psychoanalyst

Member

Hello All,

Not strictly an eBike question, but wasn't sure where to post this. Please do let me know if there is different forum better suited to this question.

I got sick and tired of not having a dedicated stand for fixes on my Stromer ST1. Simple things like fixing flats, especially on the rear tire became a massive massive pain. And flipping the bike to make the tube replacements easier pretty much meant that I also had to perform a brake bleed. So, long story short, I just purchased the Park Tools bench mount stand from my friend who gave me a sweet deal on it. However, I wonder if I could install it on the wall instead (I know I know that there is a dedicated wall mount stand, but given the price of the wall mount and what I got the bench mount for, my choice was made) ?

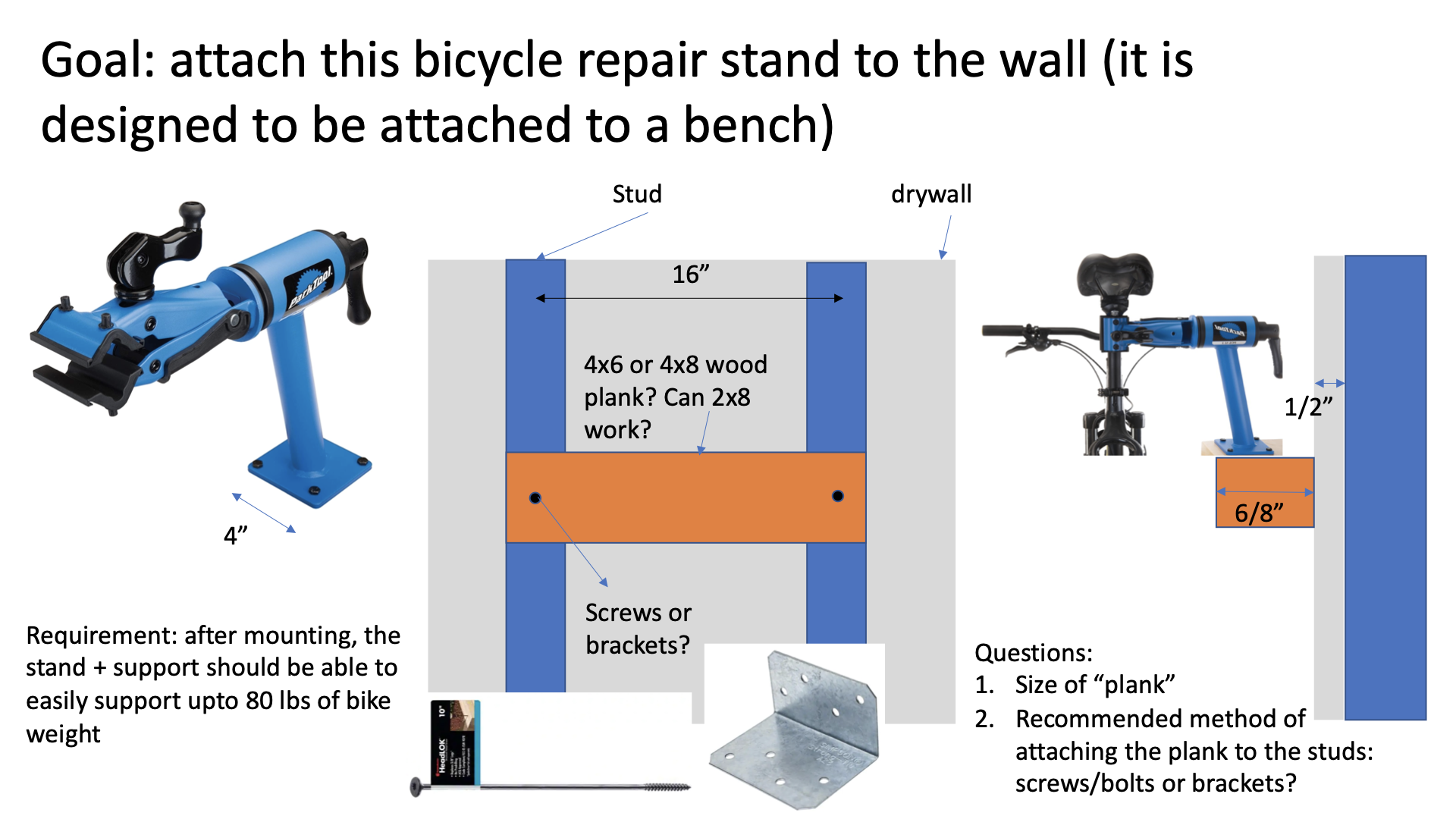

I made some plans which I have outlined below. And I am looking for advice on whether or not my plans make sense. My main questions:

1. What "plank" size would you recommend? I need need at least 5-6" on the flat surface where the stand would be mounted. So quite a few choices: 2x6, 2x8, 4x6, 4x8 etc. Would all of these work? Any reason why a 2x6 won't be sufficient for the job?

2. Recommended method of attaching the "plank" to the wall studs: I can use really long fasteners or I could go with corner brackets. Any advantages of one over the other?

Many thanks!

Avi

Not strictly an eBike question, but wasn't sure where to post this. Please do let me know if there is different forum better suited to this question.

I got sick and tired of not having a dedicated stand for fixes on my Stromer ST1. Simple things like fixing flats, especially on the rear tire became a massive massive pain. And flipping the bike to make the tube replacements easier pretty much meant that I also had to perform a brake bleed. So, long story short, I just purchased the Park Tools bench mount stand from my friend who gave me a sweet deal on it. However, I wonder if I could install it on the wall instead (I know I know that there is a dedicated wall mount stand, but given the price of the wall mount and what I got the bench mount for, my choice was made) ?

I made some plans which I have outlined below. And I am looking for advice on whether or not my plans make sense. My main questions:

1. What "plank" size would you recommend? I need need at least 5-6" on the flat surface where the stand would be mounted. So quite a few choices: 2x6, 2x8, 4x6, 4x8 etc. Would all of these work? Any reason why a 2x6 won't be sufficient for the job?

2. Recommended method of attaching the "plank" to the wall studs: I can use really long fasteners or I could go with corner brackets. Any advantages of one over the other?

Many thanks!

Avi