Tom@WashDC

Well-Known Member

- Region

- USA

- City

- Loudoun County, VA.

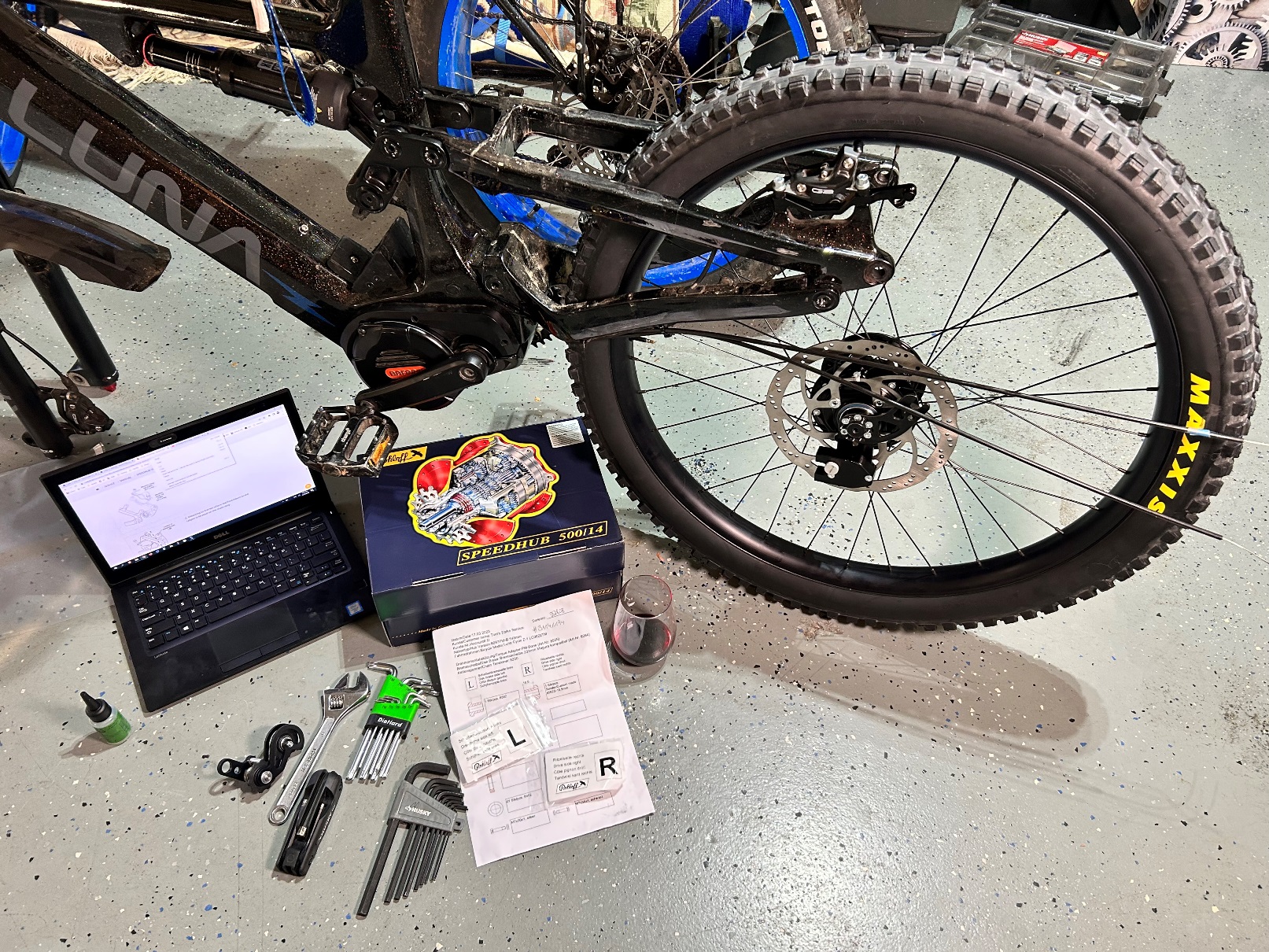

After a year of researching, speaking to owners and dealers of the Rohloff Speedhub, I've decided to ditch my 12-speed cog/derailleur system and install the Rohloff Speedhub 14 IGH on on my carbon fiber Luna Z1 Ultra Mag. The kit arrived by UPS today. I'm very excited to build the wheel, install the hub, and ride the bike with this new fangled contraption. This will be a record of my journey for those that are interested in such things. For the record I have never ridden a bike with a Rohloff IGH. My last IGH was a birthday present in 1967, a Raleigh, 3-Speed English Racer.

THE KIT

The kit contains:

Rohloff A14 Speedhub. The A14 is specifically designed for a Thru-Axle rear hub and must be specifically authorized by Rohloff for your specific bike.

Custom Drop Out Axle Adapters

Twist Shifter, cables, and External Gear Housing

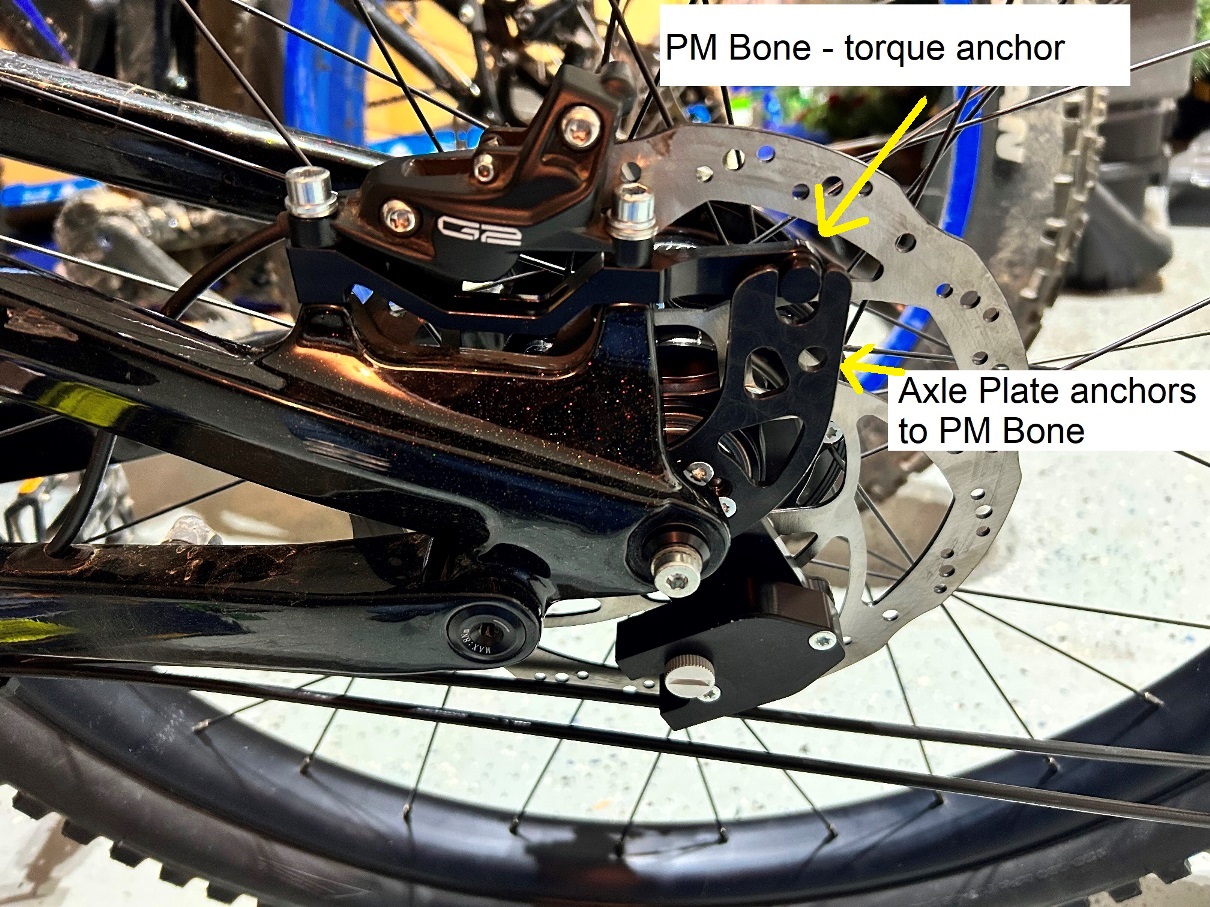

Axle Plate (torque arm)

PM Bone (to attach the torque arm to brake post mounts)

Oil for first install. The Rohloff is oil filled.

Rohloff oil change and cleaning kit. (change oil every 3,100 miles)

Downhill Chain Tensioner (for rear suspension bikes)

16T rear cog - sized (as per Rohloff) in relation to the 40T front chain ring, factoring the 160NM crank output of the Ultra Mag mid drive.

203mm 4-hole brake disc

36 - Sapam Race, pre-cut spokes and nipples (4 extra).

Additional Purchases for the install.

Chain Guide

27.5" Velocity Dually MTB Rim

KMC 8-Speed EBike chain designed for mid-drives. (single speed chains will not fit the Downhill Tensioner.)

SQLabs grips with short right grip for twist shifter.

Rohloff manufactures several IGH Speedhub 14's to accommodate differing drop outs. There is the E14 Electric shift versions, thru-axles, solid threaded axles, Quick Release axles, Fat Hubs, and hubs from 135mm O.L.D. to 197mm.

If you are installing the hub on a Thru Axle bike (like mine), Rohloff will not sell you a hub unless you use their special measuring kit and take specific measurements of your dropouts, and their thickness. Once you take the measurements, you record them via their online form along with the serial number of your bike. The Rohloff engineer will check your measurements, and if everything checks out, they will authorize a Rohloff dealer to sell you the A14 along with adapters specific to your dropouts. The measuring kit cost $350.00, and they will refund you your money once you send the kit back whether you purchase a hub or not. I had a devil of a time finding a dealer with a kit. All of the local dealers/distributors and service centers said their kits were out on loan, and they had no idea when they would be returned, or they did not stock the kit. I finally contacted Rohloff in Germany and they put me in touch with Peter White of Peter White Cycles. He had a kit and sent it promptly. I took the measurements and sent my results to Rohloff. Two weeks later their engineer contacted me and said something wasn't right. He asked me to measure again twice, and resend the measurements. It turns out their instructions said to "measure the dropouts without any additional components". I took that to mean without the derailleur hanger. Turns out I was wrong, and once we cleared that up, the measurements came back fine and, another week later, Rohloff gave me authorization to order the hub through the dealer. I returned the measuring kit and received a credit on my speedhub order. Peter White Cycles has been very helpful.

The Measuring Kit

My Bike: Luna Z1 Ultra Mag, Carbon Fiber.

From Rohloff:

"If you are ever unfortunate enough to have a SPEEDHUB stolen, then please inform us of this so we can flag the serial number as such. Nearly every SPEEDHUB returns to our service department at some time for servicing or conversion work. The relevant authorities will be informed if hubs arrive where the serial number is flagged as stolen. We have to date managed to return approximately 50% of all stolen hubs to their rightful owners."

4/21/23 - Wheel Lacing

FYI - The Rohloff installation manual and documentation are extensive.

I opted for a new rim, and laced the hub using 2X cross pattern recommended by Rohloff. The rim is a Velocity Dually 27.5" mid-fat/fat-race with a French nipple pattern. I sent the wheel ERD to Rohloff so they would cut the spokes with my order. Spokes are Sapim Race 1.8mm.

Rohloff recommends tensioning the spokes to 1,000N. I got as close as possible using my $25 spoke tension meter and the Park Tool Conversion Chart. Put a new tire on the rim, and took the wheel to my LBS and have theme equalize the spoke tension to 1,000N and compare my tension specs to theirs, and calibrate my tension meter for future reference.

"32/36 spoke SPEEDHUB wheels are typically far stronger than their derailleur counterparts. The strength is approximately equal to a 48 spoke tandem wheel of the same diameter.The SPEEDHUB spoke flanges are symmetrically positioned which places the rim directly in the center of the shell. Spokes on both sides of the wheel are therefore the same length and rest at the same angle which enables them to be tensioned equally." - Rohloff Manual

4/22/23 - Spokes Tensioned at local LBS

Installed the tire on the rim, which I taped for tubeless. Filled it with sealant, inflated it, and took it to my local TREK Bike store to have spokes tensioned to 1,000N. The guys at the store were very interested in my Rohloff hub. They'd heard about them but had no real working experience with them. The wheel builder complimented me on the build, apparently my $25.00 spoke tension meter pictured above was calibrated right on target. My spokes were tensioned well within an acceptable margin of error. No need for adjustments.

4/23/23

The twist shifter is pretty easy to install. Rohloff has a Youtube video and simple written instructions. Piece of cake.

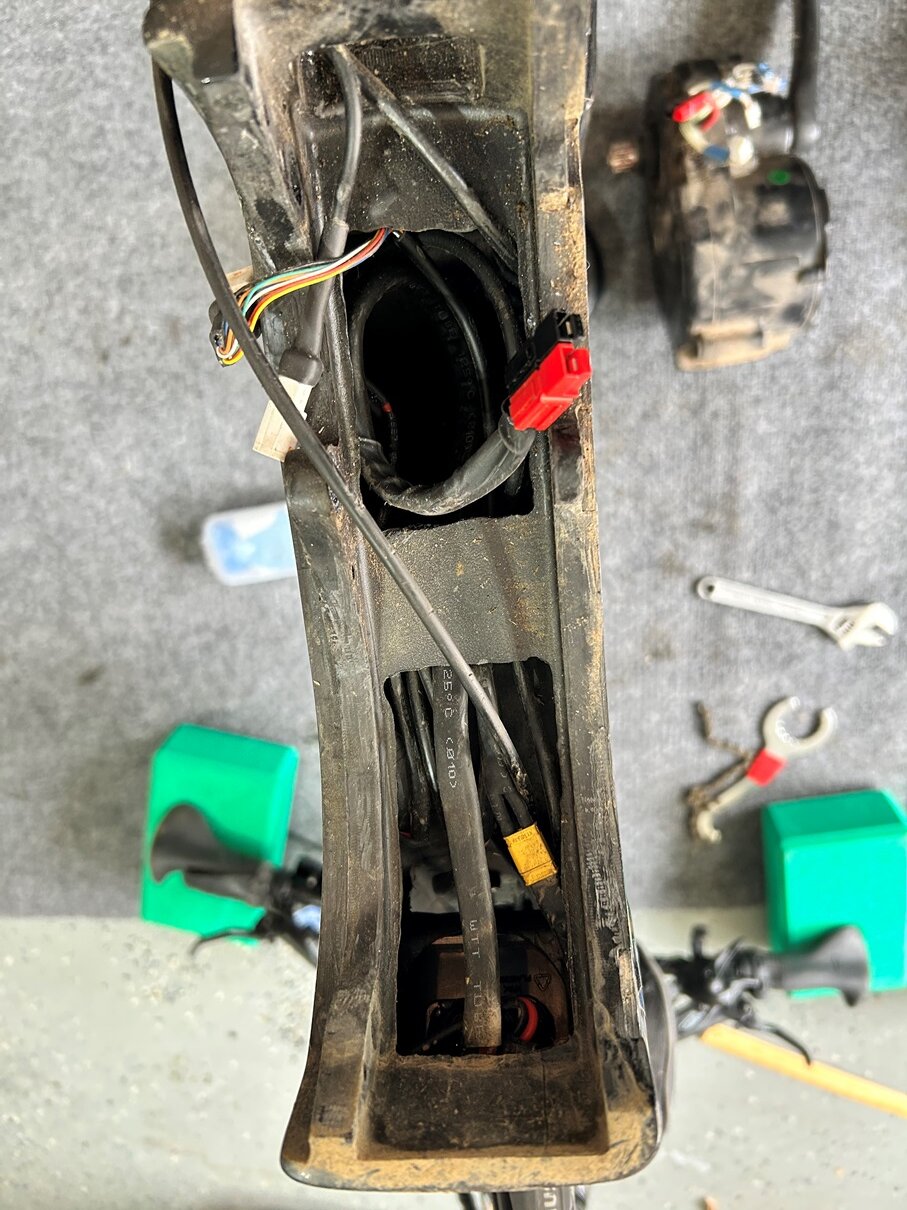

I decided to route my cables inside the down tube. I removed the battery locking mechanism, brackets that secured the existing cables in the downtube, removed the Bafang motor, and routed the cables behind the battery, behind the motor, and out the rear suspension opening in the frame. The shifter cables will run neatly under the left hand chainstay using existing zip tie anchors.

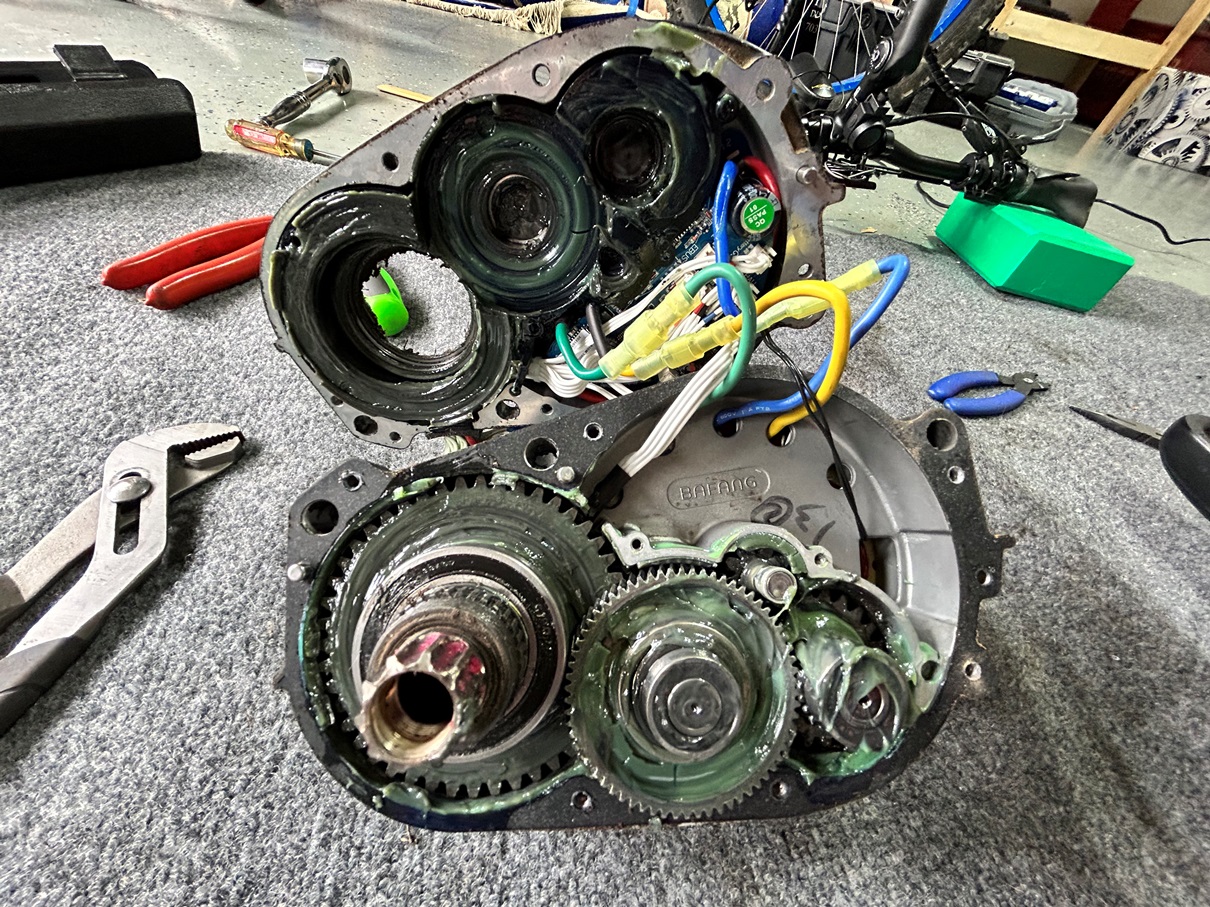

Checked Motor Grease while I'm here:

Back in July 22', after about 600 miles on my bike, I decided to check the factory grease. I found it to be paltry at best. The motor was a considerably noisier than my existing Luna/Bafang BBSHD which seems to run nearly silent. In July 22 I installed Corn Head grease. See my thread here Corn Head Grease Install. Today, opened the motor after 2,000 more miles and I was pleased, grease everywhere. The system is well lubed, and very quiet. I slathered a few more tablespoons of grease and closed the motor.

6:00 PM A glass of cabernet, I'm ready to install the wheel and hook up the shift cables to the shift mechanism.

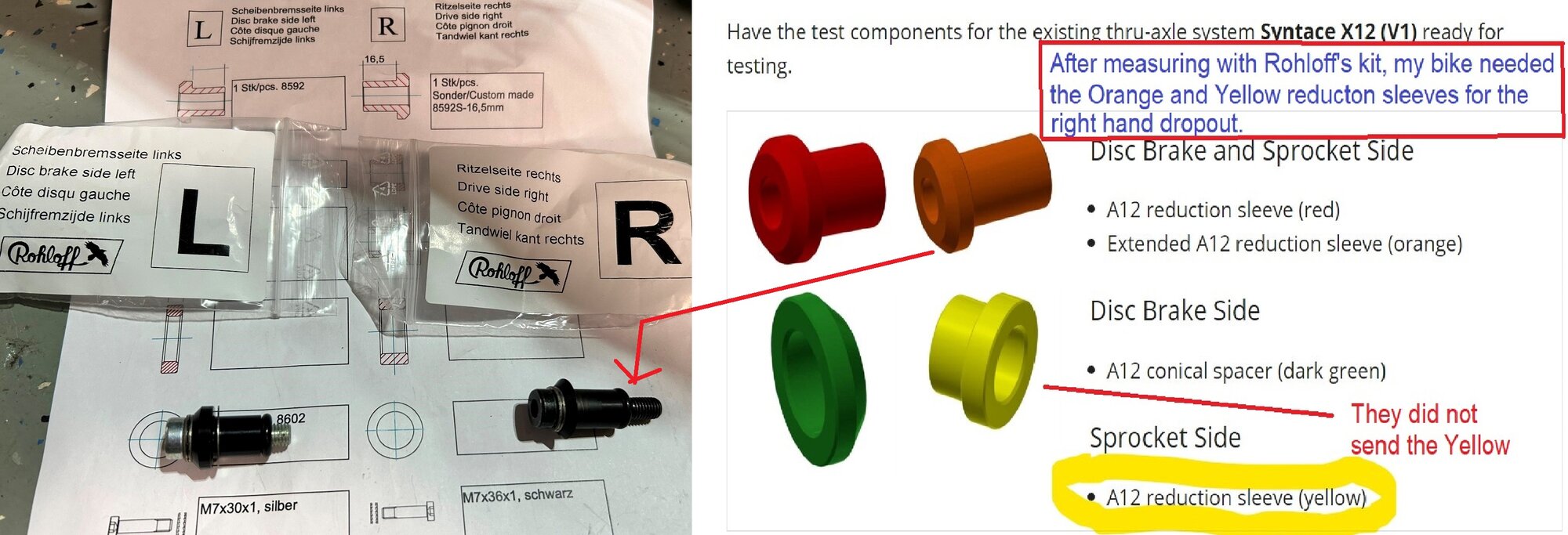

Except there is a glitch:

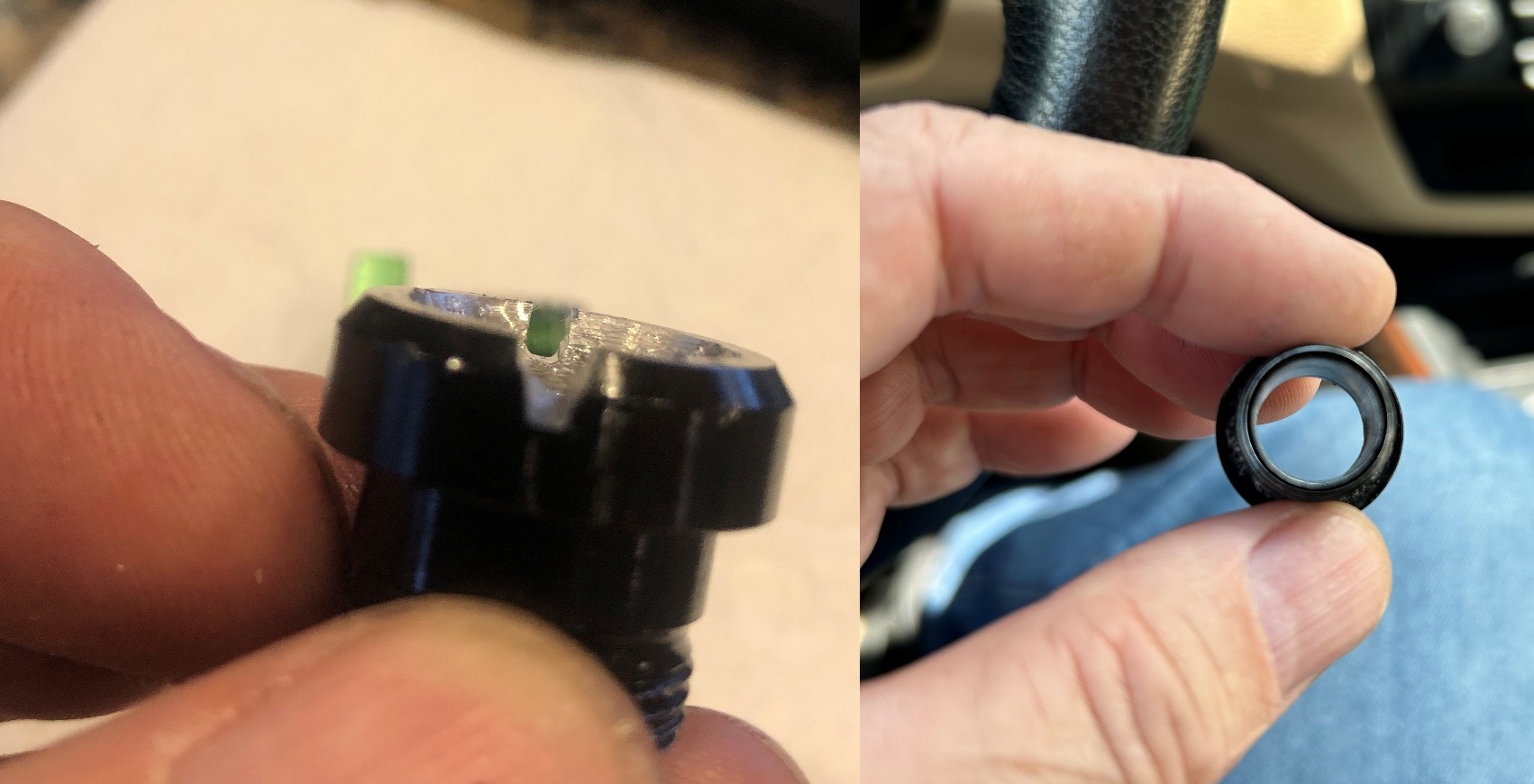

The left hand axle adapter is OK. The right hand axle adapter is OK, but either Rohloff or the dealer forgot to include the right hand (sprocket side) Reduction Sleeve below. The sleeve is Yellow in the diagram, but it comes in black. I emailed Rohloff and the dealer. I'll call them in the morning. Hopefully it won't take too long to get one...

Tasks Remaining:

4/24/23 - Machined my own adapter while I wait for Rohloff.

I figure that Rohloff and the dealer will take at least a week to get me the correct right side dropout reduction sleeve (above Yellow). I decided I cannot wait. The right hand drop out of the Luna Z1 has a threaded insert that slides into the dropout and screws into the derailleur hanger on the opposite side of the dropout. It's threaded on the inside too, to anchor the thru-axle. I took the insert to a machine shop and they drilled out the inner threads to a 12mm smooth bore, which is the diameter of the Rohloff supplied right hand axle adapter above. Screwed it back into the dropout, and slid the Rohloff axle adapter into the fitting. It fits perfectly. - Problem solved. - The Machine shop did not charge me anything. Real nice guys.

I cut slots in the top so I could screw it in to the dropout/derailleur hanger, after boring it out to 12 mm diameter.

It fits like a glove. Actually, because it's threaded, and it screws into the derailleur hanger, it's more secure than the Rohloff reduction sleeve above which simply slides into the dropout.

The wheel/hub is now installed.

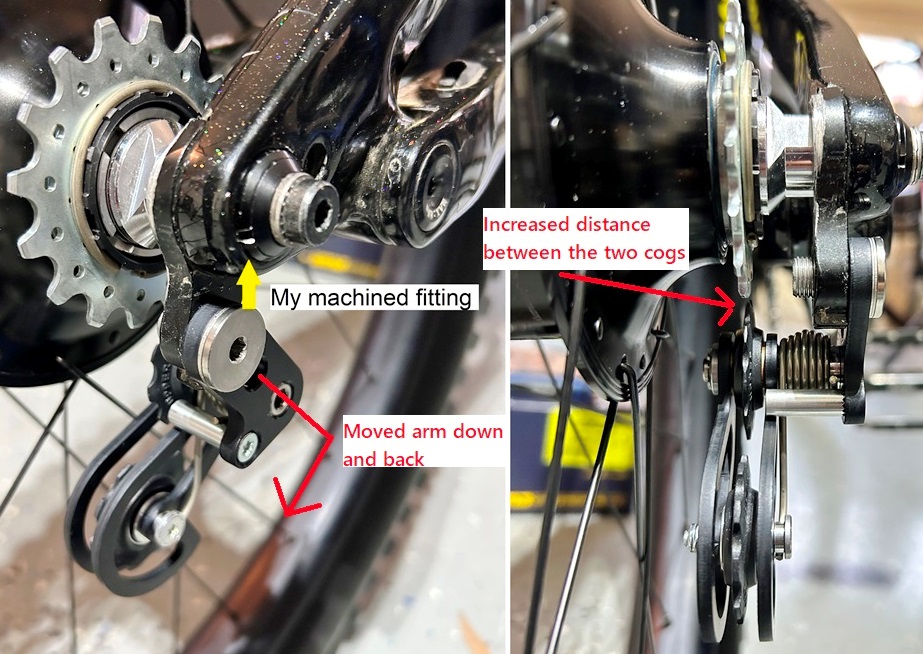

Installed the Downhill Chain Tensioner into the existing rear derailleur hanger.

4/25/23

Installed the shift cables into the shift mechanism. Pretty straightforward, the Rohloff video makes it easy.

Installed matching half-grip from SQLabs

Installed the chain, just like any other single speed chain with a chain tensioner.

Filled the hub with oil. Very simple 5 minute operation.

Changed the "Stop Decay" setting in the controller to "0". I want instant power cut off when I stop pedaling for shifting under load.

I may have to adjust the "Time of stop" down also, not sure how they will interact with each other.

See posts below from Smorgasbord and Gionnirocket with which I concur, after testing. "Stop Decay" and "Time of Stop" have no effect on the Ultra w/torque sensing

Rohloff A12 IGH install is complete! Yay!

Test drive tomorrow morning.

4/26/23

On my short test drive, it was an amazing feeling of being able to get into any gear, near instantaneously, without the traditional peculiarities of the Cog/Cassette system. I can go from gear 1 to gear 14 in a second, or 14-1. To shift under load, I pause for a millisecond with my pedals in the 12 and 6 O'clock position, click and done. It's a fast change, and it really is near instantaneous. Perfect shifting everytime, click and forget.

I'm going to give it a long test ride today under strenuous conditions and will report back.

4/27/23 - Last Installation piece, The Chain Guide

Haven't done that yet. I never had one when I was running a derailleur system, I did lose the chain every now and then when my rear suspension was bounced hard at speed. I will ride it for a few days to see how it performs without. I will install it in about a week. Not quite as simple on the carbon fiber frame as with an aluminum frame.

4/28/23 - Still no action from Rohloff or the Dealer, Peter White Cycles on the missing sleeve adapter for the right hand drop out. See entry above on 4/23. I emailed them both on 4/23, and called Peter White Cycles and spoke to him on Monday, 4/24. Spoke to him again on 4/27 and he said he has not heard from Rohloff. If I had not machined my own sleeve fitting, I'd be livid right now.

4/30/23 Peter White Cycles called to tell me that Rohloff will be sending me the adapter sleeve. The reason it takes so long is because Rohloff has only one representative that is the English speaking liaison for all of the English speaking dealers around the world, and part of his job is to attend Bike Shows too. I'm not too worried since my machined adapter is working fine, and I will be using that instead of the Rohloff version. Just curious to see how long they take to respond.

5/3/23 Received an apologetic letter from Stewart (Sales Manager for U.S.) at Rohloff regarding the missing part and untimely response. He assured me that the part is en route.

It's been cold and rainy for the last few days, No bike test riding for the last few days.

5/8/23

I've ridden my bike with the Rohloff hub now many hours. Particularly I took it out on some rugged MTB trails. Lots of rocks, roots, hills, etc. It performed far better than I would have hoped for. The uphill gearing is perfect, and the benefit of being able to access any gear instantly is nice when you get stopped on a hill and need to shift a few gears and restart your uphill climb. The hub operates super smooth, and takes the power of the Bafang Ultra Mag in stride. The shifting operation is smoother and more efficient than the cog/derailleur system. I am very impressed, at least in the short run. Shifting under load is not problem. The process is now subconscious and very fast. The hub is a real pleasure to drive.

5/16/23 - Email arrived from Peter White Cycles that my missing part (adapter sleeve above)) had arrived and they shipped it out via 1st. Class Mail.

5/20/23 - Well, after 26 days, the missing adapter sleeve for the right hand drop out finally arrived. I will store it in my toolbox for who knows what. They even sent me a Rohloff sticker for my troubles! My adapter (4/23 above) that I had custom machined is superior because it threads into the derailleur hanger and is theoretically more secure. Thank the Lord I was able to "MacGyver" the fix. I would have been pretty angry about the delay in getting the part. To be fair, I also did not press the dealer or Rohloff for speed because I was already up and running and I let them know that.

5/20/23 - I've ridden on some pretty aggressive MTB trails and bounced the rear suspension quite a lot under speed. I have not lost the chain in circumstances where I did lose the chain in the past with my cog/derailleur system. If this continues I may not install the chain guard.

6/19/23 - Recently I have lost the chain a few times when the rear end is bounced really hard. When I installed the Downhill Chain Tensioner I realized it was not as tight as I would have preferred. I may need to remove one or two more links from the chain, to keep the tensioner tight. I may also need to install the Chain Guide which I purchased but did not install yet. I'll try removing the links first and see how it behaves.

6/23/23

Removed two links from the chain. I was also getting some "chatter" from the Down Hill Tensioner when running downhill on rocky mtb trails. I read that it may be caused by the top tensioner guide wheel hitting the hub cog. I adjusted the downhill chain tensioner swing arm to give a few more mm of distance. Original Rohloff specs have the guide wheel and cog pretty close.

6/30/23 -So far so good. After removing two chain links, and moving the chain ring arm back, I've not dropped the chain.... yet.

7/29/23 - Dropped the chain a few more times again. Removed two more links about two weeks ago, the chain is much tighter. Does not come off at all.

8/28/23 - Still have not dropped the chain since removing the last two links. Looks like I will not be installing a chain guide.

8/28/23 - Did my first oil change. The oil goes in clear, here is how it looks after 3500KM of use. This first change is supposed remove the particulate fine filings that accumulate during the break-in period. Supposed to shift and run progressively smoother moving forward, but is has been running smooth from the beginning.

8/3/23 - Broke my Downhill Chain tensioner, broke my chain, and lost my rear cog snap ring.

Riding yesterday in the grass on a hill, felt like I hit an object in the rear, not sure what it was (rock, stump, stick), if anything. My crank started spinning freely with no effect on the rear drive, heard a grinding noise in the rear, thought it was the internal gears, then lost the chain. The snap ring that holds the cog in place had come off, the chain apparently broke, got wrapped into the chain tensioner, chain tensioner broke off. Not sure what the cause was. Did I hit something and snap the chain tensioner? Did the snap ring come off first? Did the chain break and cause everything? Most likely had a chain break that seized up in the chain tensioner and put lateral force on the cog causing the snap ring to pop off. I've had a similar experience on my BBSHD and Bafang Ultra where the chain broke, snagged the derailleur and destroyed it. New Downhill Tensioner will be here in 4 days. Luckily, my backup plan (wife's new Frey Savannah) will keep me riding until I make the repair.

12/22/23 - General Update

I cannot believe how nice this Rohloff hub is, especially coupled to a Bafang Ultra.

It runs flawlessly, no adjustments, no problems. Very refined piece of German engineering.

No more dropped chains since I removed two more chain links in July (see above).

6/20/24 - Update

A few months ago I replaced the 16T rear cog with a 13T rear cog to achieve a more desired gear ratio. The change was nice, more top with some still serious climbing ability.

After a few months of riding, the 13T cog broke in two. I surmise that becuase it is made of much less steel than the 16T cog, it could not handle the continued stress of the Bafang Ultra. I'm going to move to a 50T chainring intead of my 40T chainring.

THE KIT

The kit contains:

Rohloff A14 Speedhub. The A14 is specifically designed for a Thru-Axle rear hub and must be specifically authorized by Rohloff for your specific bike.

Custom Drop Out Axle Adapters

Twist Shifter, cables, and External Gear Housing

Axle Plate (torque arm)

PM Bone (to attach the torque arm to brake post mounts)

Oil for first install. The Rohloff is oil filled.

Rohloff oil change and cleaning kit. (change oil every 3,100 miles)

Downhill Chain Tensioner (for rear suspension bikes)

16T rear cog - sized (as per Rohloff) in relation to the 40T front chain ring, factoring the 160NM crank output of the Ultra Mag mid drive.

203mm 4-hole brake disc

36 - Sapam Race, pre-cut spokes and nipples (4 extra).

Additional Purchases for the install.

Chain Guide

27.5" Velocity Dually MTB Rim

KMC 8-Speed EBike chain designed for mid-drives. (single speed chains will not fit the Downhill Tensioner.)

SQLabs grips with short right grip for twist shifter.

Rohloff manufactures several IGH Speedhub 14's to accommodate differing drop outs. There is the E14 Electric shift versions, thru-axles, solid threaded axles, Quick Release axles, Fat Hubs, and hubs from 135mm O.L.D. to 197mm.

If you are installing the hub on a Thru Axle bike (like mine), Rohloff will not sell you a hub unless you use their special measuring kit and take specific measurements of your dropouts, and their thickness. Once you take the measurements, you record them via their online form along with the serial number of your bike. The Rohloff engineer will check your measurements, and if everything checks out, they will authorize a Rohloff dealer to sell you the A14 along with adapters specific to your dropouts. The measuring kit cost $350.00, and they will refund you your money once you send the kit back whether you purchase a hub or not. I had a devil of a time finding a dealer with a kit. All of the local dealers/distributors and service centers said their kits were out on loan, and they had no idea when they would be returned, or they did not stock the kit. I finally contacted Rohloff in Germany and they put me in touch with Peter White of Peter White Cycles. He had a kit and sent it promptly. I took the measurements and sent my results to Rohloff. Two weeks later their engineer contacted me and said something wasn't right. He asked me to measure again twice, and resend the measurements. It turns out their instructions said to "measure the dropouts without any additional components". I took that to mean without the derailleur hanger. Turns out I was wrong, and once we cleared that up, the measurements came back fine and, another week later, Rohloff gave me authorization to order the hub through the dealer. I returned the measuring kit and received a credit on my speedhub order. Peter White Cycles has been very helpful.

The Measuring Kit

My Bike: Luna Z1 Ultra Mag, Carbon Fiber.

From Rohloff:

"If you are ever unfortunate enough to have a SPEEDHUB stolen, then please inform us of this so we can flag the serial number as such. Nearly every SPEEDHUB returns to our service department at some time for servicing or conversion work. The relevant authorities will be informed if hubs arrive where the serial number is flagged as stolen. We have to date managed to return approximately 50% of all stolen hubs to their rightful owners."

4/21/23 - Wheel Lacing

FYI - The Rohloff installation manual and documentation are extensive.

I opted for a new rim, and laced the hub using 2X cross pattern recommended by Rohloff. The rim is a Velocity Dually 27.5" mid-fat/fat-race with a French nipple pattern. I sent the wheel ERD to Rohloff so they would cut the spokes with my order. Spokes are Sapim Race 1.8mm.

Rohloff recommends tensioning the spokes to 1,000N. I got as close as possible using my $25 spoke tension meter and the Park Tool Conversion Chart. Put a new tire on the rim, and took the wheel to my LBS and have theme equalize the spoke tension to 1,000N and compare my tension specs to theirs, and calibrate my tension meter for future reference.

"32/36 spoke SPEEDHUB wheels are typically far stronger than their derailleur counterparts. The strength is approximately equal to a 48 spoke tandem wheel of the same diameter.The SPEEDHUB spoke flanges are symmetrically positioned which places the rim directly in the center of the shell. Spokes on both sides of the wheel are therefore the same length and rest at the same angle which enables them to be tensioned equally." - Rohloff Manual

4/22/23 - Spokes Tensioned at local LBS

Installed the tire on the rim, which I taped for tubeless. Filled it with sealant, inflated it, and took it to my local TREK Bike store to have spokes tensioned to 1,000N. The guys at the store were very interested in my Rohloff hub. They'd heard about them but had no real working experience with them. The wheel builder complimented me on the build, apparently my $25.00 spoke tension meter pictured above was calibrated right on target. My spokes were tensioned well within an acceptable margin of error. No need for adjustments.

4/23/23

- Installed Twist Shifter

- Routed shifter cables.

- Removed Bafang Ultra motor, opened and checked the grease level and condition.

The twist shifter is pretty easy to install. Rohloff has a Youtube video and simple written instructions. Piece of cake.

I decided to route my cables inside the down tube. I removed the battery locking mechanism, brackets that secured the existing cables in the downtube, removed the Bafang motor, and routed the cables behind the battery, behind the motor, and out the rear suspension opening in the frame. The shifter cables will run neatly under the left hand chainstay using existing zip tie anchors.

Checked Motor Grease while I'm here:

Back in July 22', after about 600 miles on my bike, I decided to check the factory grease. I found it to be paltry at best. The motor was a considerably noisier than my existing Luna/Bafang BBSHD which seems to run nearly silent. In July 22 I installed Corn Head grease. See my thread here Corn Head Grease Install. Today, opened the motor after 2,000 more miles and I was pleased, grease everywhere. The system is well lubed, and very quiet. I slathered a few more tablespoons of grease and closed the motor.

6:00 PM A glass of cabernet, I'm ready to install the wheel and hook up the shift cables to the shift mechanism.

Except there is a glitch:

The left hand axle adapter is OK. The right hand axle adapter is OK, but either Rohloff or the dealer forgot to include the right hand (sprocket side) Reduction Sleeve below. The sleeve is Yellow in the diagram, but it comes in black. I emailed Rohloff and the dealer. I'll call them in the morning. Hopefully it won't take too long to get one...

Tasks Remaining:

- Mount wheel

- Install shift cables into shift mechanism.

- Install Downhill Chain Tensioner

- Install chain

- Install hub oil

- Test ride

4/24/23 - Machined my own adapter while I wait for Rohloff.

I figure that Rohloff and the dealer will take at least a week to get me the correct right side dropout reduction sleeve (above Yellow). I decided I cannot wait. The right hand drop out of the Luna Z1 has a threaded insert that slides into the dropout and screws into the derailleur hanger on the opposite side of the dropout. It's threaded on the inside too, to anchor the thru-axle. I took the insert to a machine shop and they drilled out the inner threads to a 12mm smooth bore, which is the diameter of the Rohloff supplied right hand axle adapter above. Screwed it back into the dropout, and slid the Rohloff axle adapter into the fitting. It fits perfectly. - Problem solved. - The Machine shop did not charge me anything. Real nice guys.

I cut slots in the top so I could screw it in to the dropout/derailleur hanger, after boring it out to 12 mm diameter.

It fits like a glove. Actually, because it's threaded, and it screws into the derailleur hanger, it's more secure than the Rohloff reduction sleeve above which simply slides into the dropout.

The wheel/hub is now installed.

Installed the Downhill Chain Tensioner into the existing rear derailleur hanger.

4/25/23

Installed the shift cables into the shift mechanism. Pretty straightforward, the Rohloff video makes it easy.

Installed matching half-grip from SQLabs

Installed the chain, just like any other single speed chain with a chain tensioner.

Filled the hub with oil. Very simple 5 minute operation.

See posts below from Smorgasbord and Gionnirocket with which I concur, after testing. "Stop Decay" and "Time of Stop" have no effect on the Ultra w/torque sensing

Rohloff A12 IGH install is complete! Yay!

Test drive tomorrow morning.

4/26/23

On my short test drive, it was an amazing feeling of being able to get into any gear, near instantaneously, without the traditional peculiarities of the Cog/Cassette system. I can go from gear 1 to gear 14 in a second, or 14-1. To shift under load, I pause for a millisecond with my pedals in the 12 and 6 O'clock position, click and done. It's a fast change, and it really is near instantaneous. Perfect shifting everytime, click and forget.

I'm going to give it a long test ride today under strenuous conditions and will report back.

4/27/23 - Last Installation piece, The Chain Guide

Haven't done that yet. I never had one when I was running a derailleur system, I did lose the chain every now and then when my rear suspension was bounced hard at speed. I will ride it for a few days to see how it performs without. I will install it in about a week. Not quite as simple on the carbon fiber frame as with an aluminum frame.

4/28/23 - Still no action from Rohloff or the Dealer, Peter White Cycles on the missing sleeve adapter for the right hand drop out. See entry above on 4/23. I emailed them both on 4/23, and called Peter White Cycles and spoke to him on Monday, 4/24. Spoke to him again on 4/27 and he said he has not heard from Rohloff. If I had not machined my own sleeve fitting, I'd be livid right now.

4/30/23 Peter White Cycles called to tell me that Rohloff will be sending me the adapter sleeve. The reason it takes so long is because Rohloff has only one representative that is the English speaking liaison for all of the English speaking dealers around the world, and part of his job is to attend Bike Shows too. I'm not too worried since my machined adapter is working fine, and I will be using that instead of the Rohloff version. Just curious to see how long they take to respond.

5/3/23 Received an apologetic letter from Stewart (Sales Manager for U.S.) at Rohloff regarding the missing part and untimely response. He assured me that the part is en route.

It's been cold and rainy for the last few days, No bike test riding for the last few days.

5/8/23

I've ridden my bike with the Rohloff hub now many hours. Particularly I took it out on some rugged MTB trails. Lots of rocks, roots, hills, etc. It performed far better than I would have hoped for. The uphill gearing is perfect, and the benefit of being able to access any gear instantly is nice when you get stopped on a hill and need to shift a few gears and restart your uphill climb. The hub operates super smooth, and takes the power of the Bafang Ultra Mag in stride. The shifting operation is smoother and more efficient than the cog/derailleur system. I am very impressed, at least in the short run. Shifting under load is not problem. The process is now subconscious and very fast. The hub is a real pleasure to drive.

5/16/23 - Email arrived from Peter White Cycles that my missing part (adapter sleeve above)) had arrived and they shipped it out via 1st. Class Mail.

5/20/23 - Well, after 26 days, the missing adapter sleeve for the right hand drop out finally arrived. I will store it in my toolbox for who knows what. They even sent me a Rohloff sticker for my troubles! My adapter (4/23 above) that I had custom machined is superior because it threads into the derailleur hanger and is theoretically more secure. Thank the Lord I was able to "MacGyver" the fix. I would have been pretty angry about the delay in getting the part. To be fair, I also did not press the dealer or Rohloff for speed because I was already up and running and I let them know that.

5/20/23 - I've ridden on some pretty aggressive MTB trails and bounced the rear suspension quite a lot under speed. I have not lost the chain in circumstances where I did lose the chain in the past with my cog/derailleur system. If this continues I may not install the chain guard.

6/19/23 - Recently I have lost the chain a few times when the rear end is bounced really hard. When I installed the Downhill Chain Tensioner I realized it was not as tight as I would have preferred. I may need to remove one or two more links from the chain, to keep the tensioner tight. I may also need to install the Chain Guide which I purchased but did not install yet. I'll try removing the links first and see how it behaves.

6/23/23

Removed two links from the chain. I was also getting some "chatter" from the Down Hill Tensioner when running downhill on rocky mtb trails. I read that it may be caused by the top tensioner guide wheel hitting the hub cog. I adjusted the downhill chain tensioner swing arm to give a few more mm of distance. Original Rohloff specs have the guide wheel and cog pretty close.

6/30/23 -So far so good. After removing two chain links, and moving the chain ring arm back, I've not dropped the chain.... yet.

7/29/23 - Dropped the chain a few more times again. Removed two more links about two weeks ago, the chain is much tighter. Does not come off at all.

8/28/23 - Still have not dropped the chain since removing the last two links. Looks like I will not be installing a chain guide.

8/28/23 - Did my first oil change. The oil goes in clear, here is how it looks after 3500KM of use. This first change is supposed remove the particulate fine filings that accumulate during the break-in period. Supposed to shift and run progressively smoother moving forward, but is has been running smooth from the beginning.

8/3/23 - Broke my Downhill Chain tensioner, broke my chain, and lost my rear cog snap ring.

Riding yesterday in the grass on a hill, felt like I hit an object in the rear, not sure what it was (rock, stump, stick), if anything. My crank started spinning freely with no effect on the rear drive, heard a grinding noise in the rear, thought it was the internal gears, then lost the chain. The snap ring that holds the cog in place had come off, the chain apparently broke, got wrapped into the chain tensioner, chain tensioner broke off. Not sure what the cause was. Did I hit something and snap the chain tensioner? Did the snap ring come off first? Did the chain break and cause everything? Most likely had a chain break that seized up in the chain tensioner and put lateral force on the cog causing the snap ring to pop off. I've had a similar experience on my BBSHD and Bafang Ultra where the chain broke, snagged the derailleur and destroyed it. New Downhill Tensioner will be here in 4 days. Luckily, my backup plan (wife's new Frey Savannah) will keep me riding until I make the repair.

12/22/23 - General Update

I cannot believe how nice this Rohloff hub is, especially coupled to a Bafang Ultra.

It runs flawlessly, no adjustments, no problems. Very refined piece of German engineering.

No more dropped chains since I removed two more chain links in July (see above).

6/20/24 - Update

A few months ago I replaced the 16T rear cog with a 13T rear cog to achieve a more desired gear ratio. The change was nice, more top with some still serious climbing ability.

After a few months of riding, the 13T cog broke in two. I surmise that becuase it is made of much less steel than the 16T cog, it could not handle the continued stress of the Bafang Ultra. I'm going to move to a 50T chainring intead of my 40T chainring.

Attachments

Last edited: