Hello fellow e-bikers,

I have some confusion about mixing 18650 Li-Ion cells of different mah while building a custom e-Bike battery pack.

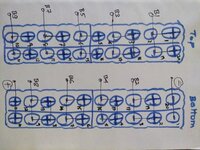

I built a battery pack with 18650 li-ion cells with the configuration 10s2p using 3.6v, 2200 mah cells and a compatible 10s 36v BMS rated for 15amps. The pack was all fine except for the low range. Charging and Discharging cycles worked fine with the BMS cutting off at 40v and 36v.

To better the range I had to add more cells to the battery pack. I had 10x 18650 li-ion cells rated 3.6v, 2400mah. I reconfigured the pack by adding another row of cells in parallel to make it a 10s3p battery pack. So now I had 20x 2200mah and 10x 2400mah.

I charged the battery pack and there was no issues. It charged to 40v and was cut off by the BMS. The scary issue I faced when I took it for a ride is that the battery pack kept discharging below 36v and I stopped when it reached 34.8v. This wasn't the case before adding the 2400mah cells. I'm not sure if mixing different mah cells was a good idea.

I assumed this could be because of cells with charge imbalance, so to check, I once again charged the battery pack and the charging cut off at 40v. Before I take it out for a ride again to check if the discharging cuts off at 36v, I'd like to know your opinions about the configuration.

I checked online and found conflicting advice about mixing cells of different mah and brands.

I have some confusion about mixing 18650 Li-Ion cells of different mah while building a custom e-Bike battery pack.

I built a battery pack with 18650 li-ion cells with the configuration 10s2p using 3.6v, 2200 mah cells and a compatible 10s 36v BMS rated for 15amps. The pack was all fine except for the low range. Charging and Discharging cycles worked fine with the BMS cutting off at 40v and 36v.

To better the range I had to add more cells to the battery pack. I had 10x 18650 li-ion cells rated 3.6v, 2400mah. I reconfigured the pack by adding another row of cells in parallel to make it a 10s3p battery pack. So now I had 20x 2200mah and 10x 2400mah.

I charged the battery pack and there was no issues. It charged to 40v and was cut off by the BMS. The scary issue I faced when I took it for a ride is that the battery pack kept discharging below 36v and I stopped when it reached 34.8v. This wasn't the case before adding the 2400mah cells. I'm not sure if mixing different mah cells was a good idea.

I assumed this could be because of cells with charge imbalance, so to check, I once again charged the battery pack and the charging cut off at 40v. Before I take it out for a ride again to check if the discharging cuts off at 36v, I'd like to know your opinions about the configuration.

I checked online and found conflicting advice about mixing cells of different mah and brands.