JimVonBaden

Member

Not your typical ebike conversion here, but I thought it might interest some. Starting with a 1981 Vespa PX125, see photo and video:

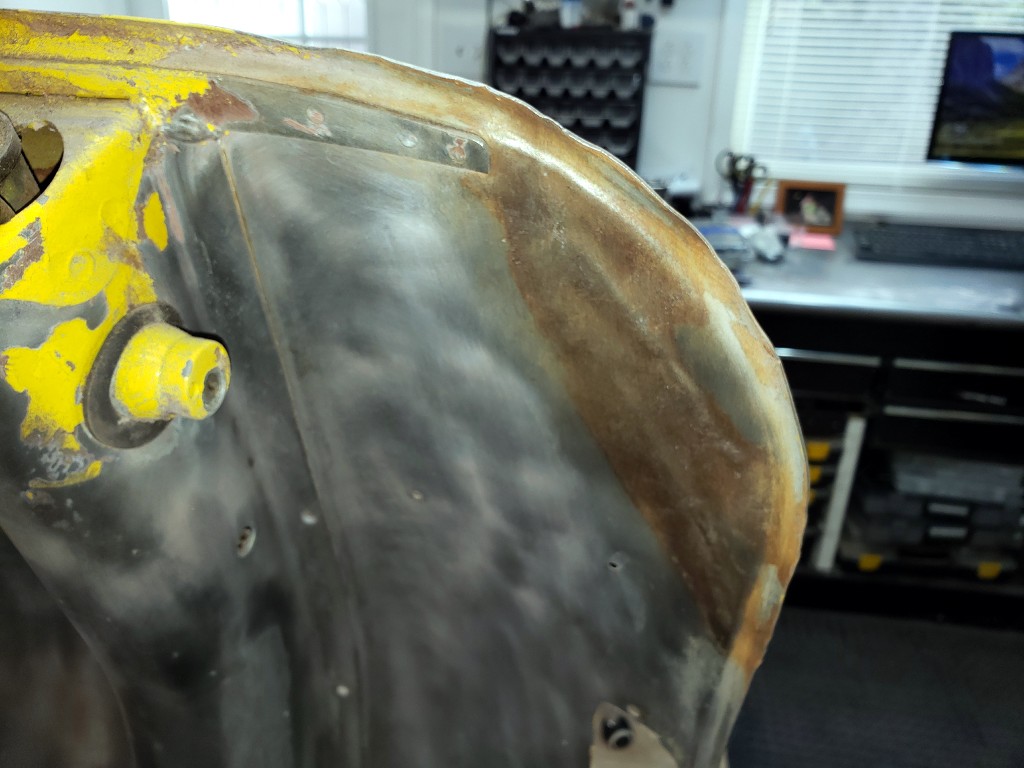

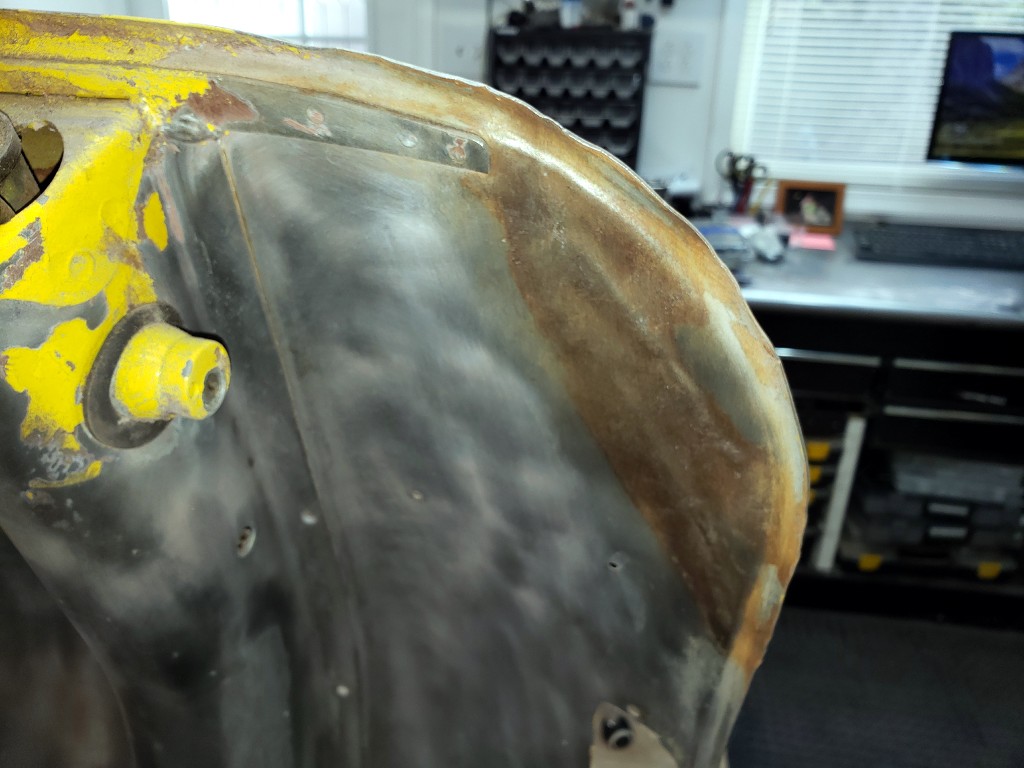

As you can see, it is not original enough to make a really nice restoration, though I originally planned to fit it up. Then I bought an ebike, and in studying mods and things I realized I have a perfect platform for conversion. I stripped it down to the bare chassis, and then stripped the paint and did the bodywork in prep for the conversion.

A little bodywork:

Paint will come after the final fab for the electric conversion.

Since the engine is the swingarm, I have to fab my own. After several mock-ups, this is what I have settled on:

I will weld it up after I receive the 4KW hub motor.

Speaking of parts, this is what I have ordered so far:

HWZ Series DC/DC Converter 96V to 12V

* ebike throttle

* Electric Motor QS Motor 10inch 205 4000W 72V 85km/h

* Brake kit

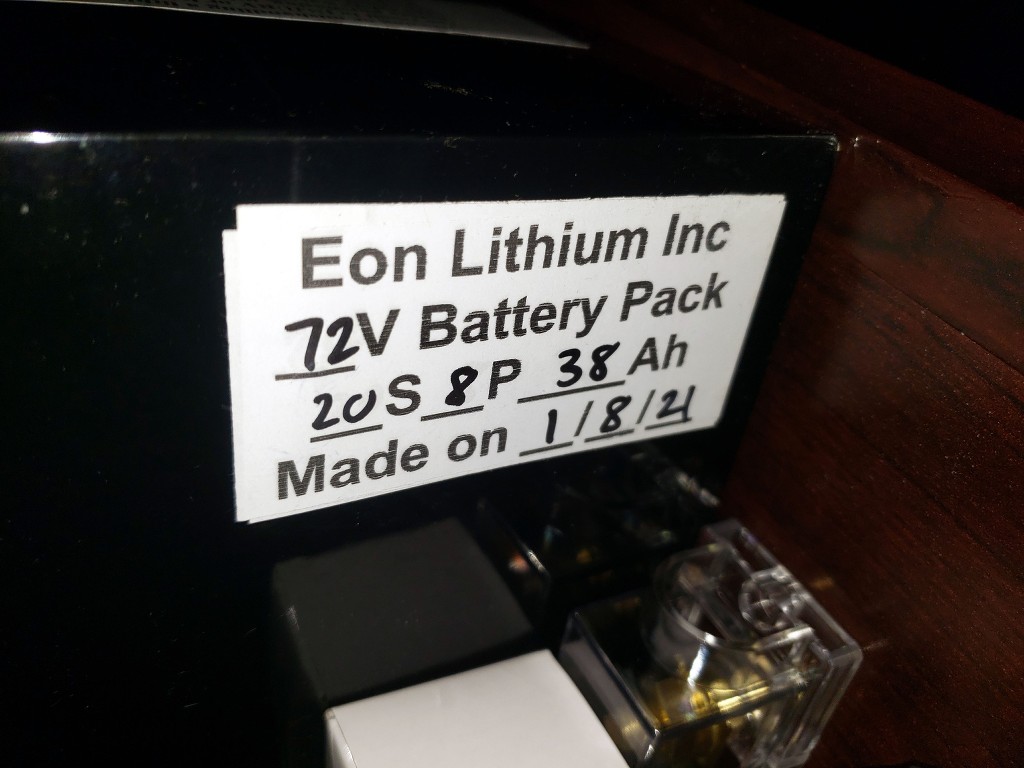

34ah 72V battery, custom made

Display, controller

J1 Cable

2*x CNL 500A Fuse

Emergency Contactor KEMG-125A 125A continuous

KBL/KEB J2 Cable

* Kelly Sine Wave Controller KLS7245H with IP66

While I wait for the slow boat, I will finish the bodywork and prep for paint, which will come after I finish the fabrication and install of the conversion.

As you can see, it is not original enough to make a really nice restoration, though I originally planned to fit it up. Then I bought an ebike, and in studying mods and things I realized I have a perfect platform for conversion. I stripped it down to the bare chassis, and then stripped the paint and did the bodywork in prep for the conversion.

A little bodywork:

Paint will come after the final fab for the electric conversion.

Since the engine is the swingarm, I have to fab my own. After several mock-ups, this is what I have settled on:

I will weld it up after I receive the 4KW hub motor.

Speaking of parts, this is what I have ordered so far:

HWZ Series DC/DC Converter 96V to 12V

* ebike throttle

* Electric Motor QS Motor 10inch 205 4000W 72V 85km/h

* Brake kit

34ah 72V battery, custom made

Display, controller

J1 Cable

2*x CNL 500A Fuse

Emergency Contactor KEMG-125A 125A continuous

KBL/KEB J2 Cable

* Kelly Sine Wave Controller KLS7245H with IP66

While I wait for the slow boat, I will finish the bodywork and prep for paint, which will come after I finish the fabrication and install of the conversion.