Trail Cruiser

Well-Known Member

I came across the internet about "ebike efficiency" from endless sphere

https://endless-sphere.com/w/index.php/EBike_Efficiency

and I thought it is worth sharing. The beauty of ebikes is there is a second source of motive power and that is your pedal power. It talks about the very basic principle about ebike motors. Here , it relates to a hub motor but the principle is still the same for the mid drives. The road speed on the chart is just changed to cadence on mid drives.

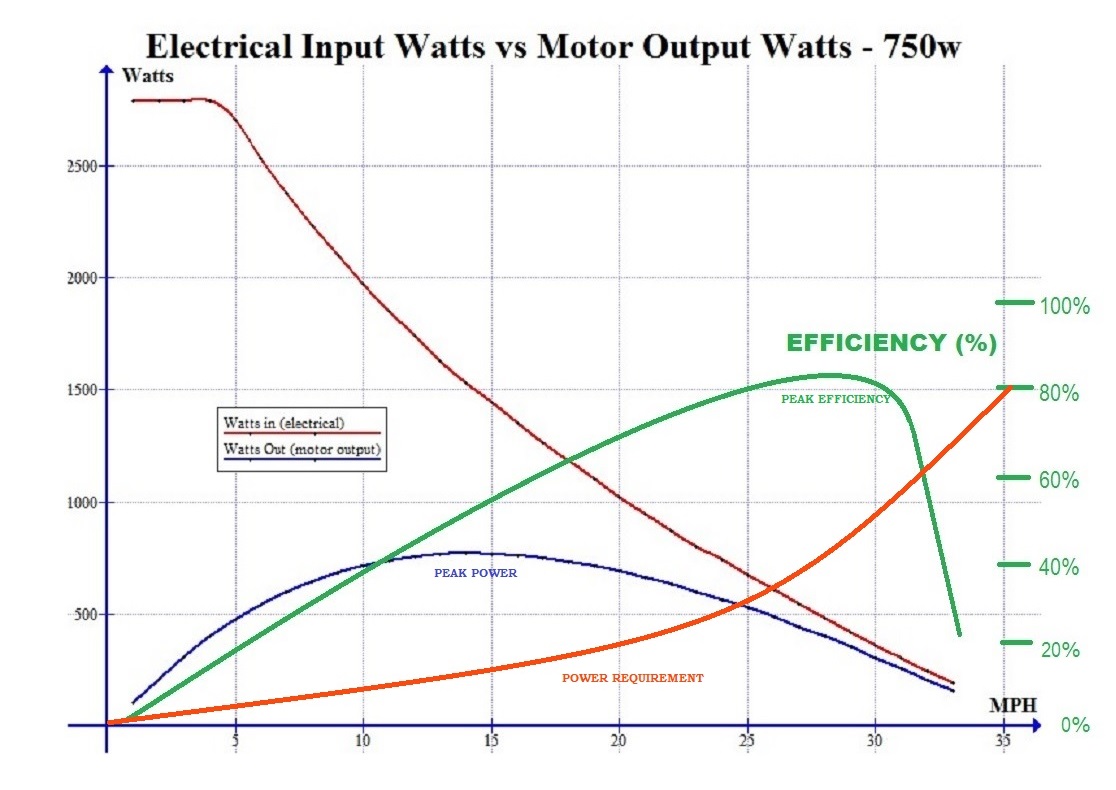

First, the power (watts) that comes out from the battery does not completely translates to actual watts to the wheels. There is a certain speed at which the conversion to mechanical power (motor efficiency) is highest.

(Link Removed - No Longer Exists)In this example, the motor efficiency is highest at speeds somewhere between 25-31 mph. The lower the speed, the less efficient is the motor. However, if we consider the power requirement at these speeds (as we will find out later), the actual window of efficiency is a very narrow 23-26 mph only since the motor is only strong enough up to 25-26 mph. The power curve slightly goes down to 600w at that speed while the power requirement quickly goes up to 600w at 25 mph and continue to go up above that speed.

Those watt meters on some ebike displays do not always represent the watts to the wheels but these are the wattage that came out from the battery. And if you are on the wrong speed, most of those watts are wasted as heat. Or if you are in the wrong cadence in the case of mid drives. Basing on the efficiency curve of the hub motor above, it appears that it is ideal for high speed commuting.

To minimize energy waste at lower speed, a controller is used to limit the max current.

(Link Removed - No Longer Exists)In the old days, simple resistors were used to control the current but these are very inefficient and obsolete and are now replaced by pulse width modulation controllers (PWM) with the use of metal–oxide–semiconductor field-effect transistors (MOSFET). The electrical current is then controlled to different levels. Example of this simple controller with different current settings at different assist levels is from a chart from Bafang mid drive (cadence is used at the x axis instead of road speed). The orange curve represents 100% (current decay is another user adjustable parameter in the Bafang controller)

https://electricbike-blog.com/2015/06/26/a-hackers-guide-to-programming-the-bbs02/

However, it is also important to know the power demand of an ebike at different speeds brought about by many factors and most especially the air resistance (aerodynamic drag), in order to further minimize power wastage when it is not needed and only apply power to when it is really needed.

(Link Removed - No Longer Exists)

You don't really need a lot of power at low speed but a simple controller's output is opposite (Cheap Chinese controllers). No wonder the cheap ebikes and ebike kits cannot reliably provide good battery mileage since you thought you are saving battery by going slower but you actually wasted a lot of power there. Most of the time, I notice that simple controllers feel "punchy" and tend to lurch ahead from a dead stop (great for showing off to friends) but once the ebike is already moving and you needed more assist, sometimes the power isn't there anymore, when you needed it the most.

Enter the Smart Controllers from the big players where more brain capacity is added to the controller's program in order to determine and match power requirement with the power output of the motor. And added measures are incorporated to cut the assist if the motor speed is at the inefficient range. This is made possible with the use of torque sensors and sophisticated program algorithms. An example of this is the "dynamic assist" from Juicedbikes.

http://juicedbikes.com.au/bikes/2017-crosscurrent/

As a general rule, the most sophisticated controllers take full advantage of the torque sensors and measure the rider's effort each millisecond (a thousandths of a second) and convert that into specific power to the motor based of the assist level. These are popularly called as "Proportional Assist" system.

It only goes to show that it's not only the motor efficiency that is important but how sophisticated the controllers are made. Not all controllers are created equal.

On mid drives, the gear reduction ratio is also set up so that the motor is most efficient at a cadence rate preferred by most cyclists (normal cadence range) .

https://www.electricbike.com/bosch-cannondale/

This principle in actual application made it possible for a small motor (mid drive) to achieve a very very impressive efficiency of 100 miles in 1 charge of the 500wh battery or 5 wh/mile!

https://electricbikereview.com/forums/threads/range-100-miles-giant-road-e.14617/#post-121767

This highest mileage potential is demonstrated by the small mid drive, but at a slower average speed (~15mph). The mid drives also has an advantage for the ability to climb very steep hills, as long as the gear ratio in the drive train is appropriate, but at the expense of even much slower, snail paced, speed (sometimes it feels like being pulled up by a winch!).

However, hub drives are not far behind in efficiency. Especially with increasing sophistication of the controllers and more efficient motor designs like the Maxon.

http://partir-en-vtt.com/fsb2/index.php?p=search&mode=author&id=52

https://electricbikereview.com/forums/threads/hub-vs-mid-drive-how-can-i-compare.14635/page-5

Hub drives are also more appropriate for high speed commuting, such as riding regularly at higher average speeds (above 23 mph) since the bicycle drive train at that higher crank output will wear out prematurely in less than a couple thousand miles. Or for transporting heavy loads such as the delivery ebikes.

There is still a bright future for efficient hub drives since, aside from the above mentioned strengths, hub drives are also very user friendly, easy gear shifting, durability, and is superior on stop and go city streets.

https://endless-sphere.com/w/index.php/EBike_Efficiency

and I thought it is worth sharing. The beauty of ebikes is there is a second source of motive power and that is your pedal power. It talks about the very basic principle about ebike motors. Here , it relates to a hub motor but the principle is still the same for the mid drives. The road speed on the chart is just changed to cadence on mid drives.

First, the power (watts) that comes out from the battery does not completely translates to actual watts to the wheels. There is a certain speed at which the conversion to mechanical power (motor efficiency) is highest.

(Link Removed - No Longer Exists)In this example, the motor efficiency is highest at speeds somewhere between 25-31 mph. The lower the speed, the less efficient is the motor. However, if we consider the power requirement at these speeds (as we will find out later), the actual window of efficiency is a very narrow 23-26 mph only since the motor is only strong enough up to 25-26 mph. The power curve slightly goes down to 600w at that speed while the power requirement quickly goes up to 600w at 25 mph and continue to go up above that speed.

Those watt meters on some ebike displays do not always represent the watts to the wheels but these are the wattage that came out from the battery. And if you are on the wrong speed, most of those watts are wasted as heat. Or if you are in the wrong cadence in the case of mid drives. Basing on the efficiency curve of the hub motor above, it appears that it is ideal for high speed commuting.

To minimize energy waste at lower speed, a controller is used to limit the max current.

(Link Removed - No Longer Exists)In the old days, simple resistors were used to control the current but these are very inefficient and obsolete and are now replaced by pulse width modulation controllers (PWM) with the use of metal–oxide–semiconductor field-effect transistors (MOSFET). The electrical current is then controlled to different levels. Example of this simple controller with different current settings at different assist levels is from a chart from Bafang mid drive (cadence is used at the x axis instead of road speed). The orange curve represents 100% (current decay is another user adjustable parameter in the Bafang controller)

https://electricbike-blog.com/2015/06/26/a-hackers-guide-to-programming-the-bbs02/

However, it is also important to know the power demand of an ebike at different speeds brought about by many factors and most especially the air resistance (aerodynamic drag), in order to further minimize power wastage when it is not needed and only apply power to when it is really needed.

(Link Removed - No Longer Exists)

You don't really need a lot of power at low speed but a simple controller's output is opposite (Cheap Chinese controllers). No wonder the cheap ebikes and ebike kits cannot reliably provide good battery mileage since you thought you are saving battery by going slower but you actually wasted a lot of power there. Most of the time, I notice that simple controllers feel "punchy" and tend to lurch ahead from a dead stop (great for showing off to friends) but once the ebike is already moving and you needed more assist, sometimes the power isn't there anymore, when you needed it the most.

Enter the Smart Controllers from the big players where more brain capacity is added to the controller's program in order to determine and match power requirement with the power output of the motor. And added measures are incorporated to cut the assist if the motor speed is at the inefficient range. This is made possible with the use of torque sensors and sophisticated program algorithms. An example of this is the "dynamic assist" from Juicedbikes.

http://juicedbikes.com.au/bikes/2017-crosscurrent/

As a general rule, the most sophisticated controllers take full advantage of the torque sensors and measure the rider's effort each millisecond (a thousandths of a second) and convert that into specific power to the motor based of the assist level. These are popularly called as "Proportional Assist" system.

It only goes to show that it's not only the motor efficiency that is important but how sophisticated the controllers are made. Not all controllers are created equal.

On mid drives, the gear reduction ratio is also set up so that the motor is most efficient at a cadence rate preferred by most cyclists (normal cadence range) .

https://www.electricbike.com/bosch-cannondale/

This principle in actual application made it possible for a small motor (mid drive) to achieve a very very impressive efficiency of 100 miles in 1 charge of the 500wh battery or 5 wh/mile!

https://electricbikereview.com/forums/threads/range-100-miles-giant-road-e.14617/#post-121767

This highest mileage potential is demonstrated by the small mid drive, but at a slower average speed (~15mph). The mid drives also has an advantage for the ability to climb very steep hills, as long as the gear ratio in the drive train is appropriate, but at the expense of even much slower, snail paced, speed (sometimes it feels like being pulled up by a winch!).

However, hub drives are not far behind in efficiency. Especially with increasing sophistication of the controllers and more efficient motor designs like the Maxon.

http://partir-en-vtt.com/fsb2/index.php?p=search&mode=author&id=52

https://electricbikereview.com/forums/threads/hub-vs-mid-drive-how-can-i-compare.14635/page-5

Hub drives are also more appropriate for high speed commuting, such as riding regularly at higher average speeds (above 23 mph) since the bicycle drive train at that higher crank output will wear out prematurely in less than a couple thousand miles. Or for transporting heavy loads such as the delivery ebikes.

There is still a bright future for efficient hub drives since, aside from the above mentioned strengths, hub drives are also very user friendly, easy gear shifting, durability, and is superior on stop and go city streets.

Last edited: