PCeBiker

No-Hands No-Pedaling No-Credentials

- Region

- Canada

A Big Thanks to @Mike TowpathTraveler

I realized that I wanted something like that to mount my rack, but I didn't know what would work with my hub motor.

Then, I thought of torque arms,..

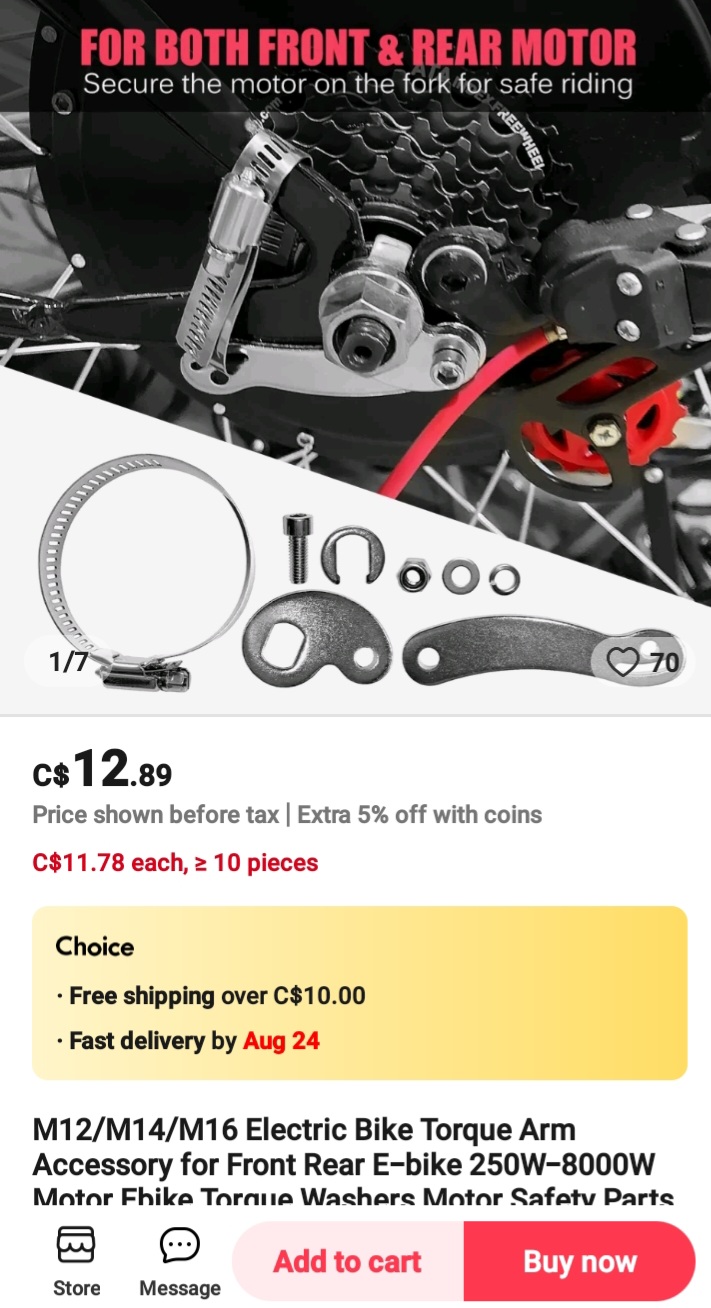

There were lots of stainless steel versions available, but they were all 14mm X 10mm, and I needed 12mm X 10mm.

They are also galvanized iron, so I can use my brazing rods on them or my arc welder in case I need to weld the two arm pieces together if the pounding of my battery bag wants to rotate my axle.

Welding the arms together would also help to utilize the torque arms for there original purpose to keep the axle from spinning.

I can delete the washers on my axle, so I can easily accommodate a 3-4mm thick torque arm on both sides.

I bought this rear rack, which should allow me to both lower the entire rack closer to the tire, and have the rack legs almost vertical to stop the cantilevering of the whole rack assembly.

If I can lower the rack about an inch or so, I should be able to move my battery bag 2-3" forward without worrying about my seat hitting it when my seatpost and swing arm compress.

I'll be flipping the arms backwards to stick out behind the axle where there's clearance for the adjustable rear rack legs to attach to them.

I will delete the chain stay clamps, and bolt directly to the torque arms.

I included lots of pictures for CanNik and Dave to enjoy.

And BTW, my rack was rated for 50# and my battery bag weighed 19# with the battery and tools I had in it.

The rack is a proprietary rack (as far as I know) because of the bolt hole spacing and I'm sure a new one would cost over $100.

I had the battery bag installed for less than two months before it broke the rack, and with four more months of riding left, I would need to order at least 3 more racks to get me through the season, and I'd have to carry a spare with me to replace on the side of the road when it breaks in a month or two.

That would suck, and it's expensive.

View attachment 179635

Good closeup I did of the finished OMM front rack.

I realized that I wanted something like that to mount my rack, but I didn't know what would work with my hub motor.

Then, I thought of torque arms,..

There were lots of stainless steel versions available, but they were all 14mm X 10mm, and I needed 12mm X 10mm.

They are also galvanized iron, so I can use my brazing rods on them or my arc welder in case I need to weld the two arm pieces together if the pounding of my battery bag wants to rotate my axle.

Welding the arms together would also help to utilize the torque arms for there original purpose to keep the axle from spinning.

I can delete the washers on my axle, so I can easily accommodate a 3-4mm thick torque arm on both sides.

I bought this rear rack, which should allow me to both lower the entire rack closer to the tire, and have the rack legs almost vertical to stop the cantilevering of the whole rack assembly.

If I can lower the rack about an inch or so, I should be able to move my battery bag 2-3" forward without worrying about my seat hitting it when my seatpost and swing arm compress.

I'll be flipping the arms backwards to stick out behind the axle where there's clearance for the adjustable rear rack legs to attach to them.

I will delete the chain stay clamps, and bolt directly to the torque arms.

I included lots of pictures for CanNik and Dave to enjoy.

And BTW, my rack was rated for 50# and my battery bag weighed 19# with the battery and tools I had in it.

The rack is a proprietary rack (as far as I know) because of the bolt hole spacing and I'm sure a new one would cost over $100.

I had the battery bag installed for less than two months before it broke the rack, and with four more months of riding left, I would need to order at least 3 more racks to get me through the season, and I'd have to carry a spare with me to replace on the side of the road when it breaks in a month or two.

That would suck, and it's expensive.