Alright, finally the first serious problem with my Bafang m620 and Innotrace X1 3000W controller.

After about half a year of riding the motor become extremely loud with grinding sound and maintained free pedaling resistance. I rode it like that another half a year and motor got even worst, it started overheating quite quickly and eating the battery way faster than when it was new. It also sometimes had weird power losses events.

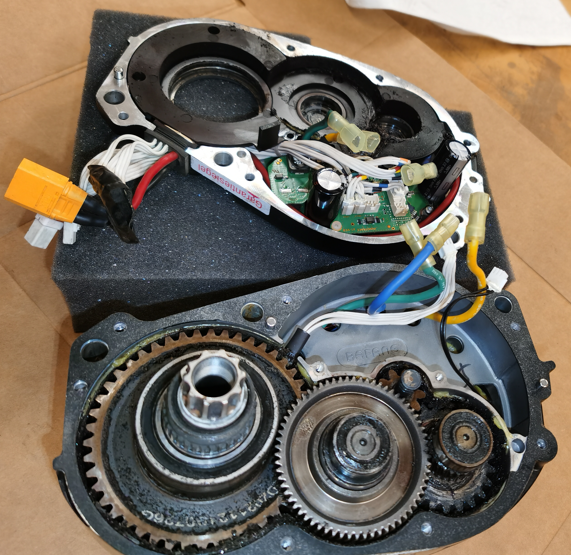

So I decided to open the motor and re grease it. When I opened the motor I found the motor has original yellow Bafang grease in it (I paid extra to Innotrace to re grease it with red Mobil grease and they did nothing! WTF! )

)

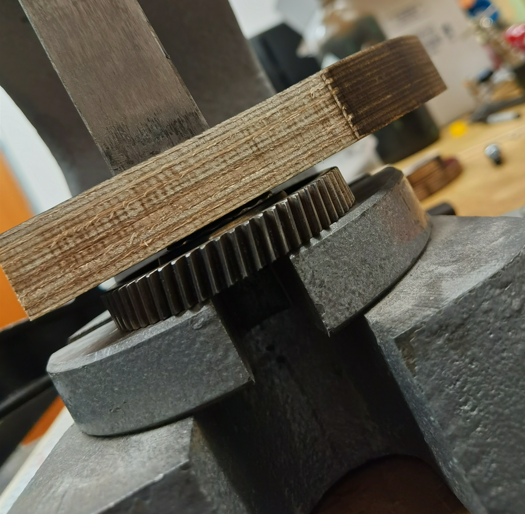

Anyway, I cleaned the motor from the old grease and gunk and inspected the gears and I found the middle gear with overrun clutch (one way bearing) moved on that bearing aside and started interfering with other gears also locking the one way bearing action (that was the source of the pedaling resistance because of now I had to crank the motor rotor too and overcome all that friction between the rubbing gears.)

So I pulled that gear off from the shaft and pressed the one way bearing back to in's original place

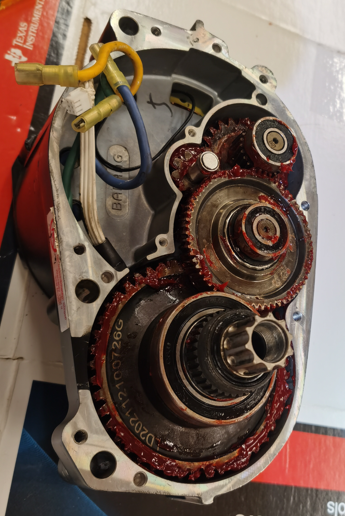

Then I put some fresh red Mobilgrease 28

Assembled everything back and the rode it. The motor worked fine for about 15 minutes, then after coasting a downhill section I started pedal it again and there was no pedal assist, motor just made a weirs sound for a second and stopped. Then it did not responded on throttle or pedaling after that and I pushed my bike for 2 hours home

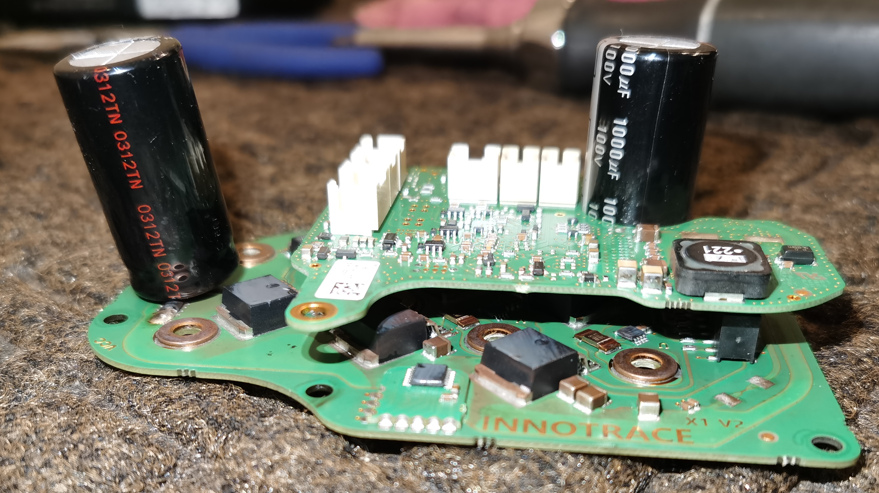

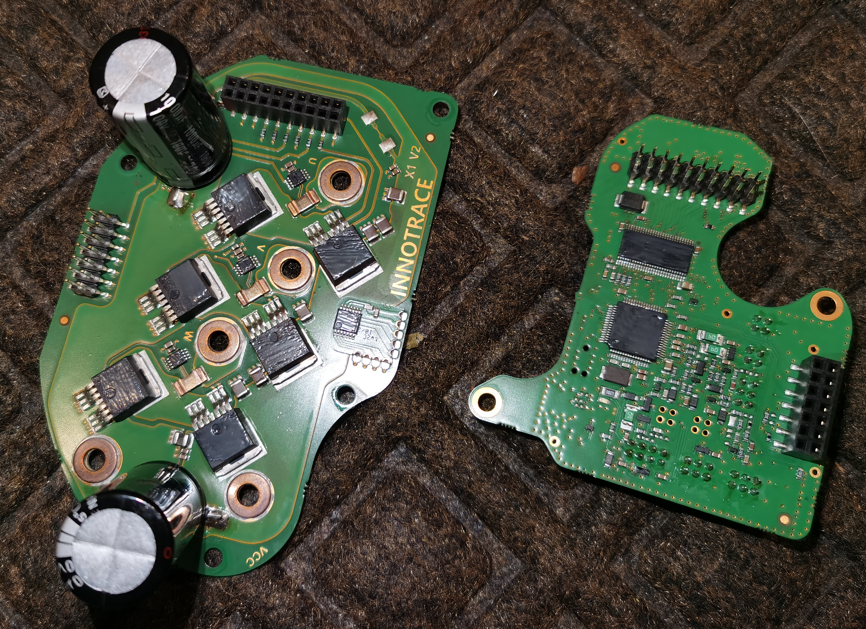

I disassembled the motor again and started inspecting the Innotrace X1 motor controller. I found nothing unusual, the controller looked fine.

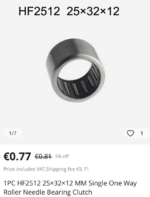

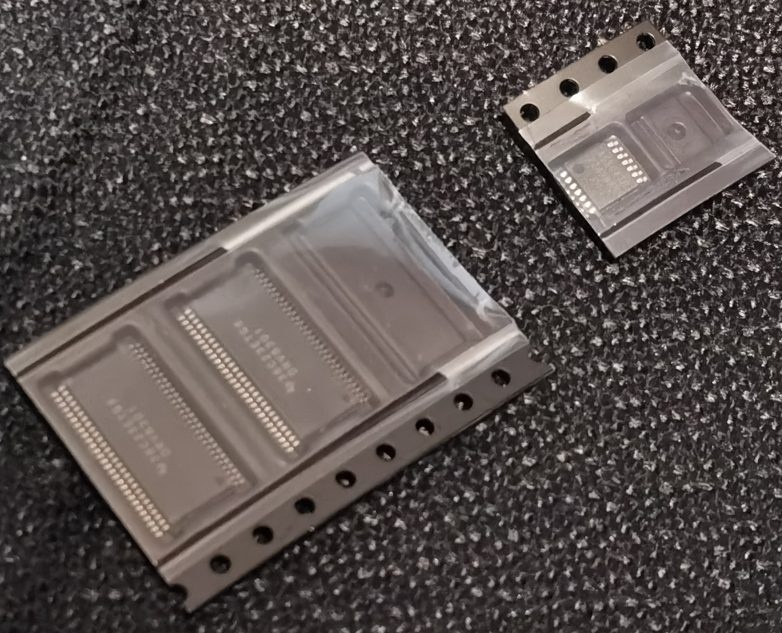

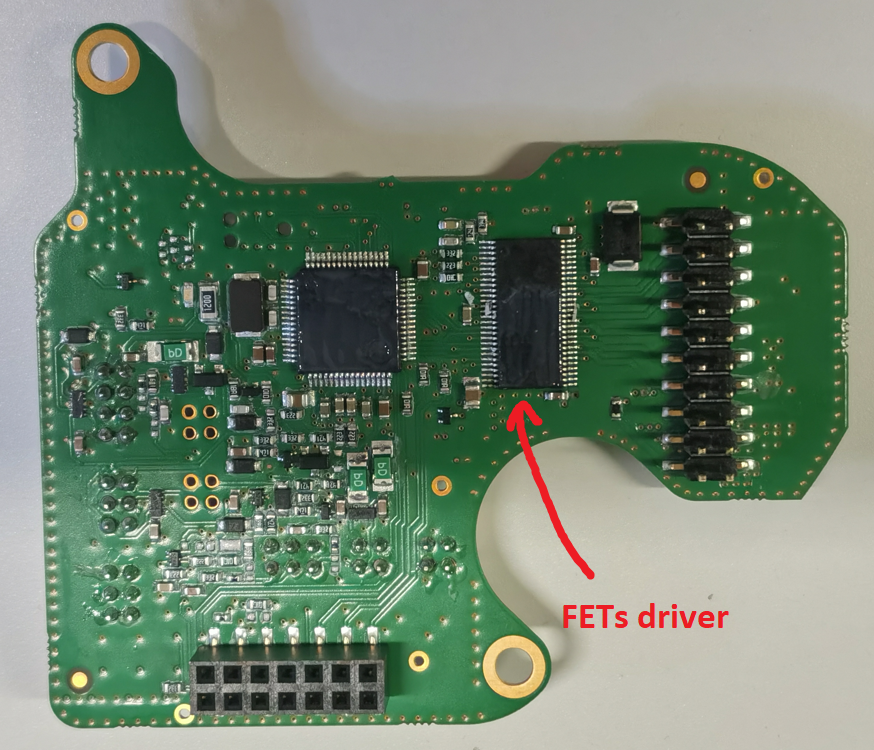

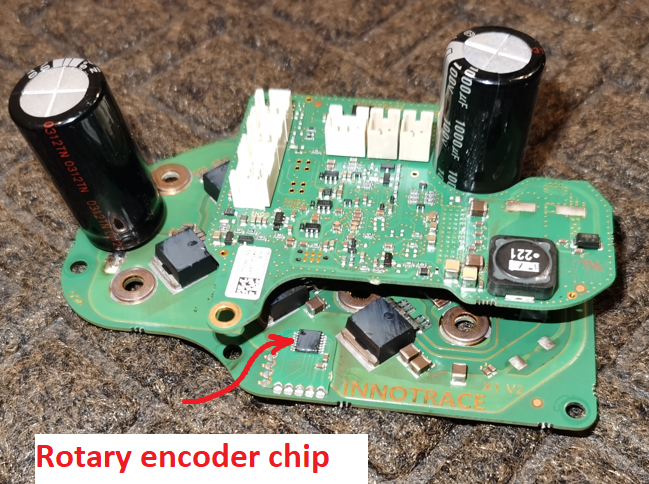

I checked the FETs resistance (Innotrace X1 uses Infineon Technologies IRFS7530-7P transistors, just like VESK 4 brushless motor controller) and they looked fine. So I decided to replace the FET driver chip (Innotrace X1 uses Texas Instruments DRV8301DCAR driver, just like VESK 4 brushless motor controller) and the rotary encoder chip ( Innotrace X1 uses ams-OSRAM USA INC. AS5047P-ATSM rotary encoder). I ordered the new chips from DigiKey

Then I replaced the FETs driver first

Then I assembled the motor back and it still did not work.

Then I replaced the rotary encoder chip

Assembled the motor back quickly without installing gears and plastic shroud and motor works now! So it was bad encoder chip!

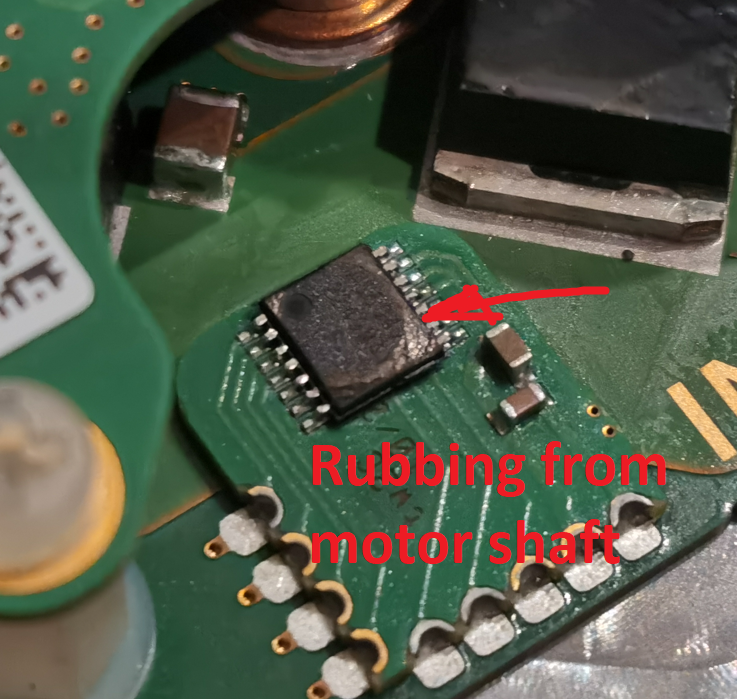

Then I disassembled the motor to put the gears and other stuff back and found rubbing marks on the new encoder surface from the motor magnet from the motor shaft! WTF is this s*it!

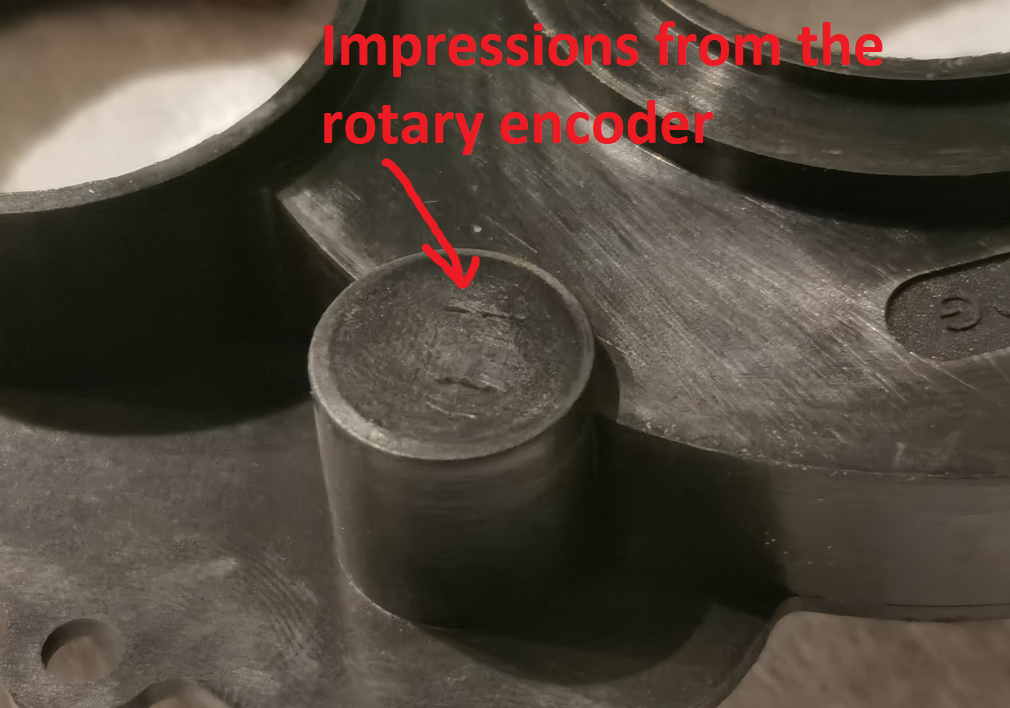

The magnet tip glued on the rotor shaft had rubbing marks too

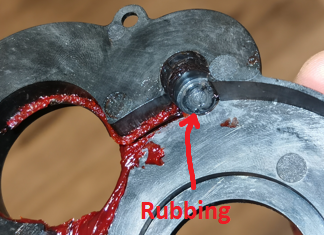

Then I took a close look on the plastic shroud which seats between the rotary encoder chip and the motor magnet on the shaft and found deep impression on the bottom of the shroud from the old rotary encoder. The inside of the shroud above the encoder spot has rubbing marks from the motor shaft too.

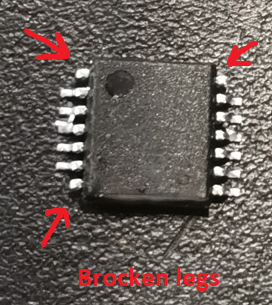

Then I took a close look on the old rotary encoder chip I removed and found 3 broken legs! This was the source of the motor stopped working.

So what happened is the plastic shroud was jammed between the motor shaft and the rotary encoder chip and all this time motor pushed the encoder chip causing the encoder to rock and heat up and over time the legs of the encoder cracked and lost connection with the board.

At this point I do not know why the motor shaft is so close to the rotary encoder. It is possible that the shaft drifted over time (because of the helical gear on the motor rotor maintains lateral force), or maybe I displaced the rotor shaft somehow when I disassembled the motor for cleaning and assembled it back (the shaft has about 1 mm lateral freeplay and it can cause the rotor shaft taps the plastic shroud and the rotary encoder chip), or maybe it is a design flaw because of the rotary encoder chip seats too close to the motor shaft, or maybe this is a Bafang assembly flaw and they glued the magnet and assembled the rotor the way it seats closer to the rotary encoder than it should be.

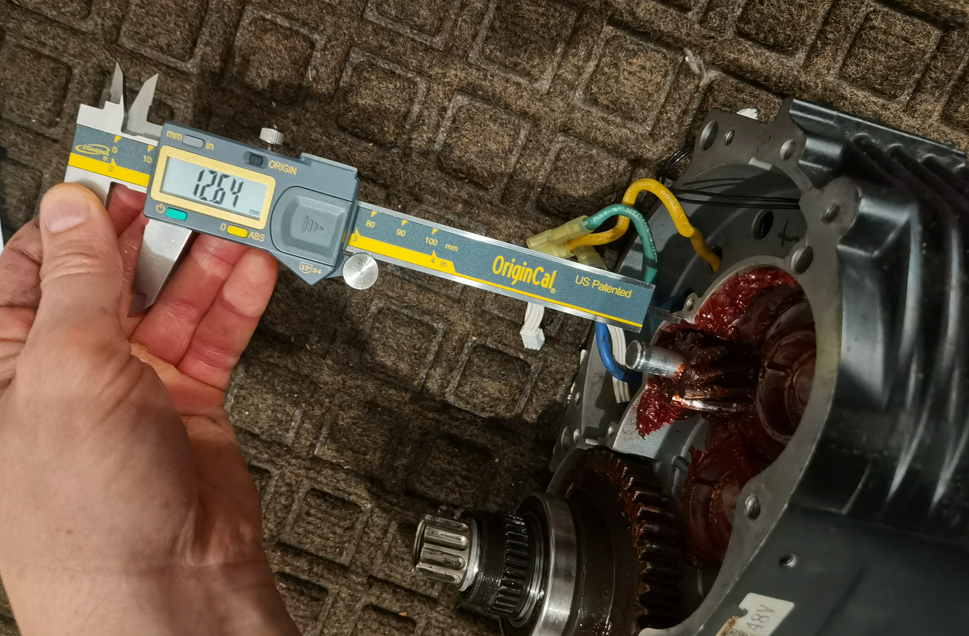

Anyway, I took some measurements and found the rotor shaft touches the rotary encoder indeed.

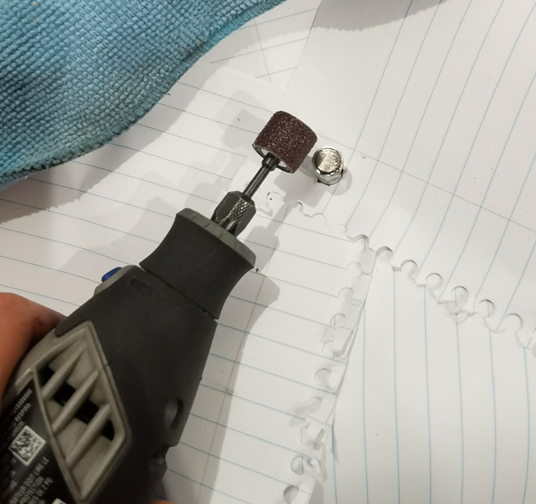

So I covered the motor internals and sanded the rotor shaft magnet down about 1 mm

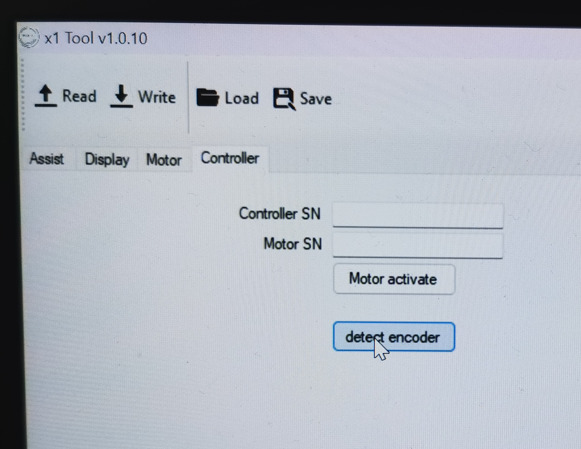

Then I assembled the motor back and calibrated the motor with new rotary encoder chip with bypassed X1 tool

Man, this motor works now better than new. No overheating, no grinding sound, no weird power loss and battery at the end of commute has maybe 25% more energy!

So if you have Innotrace X1 (Archon X1) motor controller keep an eye on the rotary encoder and spacing between the encoder and the motor magnet on the end of the rotor shaft. Also keep an eye on the middle gear because of 3000W combined with helical gear can displace that gear on the bearing and cause all sorts of problems.

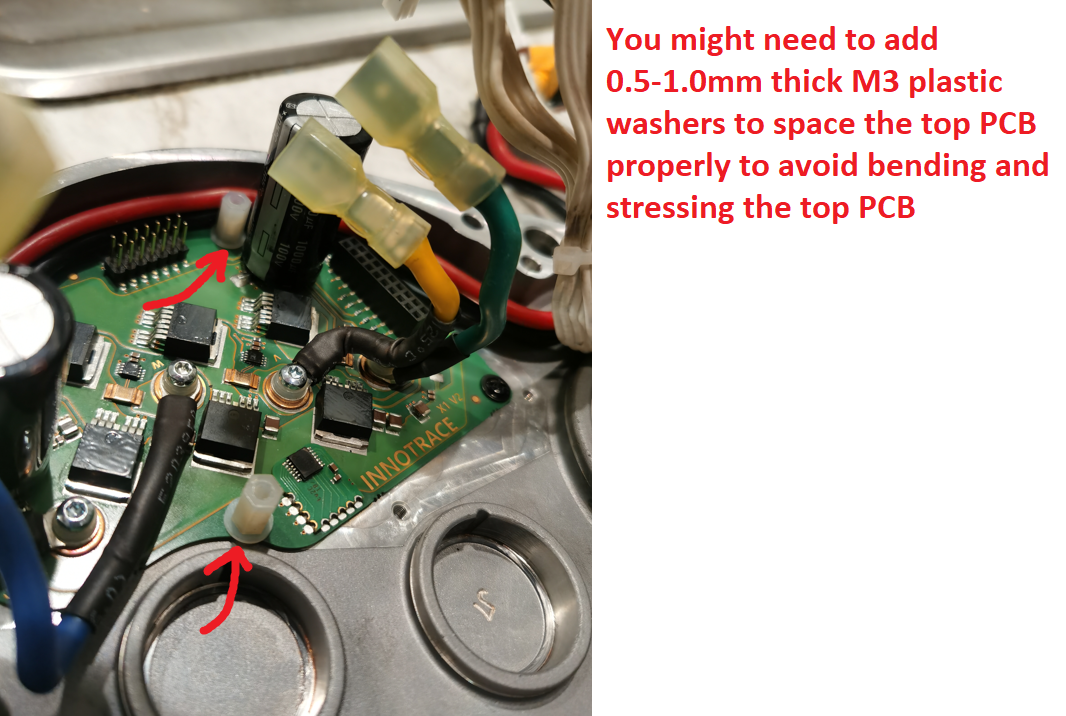

Also, if you are going to dig deep inside your Innotrace powered motor you might want to check how the top board of the controller sits on the bottom board on the plastic standoffs. Mine was bowed and required adding about 1mm thick M3 plastic washers to space the top board properly without bowing it.

After about half a year of riding the motor become extremely loud with grinding sound and maintained free pedaling resistance. I rode it like that another half a year and motor got even worst, it started overheating quite quickly and eating the battery way faster than when it was new. It also sometimes had weird power losses events.

So I decided to open the motor and re grease it. When I opened the motor I found the motor has original yellow Bafang grease in it (I paid extra to Innotrace to re grease it with red Mobil grease and they did nothing! WTF!

Anyway, I cleaned the motor from the old grease and gunk and inspected the gears and I found the middle gear with overrun clutch (one way bearing) moved on that bearing aside and started interfering with other gears also locking the one way bearing action (that was the source of the pedaling resistance because of now I had to crank the motor rotor too and overcome all that friction between the rubbing gears.)

So I pulled that gear off from the shaft and pressed the one way bearing back to in's original place

Then I put some fresh red Mobilgrease 28

Assembled everything back and the rode it. The motor worked fine for about 15 minutes, then after coasting a downhill section I started pedal it again and there was no pedal assist, motor just made a weirs sound for a second and stopped. Then it did not responded on throttle or pedaling after that and I pushed my bike for 2 hours home

I disassembled the motor again and started inspecting the Innotrace X1 motor controller. I found nothing unusual, the controller looked fine.

I checked the FETs resistance (Innotrace X1 uses Infineon Technologies IRFS7530-7P transistors, just like VESK 4 brushless motor controller) and they looked fine. So I decided to replace the FET driver chip (Innotrace X1 uses Texas Instruments DRV8301DCAR driver, just like VESK 4 brushless motor controller) and the rotary encoder chip ( Innotrace X1 uses ams-OSRAM USA INC. AS5047P-ATSM rotary encoder). I ordered the new chips from DigiKey

Then I replaced the FETs driver first

Then I assembled the motor back and it still did not work.

Then I replaced the rotary encoder chip

Assembled the motor back quickly without installing gears and plastic shroud and motor works now! So it was bad encoder chip!

Then I disassembled the motor to put the gears and other stuff back and found rubbing marks on the new encoder surface from the motor magnet from the motor shaft! WTF is this s*it!

The magnet tip glued on the rotor shaft had rubbing marks too

Then I took a close look on the plastic shroud which seats between the rotary encoder chip and the motor magnet on the shaft and found deep impression on the bottom of the shroud from the old rotary encoder. The inside of the shroud above the encoder spot has rubbing marks from the motor shaft too.

Then I took a close look on the old rotary encoder chip I removed and found 3 broken legs! This was the source of the motor stopped working.

So what happened is the plastic shroud was jammed between the motor shaft and the rotary encoder chip and all this time motor pushed the encoder chip causing the encoder to rock and heat up and over time the legs of the encoder cracked and lost connection with the board.

At this point I do not know why the motor shaft is so close to the rotary encoder. It is possible that the shaft drifted over time (because of the helical gear on the motor rotor maintains lateral force), or maybe I displaced the rotor shaft somehow when I disassembled the motor for cleaning and assembled it back (the shaft has about 1 mm lateral freeplay and it can cause the rotor shaft taps the plastic shroud and the rotary encoder chip), or maybe it is a design flaw because of the rotary encoder chip seats too close to the motor shaft, or maybe this is a Bafang assembly flaw and they glued the magnet and assembled the rotor the way it seats closer to the rotary encoder than it should be.

Anyway, I took some measurements and found the rotor shaft touches the rotary encoder indeed.

So I covered the motor internals and sanded the rotor shaft magnet down about 1 mm

Then I assembled the motor back and calibrated the motor with new rotary encoder chip with bypassed X1 tool

Man, this motor works now better than new. No overheating, no grinding sound, no weird power loss and battery at the end of commute has maybe 25% more energy!

So if you have Innotrace X1 (Archon X1) motor controller keep an eye on the rotary encoder and spacing between the encoder and the motor magnet on the end of the rotor shaft. Also keep an eye on the middle gear because of 3000W combined with helical gear can displace that gear on the bearing and cause all sorts of problems.

Also, if you are going to dig deep inside your Innotrace powered motor you might want to check how the top board of the controller sits on the bottom board on the plastic standoffs. Mine was bowed and required adding about 1mm thick M3 plastic washers to space the top board properly without bowing it.

Last edited: