Hello,

I started looking for the possibility of charging the battery from the solar battery on 09/30/2019.

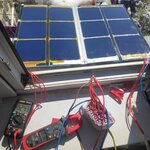

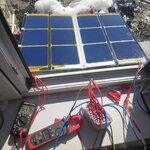

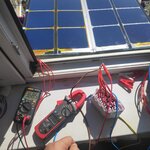

At the moment, I have intermediate test results for various solar cells.

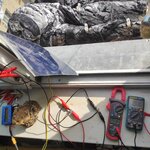

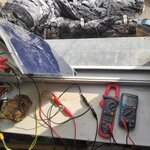

On the test there were the classic cells (very very fragile, contact tracks on the front side) monocrystall and polycrystall and defective cells from Sunpower Maxeon C60 monocrystal.

Cell selection criteria were:

1) convenience of soldering cell contacts

2) mechanical strength, requirements for the substrate material

3) power output

Classic cells did not pass by the first two criteria - the contacts are very poorly soldered, there are many dirty traces on the surface.

Also, the cells are very fragile, it is impossible to clean the surface without the risk of damage. A stiff backing is required.

By all criteria, the Sunpower Maxeon C60 cell passed.

Moreover, tests showed that even damaged cells (diagonal kinks) and under laminating film are able to generate 60-100% - same output power on light load, less output power for high load like 'Short Circuit'.

It's totally crazy on the background of classic fragile cells!

On these Sunpower Maxeon C60 cells I will build the solar panels.

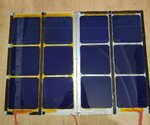

Decided on the format of the battery - two sheets of size A3, 6 cells per sheet.

Rated voltage 6V under load.

Thus, I will build a minimum of 4 batteries with a nominal voltage of 24V.

Charging will be through a boost converter.

I also want to try to charge the battery by reconnecting the parallels via tp4056 modules or directly to the solar panels (connected in parallel).

The goal is not to charge 100% 4.2V, but at least up to 4.0-4.1V, which is very very good in conditions of remoteness from civilization.

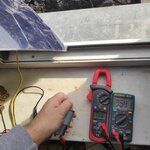

Now tested options for protecting cells from the environment by lamination and epoxy.

A noticeable drop in power due to the material was not noticed.

The path through the lamination is more than attractive due to its simplicity and low weight, unlike epoxy resin.

I printed out the contours of cells in the form of 2x3 on a sheet of paper A3. The distance between the row of cells and the edges is at least 1 cm for better welding of the lamination film.

Next, you have to choose the substrate material. Of the available options, this is plexiglass 1 mm thick and textolite 0.5 mm thick.

Both materials are good, but I think under high temperature in the summer the textolite will be more hardy.

Project current status - waiting for a batch of non-defective cells of 50pcs Sunpower Maxeon C60.

I will be glad to comment on this project, which could help in the future.

--

Text was translated from ru via translate.google.com

My original source https://electrotransport.ru/ussr/index.php?topic=60003.0

I started looking for the possibility of charging the battery from the solar battery on 09/30/2019.

At the moment, I have intermediate test results for various solar cells.

On the test there were the classic cells (very very fragile, contact tracks on the front side) monocrystall and polycrystall and defective cells from Sunpower Maxeon C60 monocrystal.

Cell selection criteria were:

1) convenience of soldering cell contacts

2) mechanical strength, requirements for the substrate material

3) power output

Classic cells did not pass by the first two criteria - the contacts are very poorly soldered, there are many dirty traces on the surface.

Also, the cells are very fragile, it is impossible to clean the surface without the risk of damage. A stiff backing is required.

By all criteria, the Sunpower Maxeon C60 cell passed.

Moreover, tests showed that even damaged cells (diagonal kinks) and under laminating film are able to generate 60-100% - same output power on light load, less output power for high load like 'Short Circuit'.

It's totally crazy on the background of classic fragile cells!

On these Sunpower Maxeon C60 cells I will build the solar panels.

Decided on the format of the battery - two sheets of size A3, 6 cells per sheet.

Rated voltage 6V under load.

Thus, I will build a minimum of 4 batteries with a nominal voltage of 24V.

Charging will be through a boost converter.

I also want to try to charge the battery by reconnecting the parallels via tp4056 modules or directly to the solar panels (connected in parallel).

The goal is not to charge 100% 4.2V, but at least up to 4.0-4.1V, which is very very good in conditions of remoteness from civilization.

Now tested options for protecting cells from the environment by lamination and epoxy.

A noticeable drop in power due to the material was not noticed.

The path through the lamination is more than attractive due to its simplicity and low weight, unlike epoxy resin.

I printed out the contours of cells in the form of 2x3 on a sheet of paper A3. The distance between the row of cells and the edges is at least 1 cm for better welding of the lamination film.

Next, you have to choose the substrate material. Of the available options, this is plexiglass 1 mm thick and textolite 0.5 mm thick.

Both materials are good, but I think under high temperature in the summer the textolite will be more hardy.

Project current status - waiting for a batch of non-defective cells of 50pcs Sunpower Maxeon C60.

I will be glad to comment on this project, which could help in the future.

--

Text was translated from ru via translate.google.com

My original source https://electrotransport.ru/ussr/index.php?topic=60003.0

Last edited: