Gionnirocket

Well-Known Unidentified Member

- Region

- USA

- City

- Y. O.

I've adapted a few chargers to use my DIY Charge adapter mentioned above by cutting the cable of the proprietary charger somewhere between it and the battery and soldering in a male and female of something more standard like an XLR or XT60. Then matching any other charger with the same.

Curious... take a look at the charger cable itself and see if the conductor count is printed on it. Usually in the same sentence as the AWG

My proprietary Zen battery has a similar but different 3 pin connector...

... but on inspection the cable is only a 2 conductor (2C) so the 3rd pin does nothing.

Same goes for the XLR chargers I've come across. So some of the information above is incorrect... at least in eBike applications

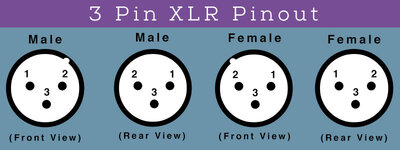

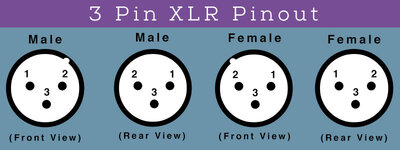

If using an XLR this is the correct Pin Out for a charger. The illustration given above is for audio applications.

Pin 1: Positive

Pin 2: Negative

Pin 3: n/a

The wires are typically 16awg or smaller... so the soldering is pretty easy. If you don't have any soldering skills, any electronics repair shop can

Curious... take a look at the charger cable itself and see if the conductor count is printed on it. Usually in the same sentence as the AWG

My proprietary Zen battery has a similar but different 3 pin connector...

... but on inspection the cable is only a 2 conductor (2C) so the 3rd pin does nothing.

Same goes for the XLR chargers I've come across. So some of the information above is incorrect... at least in eBike applications

If using an XLR this is the correct Pin Out for a charger. The illustration given above is for audio applications.

Pin 1: Positive

Pin 2: Negative

Pin 3: n/a

The wires are typically 16awg or smaller... so the soldering is pretty easy. If you don't have any soldering skills, any electronics repair shop can

Last edited: