Hi all

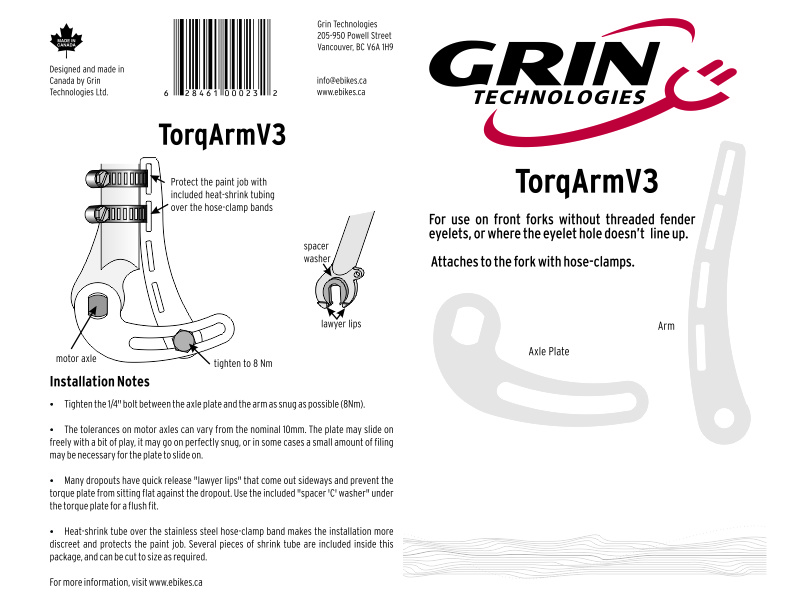

I have joined the newsgroup today and it looks very good and informative so much so that I feel compelled to seek your help so soon , I own two electric bikes , a electric car since 2016 and have un the same year and installed enough solar panels to charge em all , but back to the point in question, my recent acquisition is a diy front wheel convertible which was a dream to install, but since assembling it I discovered that there is a potential problem round the corner in as much as the torque arm kit I purchased looks far to flimsy and is secured with a hose clamp ! can anyone suggest a more secure way of doing it , cheers and thanks in anticipation

Ronnac

I have joined the newsgroup today and it looks very good and informative so much so that I feel compelled to seek your help so soon , I own two electric bikes , a electric car since 2016 and have un the same year and installed enough solar panels to charge em all , but back to the point in question, my recent acquisition is a diy front wheel convertible which was a dream to install, but since assembling it I discovered that there is a potential problem round the corner in as much as the torque arm kit I purchased looks far to flimsy and is secured with a hose clamp ! can anyone suggest a more secure way of doing it , cheers and thanks in anticipation

Ronnac