PCeBiker

Well-Known Member

- Region

- Canada

The whole rack almost broke off the ebike with my battery attached to it.

If it wasn't for this Allen bolt, the rack would have broken off the e-bike.

That bolt hole shouldn't be slotted.

The bolt can too easily slide in the slot regardless of how hard you torque the bolt.

There's too much lateral force pounding on it.

Luckily I had zip ties to secure it enough to make it home,..

I looks kinda bad-ass without the rack and fenders.

I had to strap the rear brake light from rack to the swing arm while I figure out what to do.

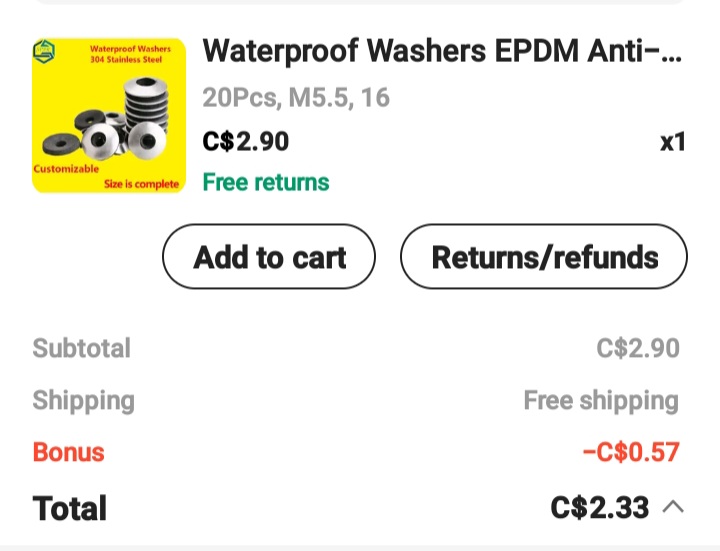

I bought this stuff to see what I can make.

I'm going to try my luck at aluminum brazing.

I suck at welding but I'm OK at soldering.

This is almost the same but hotter,..

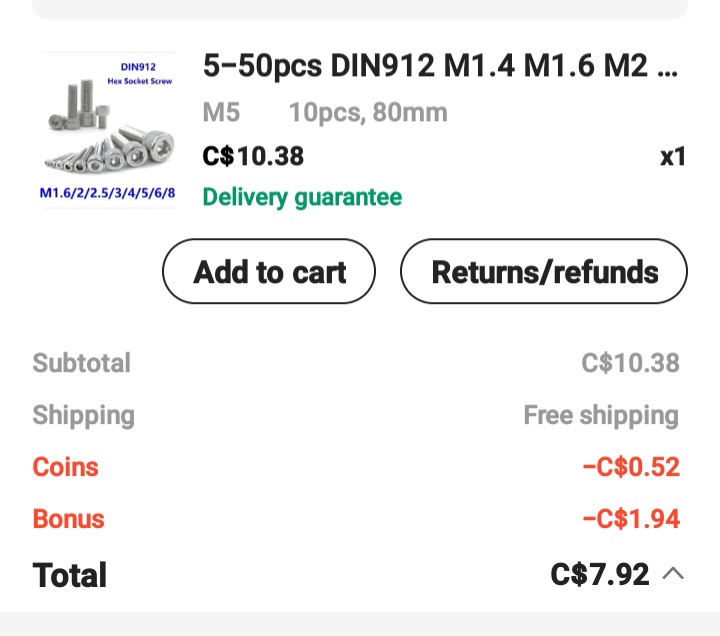

And a bunch of U-Bolts and stainless steel hardware,..

If it wasn't for this Allen bolt, the rack would have broken off the e-bike.

That bolt hole shouldn't be slotted.

The bolt can too easily slide in the slot regardless of how hard you torque the bolt.

There's too much lateral force pounding on it.

Luckily I had zip ties to secure it enough to make it home,..

I looks kinda bad-ass without the rack and fenders.

I had to strap the rear brake light from rack to the swing arm while I figure out what to do.

I bought this stuff to see what I can make.

I'm going to try my luck at aluminum brazing.

I suck at welding but I'm OK at soldering.

This is almost the same but hotter,..

And a bunch of U-Bolts and stainless steel hardware,..

Last edited: