attach the throttle to the battery pack using a high-strength magnetic attachment point. It's super-quick to snap on/off and makes the whole Install/Remove for SR4 as fast and easy as possible.

This has taken a ton of work, and for competitive reasons we've kept it under wraps for as long as possible, but at long last we're ready to share it with our Backers. We hope you like it!

And finally, an update on mounting options: if you recall, we've told you previously that the new SR4 design supports multiple mounting options, including both front and rear wheel installations (as a reminder, you will still be given a chance to update your mount options prior to shipment). So let's look at all the mount options more closely:

Zooming in on some close-ups - first of the Front Universal Mount (note that we have Front U-Mounts that fit both Suspension and Non-Suspension forks, as well as both V-Brakes, Disc Brakes, and Side-pull brakes):

And a perspective view of the Rear Wheel Kickstand Bracket U-Mount - we were thrilled to validate that the SR4 will fit between the pedal cranks and chainring of most bike types:

And finally, of the Rear Wheel Seatpost U-Mount and Rear Wheel Topeak MTX Rack Mount. Note that both of these mounts also offer the option to attach the Battery Pack to the mount itself, making for a 'one-piece' ShareRoller installation. And since they are both Quick-Release designs, these can be installed in seconds even for the first installation, and without a single tool! A great option for Rental Bikes or other situations where you want to ride a 'loaner' bike:

Keep in mind that our Front Universal Bike Mount will also work on any other platform with V-Brakes, including many Folding Bikes (Dahons for example), Kick Bikes (Sidewalker, KickBike America, Amish) and some Kick Scooters (like the Sidewalker Micro we have here in our office).

In addition to the amazing new set of Universal Bike Mounts, we also are busy with our 3D Scanner finalizing Custom Mounts for unique folding bikes, trikes, and scooters. Here's a partial list of what we're developing - if anyone has any specific requests, please let us know:

Folding Bikes:

- Brompton

- Strida

Trikes:

- Trikke T78

Kick Scooters:

- Hudora Big Wheel Air Dual-Brake

- KickPed

- Razor A5/A6

- Micro PedalFlow

To give you a sense of how our Custom Mounts work, here's an image of 3D-scanned Brompton with a Custom Mount (we hope our Brompton backers are as thrilled as we are that the new SR4 can remain on the bike when folding without any interference!):

And one last detail: here is how our quick-release mount for the Battery Packs works (you've probably been wondering how we could keep the sub-10 second install/remove of the 1-piece ShareRoller when moving to a separate, frame-mounted Battery Pack). The solution? It uses the Topeak QR CageMount removable water bottle mounting system - a robust and affordable system that's easy to install on every bike you own. Here's how it works:

And since it mounts to the bike using standard water bottle braze-ons, if your bike (or scooter) doesn't have braze-ons, many off-the-shelf products are available to easily add them on (secured via velcro, zip-ties, or clamps - we'll provide a list of our favorites later).

And if you want to use ShareRoller on a compatible bike share system (please consult your system operator first), you'll prefer our Multi-Mount Battery Pack option. It's a little bit bulkier, but allows you to have both bike share triangle pockets as well as a Topeak QR CageMount bracket disposed on the same Battery Pack:

Whew, that's it for now. We hope this gigantic email made its way into your Inbox successfully. And that you found the time to read it all!

We'll keep you posted as we finish photo and video shoots and move to re-launch

www.shareroller.com - so there's lots of great content on the way. And of course we will keep you updated on the progress of our last straggling supplier deliveries.

Thank you again for your patience and support.

Jeff Guida & The ShareRoller Team